Good podcast? Give it some love!

Siemens

Where Today Meets Tomorrow

Good podcast? Give it some love!

Rate Podcast

Episodes of Where Today Meets Tomorrow

Mark All

Search Episodes...

Siemens Digital Industries Software is launching a new podcast – The Battery Podcast. Understandably, our hosts and guests will be discussing the battery industry as a whole and the many components that create it. The goal is to talk to experts

PLM for cloud is changing the product development process and having a fundamental impact on the way a business operates.In this final podcast of our Teamcenter X solution, Mary McDonald, Global Industry Marketing Leader for small and medium b

PLM for medical devices covers the need of all teams involved in the whole product life cycle, from the device design development to the production and finally to regulatory submission.In this fourth podcast in the Teamcenter X solution seri

This podcast discusses how the cloud changes the product development process, fundamentally impacting how a business operates. Machine builders can blend their engineer-to-order (ETO) and configure-to-order (CTO) demands. Engineer-to-order (

Amazon Web Services (AWS) is architected to be the most flexible and secure cloud computing environment available today. The core infrastructure is built to satisfy the security requirements of the military, global banks, and other high-sensiti

Software as a Service (SaaS) is a way of delivering applications over the Internet. We have all become users of cloud solutions, often starting with our mobile phones and backing up data to iCloud or Google Drive. However, SaaS applications hav

An increase in the complexity of designs has led to the adoption of more advanced technology in verification. This is helping companies increase their efficiency and keep the cost reasonable as they meet the needs for more customized products.

Increased electrification and customization have significantly increased the complexity of ASIC hardware design and verification. This has resulted in many projects taking longer period than expected. That’s why companies must develop more eff

The increased complexity in FPGA design has also increased the complexity of the verification process. Organizations are now looking to leverage new verification techniques and languages. While more tools and languages are now available for ver

Increased complexity is one of the biggest problems that manufacturers are currently dealing with. One of the biggest causes of this is increased electrification and the need for customized products. Adding features to cater to those needs requ

What is the future of innovative technology and manufacturing? Siemens is on the pulse of groundbreaking technologies. In step with that objective, Siemens Digital Industry Software Thought Leadership Team provides podcasts, blogs, articles and

Low-code was not built as a full replacement hard coding. In fact, in most cases, it complements it by accelerating the software development process. It therefore shouldn’t be viewed as the answer to everything even though it’s a perfect answer

In safety-sensitive industries such as aerospace, management needs to keep detailed logs of all their processes. This makes the industry very cautious when adopting any changes. They don’t just run towards the next flashy innovation before thor

Most established organizations are very protective of their legacy systems even when they are clearly inefficient. That’s because their employees’ vast knowledge on how to operate those systems is a big asset to them. They view investing in ne

Change is inevitable for any organization looking to remain relevant or progress. However, implementing it is not easy because people who are used to doing things a certain way will likely view it with suspicion.This is one of the biggest obst

Low-code helps companies build applications faster without the need for a large specialized team to start the process from scratch.That speed is just one part of low-code’s magic! Another factor that makes it stand out is the flexibility that

Low-code platforms are a great solution when you want to achieve accelerated digital transformation at a lower cost. But, can it really work for big industrial environments? How do you get from problem to solution?First, yes it can. Low-code i

Manufacturers are surrounded by data but are starved for insights!In an age where quality-first culture can mean huge profits and increased market share, using data to achieve continuous improvements has become very necessary. However, this is

The cost and value attached to legacy systems represent the biggest impediments to digital transformation for most manufacturers. This is why most of the companies that feel the need to digitalize so as to keep up with current consumer and mark

One of the most impactful steps that manufacturers can take to set themselves apart is by making quality a priority in every process related to the product. Failure to do this can lead to costly recalls and loss of market share to competitors w

Cost has been historically considered an important driver for every business, and sometimes choices to reduce it have been made to the detriment of ensuring quality. But, on the flip side, ensuring quality is the best way to control unexpected

Quality in a product is not only what the manufacturer puts in. It is what the customer gets out and is willing to pay for. It has the potential to make or break a business in today’s highly competitive environment. This is why a company should

Increased electronics complexity has directly impacted all stages of the design and manufacturing processes. This comes at a time when companies are being pushed by market forces to cut the time to market and still make quality products at affo

As electronics become more complex, the task of designing has become more demanding. Improvement of a single component in most cases requires a change of several other components and subsystems. To achieve this, companies have had to shift from

There is nothing more costly than doing efficiently that which should not be done at all!In today’s market when a shorter time-to-market is demanded, this is a situation that has to be avoided at all costs. This is why most manufacturers are n

Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

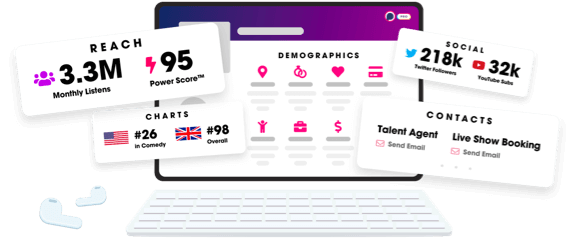

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us