Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:00

Music.

0:12

Sitting a stand out east this is about passion pursuing

0:15

our dreams of field our lifestyle the betterment

0:18

of self and community the enlightenment that comes from those

0:21

moments spent in god's creation through these conversations i hope you find

0:25

insight inspiration education and motivation to push beyond your limits all

0:29

right so we're on with uh some folks over at uh vp archery i'm pretty excited

0:34

i stopped by the booth at hun expo and as busy as it is there and it's kind

0:38

of a And at least in my opinion, a consumer based show for y'all.

0:43

So I didn't want to, you know, take up too much time and do too much brain draining.

0:47

And I think when I was over talking to Alex, it was, I don't know,

0:52

10 minutes or so before the announcement of we're closing the door.

0:55

And as soon as I heard that, I just ran.

1:00

It's a nut house. Yeah. So we're able to get on.

1:03

And, uh, you guys had, you know, we had shared messages back and wow,

1:08

I think it was December and I responded and it just fell to the wayside,

1:12

just trying to keep up with the stuff that comes through an Instagram.

1:16

So I was like, oh my goodness. When I saw it, I was like, I feel like such a

1:19

a-hole, but nonetheless, we're here to talk about one of my favorite topics and that's archery and get

1:26

into what you guys are doing at advantage point and some of the beautiful broadheads

1:31

you guys are putting out there. So why don't we start off, go ladies first with intros and give us a little

1:36

background, and then we'll just roll from there.

1:40

Alex froze. I think just over two years now. Start over. Did you lose me?

1:45

Yeah, we lost you. You were frozen there. Got me. Got me. Yeah, you guys are breaking up on me too. So hopefully it's not my connection.

1:57

Okay. Yeah. My name is Alex Christensen. I'm the marketing manager here at BPA.

2:01

I've been here for just over two years now. So I'm actually new to bow hunting.

2:05

I've always grown up in the outdoors and with a family that grew up hunting

2:10

out west actually and moved over to Indiana.

2:14

But this past season was my first season bow hunting and I love it.

2:18

It's been so fun to get into through working at BPA.

2:21

So yeah, that's a little bit about me.

2:25

So why, why go from the West to Indiana and then start bow hunting?

2:30

That is my first question. That might be the most pressing question of the podcast.

2:36

You can end the podcast with what she answers then.

2:39

I've basically grown up in Indiana, my whole life, Indiana, Kentucky.

2:42

So my parents are both originally from Utah and my grandparents and parents

2:46

both grew up hunting and kind of when we moved out here, it wasn't as prevalent,

2:51

I guess. And they just didn't really keep up with it. So it wasn't something I really grew up doing.

2:55

I was more involved in sports and things like that.

2:58

But it's been fun since working at VPA to get back into it and kind of the whole

3:02

family getting back into it, too. So it's been pretty awesome.

3:05

Heck, yeah. Kind of spawned it, spurred it back on for everyone.

3:09

It did, yeah. Yep. That's good. Go ahead, Brian, all you both.

3:13

All right. Brian Poe, I'm the sales manager at VPA, and I've been here since

3:17

October. had about a 35-year manufacturing career, about 30 of those in orthopedics,

3:25

which is huge in Northern Indiana. But I was made the offer by the fine folks at VPA and actually turned it down

3:31

for a while just because of the change, had nothing to do with the people and the opportunity.

3:35

But my kids all thought I was out of my mind. They're like, you can go to a

3:40

bow shop or a gun shop and talk as a hobby.

3:42

Now they want to pay you to do it. So when they put it like that,

3:45

it made a lot of sense. but really glad I came on board.

3:48

A lot of good people, a lot of integrity, a great team, doing a lot of good

3:52

things, good period of growth right now. So I've been bowhunting. I just finished my 38th season here in Indiana.

3:58

I've only bowhunted whitetails. I have never hunted anything else.

4:02

I had opportunities at turkey and small game, but I don't know,

4:06

to me, bowhunting whitetails is as good as it gets for me here.

4:10

Now, opportunities to come out west and chase elk,

4:14

even caribou down the road or something i am all in

4:17

to do but for here in indiana to me there's nothing like white johnny white

4:21

i mean with a bow and and generally speaking right out of a blind or or a stand

4:26

yep there's something yeah there's something to be said about the ability to sit in a tree stand.

4:37

Deal with the weather you deal with in that fall season there.

4:40

And I mean, it, we, you know, a lot of Western guys will poke fun at down South, back East, right?

4:46

Sitting in a stand, man, was it last?

4:49

No year before last we go, we went down to Texas, a buddy of ours managing a property.

4:54

And I sat in that stand and couldn't believe the mental fortitude that it takes

5:01

to sit through a 10, 11, 12 hours sit.

5:05

It it is on and you can you can

5:08

think you're in the best shape of your life until

5:11

you get into a freaking tree stand man it is rough yeah especially some of the

5:16

temps and our early season temps will be 70s i mean we've had opening days of

5:21

archery october 1st where it's low 80s and then we're below zero with windshields

5:26

you know by november december sometimes so we see it all yeah yeah and And then,

5:30

and the whitetail are switched on and it's like, they're switched on all the time.

5:35

Yeah. Right. There's no, there's no going out and we may catch one,

5:39

you know, maybe if it's in the rut, he, he's not looking up at some point,

5:43

but I was sitting in the stand. I'm watching pigs and deer, but I can see them coming and they'll stop.

5:49

They'll look right up at me. I haven't moved. And I'm like, they know the position of the stand.

5:55

It's the craziest thing, man. And there's a lot to go into planning that hunt.

5:59

Right. and where you're putting your stands, you know, and your wind on the

6:03

properties and whatnot. So I think it's pretty cool. It's definitely a bit different than what we're

6:08

used to here, but there's so many similarities when it comes to the mental game

6:12

and the wind and yada, yada, yada.

6:14

I mean, super fun. We're actually leaving for Texas, I think Thursday or Friday this week.

6:21

Going to take some of the single bevels down with us and see if we can't put

6:25

a hurtin' on some exotics and some hogs down there with them. So pretty exciting.

6:29

For that yeah that'll be awesome yeah so

6:33

let's talk vantage point so you know where

6:36

when who what how the whole nine on vantage point let's get some get some history

6:42

on the company and maybe some of the product line that folks would know about

6:46

i know you guys have been pushing and it seems to be kind of you know blowing

6:50

up a little bit but give us the who what wins and everything mm-hmm.

6:55

Yeah, so I can go ahead and get us started. So we're actually a machine shop

6:59

and we still have that part of our business, Absolute Machining.

7:03

They're on for over 20 years now.

7:05

So one of our head machinists, Jeff Miller, who's still with us,

7:09

was a big traditional bow hunter and just wanted to make his own broadhead.

7:12

Saw the need for a more durable American-made head in the market.

7:17

And I think our first head was a three blade 150 grain, maybe just a solid head,

7:22

pretty simple and word of mouth spread.

7:25

He gave it to his friends and it really just went from there.

7:27

So that was about 2008, 2009.

7:30

And then the past couple of years, we started selling online and getting into

7:34

a lot of bow shops and really just been growing like crazy. It's hard to keep

7:38

up, but it's been awesome. That's a pretty stout head to start off with but that that goes right in line with that that trad,

7:46

set up there yeah yeah that's really

7:49

our following started out in the traditional community and we

7:52

still have a ton of traditional you know customers but

7:55

really crossbow and compound and a little bit

7:58

everything so it's been fun to kind of see it evolve to

8:01

a little bit over time and you guys

8:03

still making a 500 grain i think we

8:08

do we don't sell it on our website i think we have a customer who

8:11

who wants one made yeah and gets it occasionally so

8:15

we carry carry on our website 100 to 300 right

8:18

now is what we offer okay yeah i was looking at that i

8:21

was looking at the pack you guys sent me here and it was up to

8:23

350 so i was like huh i mean there's and

8:26

there's plenty guys that are still out there and gals shooting you know

8:29

that that 500 out front there yeah for

8:33

our compounds i i don't i don't i didn't

8:36

even ask you guys so compound or trad compound yep

8:39

compound for me as well okay so we're all smart on here

8:42

why make something why make something exponentially

8:46

diff more difficult and we don't have to oh i'm still learning just how to get

8:52

out there and bow hunt with the compound bows i think it'll be a very long time

8:55

before i jump over to that side if ever yeah i keep i keep saying i'm gonna

8:59

grab a trad bro bow and every Every time I think about doing it,

9:04

I look back at my season and go, nah. Yeah. You know what? I have an obsessive personality.

9:10

I'm the person that if I start something, I want to be at least good at it.

9:15

I may not be the best, but I want to be what I feel like I'm satisfied.

9:17

And I know where that would lead. If I picked up a trad bow,

9:20

I would be out here for hours.

9:23

Worse than I am a compound, and I don't have time for that. Yeah,

9:26

no. I'm just staying away from it. You and me both.

9:29

Yeah. Yeah. So, so how did, you know, where did it come from?

9:33

We kind of talked about where it started. What, what makes you go, we're going to dive into this, this realm of broadheads

9:40

and then in the market today, say we're going to ramp up our line,

9:45

expand our line and really make a push towards the market.

9:48

I mean, it's one would say that it's saturated a bit. What, what sets VPA apart, etc.?

9:56

Yes. So I guess what sets us apart is easy to start off would be just American made.

10:01

It always has been. We always will be. All of our broadheads are done in-house

10:04

and, you know, in our machines. We have about 30 employees working in our machine shop. So we consider that

10:10

30 families we take care of.

10:12

So we're very serious about, you know, USA manufacturing and growing,

10:16

you know, in that area too. We make our own broadheads. We actually machine other Other archery accessories

10:23

like ILF risers, we do some small game heads, field points, stuff like that.

10:28

And then we machine products for other companies in the archery industry,

10:32

firearm industry, and stuff like that. So really everything we've done has been based off customer feedback and just

10:37

seeing what the need is in the market and expanding from there,

10:40

expanding into the two-blade stuff. And most recently with the single bubble has been the trend over the past couple of years.

10:47

So that's been the most recent expansion. but but

10:50

yeah customer feedback is kind of what drives us brand

10:54

new man yeah we and then the beautiful thing

10:57

is too in addition to manufacturing everything in-house which

11:00

when we've gone to trade shows people are so impressed

11:03

with that they just think you're a standalone broadhead company and that's

11:06

it and they're so impressed with the fact that i call

11:09

it our parent company absolute blue machining we make

11:12

our own stuff and we make stuff for other people

11:15

too without getting into the details so you know

11:18

we're a premium product we're sourced in

11:21

the usa as well so not only do we have usa manufacturing but

11:24

we source our material in the usa and that's really

11:27

big that was a real push for me

11:30

when i first started shooting vpa heads which was a few years

11:33

before i started working here and then

11:35

since then i've just seen a dedication to that usa manufacturing

11:39

and sourced and that's i'm all about it and if we can't get

11:41

behind that i'm not sure we can get behind yeah that's

11:45

i mean it's a pretty big deal right you know just like

11:48

alex said right you're supporting all those families with

11:51

that effort so yeah and decades of bad

11:54

policies decades of policies you know

11:57

with with sending things to china and unfortunately we as

12:00

consumers are to blame too we like cheap stuff and for a

12:02

long time we thought hey it's cheap but cheap and we never thought.

12:05

About you know decades down the road where it would end up

12:08

so i mean a lot of people are really impressed

12:11

also with our usa manufacturing i've only had a couple people

12:14

say and my customers don't care everybody else

12:17

has said hey we're all about that we want to work with you

12:20

guys just because of that if nothing else i think to a point that i mean there's

12:24

there's truth on both sides of that right i think a lot of people say it and

12:29

don't necessarily for convenience for finance follow through with with that

12:35

right and and the convenience part of it.

12:39

I'm going to have to disagree with that approach. Finance part of it, I can get it.

12:45

But buy once, cry once is kind of my belief when it comes to,

12:48

especially things I take out into the field.

12:50

Yeah, well, and if you look at even our price structure, we've got price point

12:54

heads. You know, like a three-blade 100 grain.

12:56

It's not much more than a G5 Montech. It's not. And it's a way better head.

13:01

It's not mem, one piece of machine, bar stock.

13:05

And it's just a better head all the way around. And it's very,

13:07

very comparable in price. So, you know, some people say that the price thing,

13:11

but they also look at maybe your premium heads or your top shelf heads.

13:15

And that's what they look at. Well, not everybody can't afford those. I get it.

13:18

I've been there myself before, but you can still do better, I think,

13:22

than what a lot of people settle for. Absolutely. So, so neither one of you touched on how crazy is everyone at VPA

13:31

for stepping into this realm and, and upping a product line, right?

13:37

I mean, it takes, it takes a lot to look at, to look at our industry and say,

13:41

this is the approach we're going to take.

13:43

So either you're crazy or you feel like the product is top shelf and it's better than X, Y, or Z,

13:50

and no offense to anyone else, to really step out and say, hey,

13:54

we're going to go, you know, Alex is on, cojones to the wall in this realm.

14:03

What's that decision process? Because you look at it and go,

14:07

well, wow, don't we have enough broadheads? Alex, you want to start it? Sure. I guess going back to what we mentioned,

14:15

we take the customer feedback into consideration. And then typically, our team meets.

14:19

We don't have a big team, so we wear a lot of hats. That's for sure.

14:24

So we are crazy when it comes to adding a lot of new products and keeping up

14:29

and pushing ourselves to expand into not even just broadheads.

14:33

More recently, we expanded into the firearm industry with pistol compensators,

14:37

which you probably saw at the show. But a little bit of everything so really it's just kind of

14:42

doing our research and and putting those

14:45

numbers together to see what's worth you know the

14:48

investment for us to develop a new product put it out in the market it's a lot

14:51

of time and testing but i don't think everyone realizes how much r&d gets put

14:56

into a broadhead even if it's just a different grain weight we still want to

15:00

do thorough testing to ensure it's going to hold up you know the test of time

15:04

and all the different tests they put it through yeah,

15:07

So just, I think, sorry, go ahead. No, no, no. After you.

15:13

My, my thinking is, had I been offered this position back in October and I wouldn't

15:18

have seen not just the Omega from last year, which I used this last season successfully,

15:22

it works really, really well. But all of the things that they'd listed during the interview process,

15:28

we're doing this and this and this and this. And plus we want you to bring more in. We want to grow this thing.

15:33

We just sat forward looking, you know,

15:37

mindset is really what attracted me also if

15:39

they would have said i just come in you know it's the same heads

15:42

and just go out and sell those things and good luck i don't know if i would

15:45

have accepted the position to be honest i think it would have been maybe boring

15:49

and flat and just not as fun to even have maybe design input in certain projects

15:54

and again we have a great team everybody listens to each other even if you disagree

15:59

and we're we're okay with disagreeing with each other,

16:02

and you know and it all comes down obviously to ownership with decisions they

16:06

want to make but But everybody is open to listening.

16:09

And I don't know if that makes you crazy or just different, but it's been effective.

16:14

And there's huge amounts of wisdom in that, right? Especially if you have a diverse team of people.

16:21

I think that's, that is, it's a little crazy, right? When you look at the offerings

16:26

and go, we're going to slam the market. Yeah.

16:29

But there's wisdom in taking customer input, your R&D input,

16:34

the folks that you bring on input. It's huge.

16:38

Um so talk about the r&d process a little bit and then i want to get into some of the heads,

16:44

how does that r&d process look like what do we how are we testing different

16:49

steels are we testing edge retention hardness you know is it gelatin and ballistic

16:55

testings things like that how does that all look,

16:59

Go ahead, Brian. Cow bones and, gosh, what is it?

17:04

OSB, layered OSB, shooting at close range distance in the field also.

17:12

You know, our products are sent out to testers to see how they react on real animals.

17:17

You know, gelatin's great. It kind of gives you an idea of how something's going

17:21

to react. but there's nothing like bone tissue, organs, fur from different animals to provide feedback.

17:29

That's the big one.

17:32

And OSB is as scientific as one could get.

17:38

It's a pretty hard, you know, that stuff's pretty hard, you know,

17:40

with the glue they put in there. And so we'll shoot it at angles and we'll shoot it through and through and check

17:45

it after penetration, see what the edge looks like. And our S7 stuff rockwells

17:50

at 56, 58, which is a pretty hard hand.

17:54

And so it holds up really well, the edge retention.

17:57

Not just in testing through cow bones, OSB, etc. But I got pictures and I showed

18:02

them at our trade show season here to people.

18:04

And I said, this is the Omega after I blew through my buck.

18:08

Scroll over. This is the three blade after my son blew through his.

18:11

And we had a really good season this year. This is my son after he blew through his. is.

18:16

And I'm blowing these pictures up and they're just mind blown at the edge that's still there.

18:20

I would still hunt with every single one of them that we shot deer with this

18:23

year. I would put it back in the quiver and hunt with it and not have a guilty conscious for it.

18:28

We don't, we do touch them up before we put them back in the quiver,

18:31

but yeah, they're, they're, they're just, they're just solid heads.

18:35

And the, the edge retention is just second to none as far as we know what I've

18:39

seen over the years. And then how does that honing look with that, with that hardness?

18:44

It's you know i always say that sharpening is some

18:47

people have the patience for it some people have a little you know skill

18:50

to it a feel other people hate it with a passion

18:53

i end up sharpening all of our heads my son-in-law my three sons before season

18:56

they don't like it i enjoy it turn on the music and just sharpen some can be

19:01

a little tougher than others but you what i do is i put it i put it aside i'll

19:05

go to the next one so you're not trying to overwork it get frustrated set it

19:09

aside, work on another one, and then go back to it. What I found last year, interestingly enough, and I was talking about this to

19:15

one of our owners recently, I found that before this last season,

19:19

our three blade heads, I worked those right down to a strop and got those hair popping sharp.

19:25

A couple of the single bevels, if I stropped it, it felt like I lost that razor edge.

19:31

So I went back to the 2,000 grit and 1,000 grit sandpaper and left them.

19:36

And they were just hair popping, shaving the paper. So I think some people get too caught up in a process and

19:41

you've got to think your way through stuff sometimes and go,

19:44

okay, this one worked like this.

19:46

Don't say this one has to, it's different.

19:49

In Rockwell, a 56 to 58, maybe one's 56, one's 58.

19:54

And if there's any tolerance in there, you deal with that also.

19:58

But as far as getting an edge on them, it's not an issue, especially with the

20:01

Omega, the lay flat technology, no jig needed.

20:05

You just lay that that thing on the, uh, on the stone and go to work with it.

20:08

And that, that thing was fun to sharpen this year. I enjoyed that.

20:11

So I'm going to just pull that up. Right. So if anyone is listening that are

20:14

watching, you can see on the ferrule that is on the same, call it plain as the bevel.

20:23

So instead of having to hold that on edge to get that, you run that flat and

20:29

then that's going to help you align that bevel as you run it up on that stone.

20:33

There so when i mean guy when you when you turn that

20:36

to the back side then there's a little micro bevel on

20:38

the back side that also matches the ferrule so when you

20:42

get that edge where you have a nice little burr and you turn

20:45

that over and you drag it maybe on sandpaper or

20:47

strop whatever you're doing to finish it that thing

20:50

just it's it's unbelievable how if i can

20:54

can you yeah yeah you can see it there there it is

20:57

yeah and that was that was one of the

21:00

things when alex handed me me the pack and you know we started talking

21:03

about that at expo there i was like oh wow somebody actually

21:06

thought beyond the bevel in

21:09

terms of getting that honed and sharpened and that

21:12

was that was immediately a standout for for me right it was like that level

21:17

of thought process went into the end user i gotta look at this product in a

21:24

in a brighter light it just yeah and it's a i I mean, it's a great looking head. I weighed everything.

21:30

Everything was right in that 0.01 grains.

21:34

So everything, and then width-wise, money, length-wise, money, ferrule, money.

21:41

So consistency, and that's one of the things that drives my purchase,

21:46

especially when it comes to broadheads, arrow components, is consistency across the build.

21:52

I'm anal. When I build an arrow, I'm meticulous about how much glue I'm using,

21:57

where everything is going. If I'm building a 200 or excuse me, a 535 grain arrow, that's what this one is here.

22:04

I want another 11 coming out at 535 grain.

22:09

And I, the last dozen I built, I screwed up to one of them.

22:13

And I can't, the one I was trying to figure it out yesterday and it's.

22:20

547 for the life of me, I cannot figure out why it's 547 grain.

22:27

And the only thing that I could think of is I, I think, I think that I inadvertently

22:32

put two inserts in there. It inserts.

22:37

Yeah. And I think that's what accounted for because it's almost 10 grains. Exactly.

22:42

Right. My glue. I mean, I'm so meticulous on my glue.

22:45

So it's the only thing I could think of. So I'm going to deconstruct it.

22:49

The best i can and i'm gonna figure it out because it

22:52

came out i mean it was 547 and i was

22:55

just like this makes zero sense i pulled components off weighed the components

22:59

everything is jiving and i do a full spreadsheet like i'll go through i'll go

23:04

sometimes i'm embarrassed telling telling i'll go through and i weigh i weigh

23:10

each vein i weigh each individual vein and i'll create a pile tile, right?

23:15

If we're, you know, call it five grain, six grain, 7.28, whatever it is, right?

23:20

And I'll match those through there, depending on how those land 10% here,

23:25

40% here, 40% here, 10% there, then my 10 percenters going to be my cock veins, right?

23:32

And then the other that's going to be, you know, and then I try to build a consistent arrow across the board.

23:39

If I'm pulling I'm pulling out the five, I'm pulling out the seven, I'm pulling out the eight.

23:42

They're going to go on every single arrow the same.

23:46

The best I can to have the same build plus or minus a couple grain on each single arrow.

23:51

So I have no idea outside of putting another insert in that SOB that I gained 10 grains on that one.

23:58

It was pretty interesting. Well, that's going to drive you nuts,

24:00

so you might as well just go and work on that tonight, right?

24:04

The deconstruction has started. started some of the

24:07

some of the glue i should have hot melted them in there i

24:10

haven't had a ton of luck with some of the hot melt in the arrow for some reason

24:16

it seems like i always snap loose so i tried a lighter epoxy so i have it soaking

24:23

so i can see if i can't get the the hits out of there and see if that's what

24:27

screwed me up but i think it is. Okay so we were talking i'm sorry we were talking about r and d

24:34

so what what's your what's your yes we're

24:38

building it no we're building it factors when it comes to the heads right say

24:41

we're testing out a single bevel how many you know iterations did you guys run

24:45

through with that single bevel was that you know due to the point was that due

24:49

to the edges how does that look before you say okay it's going to market or

24:54

we're scrapping this idea. There's never a set of integrations we go through.

25:00

I know with the Omegas, we actually worked with Daryl Barnett to design the Omega.

25:06

Like you guys were talking about, the feedback was sharpening.

25:09

Some people just hate it or don't like the time it takes.

25:12

So that was the driving factor to design the Omega, which we launched in July,

25:16

I believe. And it's been our number one seller since then.

25:19

So huge success with the Broadhead and for obvious reasons, just super super

25:23

easy to sharpen, but still getting those characteristics of a single bevel that everybody loves.

25:28

But that broadhead went through several iterations to figure out what we wanted

25:34

from it to get the sharpening perfect, to be as easy as possible.

25:38

Because there were different things we could do, but it's a patent pending head

25:42

too. So a lot of the features on there were very meticulously chosen.

25:46

It's got the tanto tip there, the bevel angles and all that good stuff.

25:51

Stuff so brian you can probably talk more about the the testing of it at least

25:55

yeah and then also the wedge on the opposite side so i'm not sure can you not

26:00

catch that so basically anything that that gets in the omega's way you know

26:06

is it's going to have to get out of the way so i think.

26:10

Some of that also can be attributed to i think if you have really smart people

26:15

who understand geometry who have hunted and killed a lot of stuff and then you

26:20

add somebody like daryl barnett kind of known as Rocket Man is what people have

26:24

called him on the internet, but super smart guy with flight characteristics and aerodynamics.

26:29

And when you put him to it along with our people, you apply that science to a lot of experience.

26:34

And not that you don't test things, obviously we do, we test it,

26:38

but that kind of cuts out, I think, a lot of trial and error.

26:42

I know there were different iterations with our heads, but if it's something

26:46

that's real science and it makes sense and it actually has functioned in the

26:50

past or something similar. Maybe you're just kind of tweaking a design along the way. You know,

26:55

I think it just makes sense. It's an easy go then. Heck yeah.

26:59

Bear with me here. I'm scrolling too. So one of the things that I like that

27:05

I noticed was this custom test pack, right?

27:08

So if you're a tinkerer or somebody that wants to see, you know,

27:11

what your preference is, you guys have a custom test.

27:15

I think it's a three pack. Yeah, three pack of broadheads. So you can go from

27:18

a solid to a vented to a single bev.

27:21

And then mix and match your weights there. That's actually, again,

27:25

for an end user, like why wouldn't I go down that path to understand what my

27:33

bow likes to shoot at the front of whatever arrow it is that I'm building at the time.

27:39

And it runs through the entire product line. So you get to select three heads

27:44

of your choice, be it the single bevel two blades, the lefts, the rights.

27:51

Three blade vented, three blade solid. I have my opinion of vented.

27:57

I'll shoot a turkey with them. But I thought that was pretty cool.

28:03

When it's someone like me that wants to see, right?

28:06

I mean, it's an expensive endeavor.

28:10

I don't know why that was a tongue twister, but it's an expensive endeavor,

28:13

right? So, you know, you spend all this time, like I said, I'm anal about my builds.

28:16

So I fashion all this out on paper. I put it together. I get a broad head.

28:21

And now I've spent a hundred bucks, you know, on, on a three pack or whatever it is.

28:25

And I don't like the way they fly on the front of it. I could test this out early on.

28:31

Yeah. That's a great flipping idea in my opinion.

28:35

Yeah. And we actually, we wanted to do that for a while and just,

28:38

you know, it's just something we got around to more recently putting it on the

28:41

site, but it has been popular, especially for a lot of those people coming from maybe a mechanical who have

28:47

absolutely no idea if if they want to shoot a three blade or they want to try

28:50

and just jump, you know, head first into the whole single bevel game.

28:54

So I think it's a great resource. And then we also offer the field point test

28:58

kits too, for people who like to tinker around with maybe different weights.

29:02

So it's just a pack of field points that has one of each from a hundred grain,

29:06

all the way up to 300 grains, you get a 100, 125 and so on.

29:10

So you can kind of play around with different field point, you know,

29:13

grain weights and figure out what. Grain weight you want to shoot before the season starts and before you buy your broadheads.

29:19

Okay. And then you guys have that crazy looking, you got to,

29:22

so walk, I'm sorry, I'm jumping all over because I'm on the website right now.

29:26

So you got to walk me through the three blade 125 turkey spur.

29:30

So that is, that's an interesting looking setup there in terms of a broadhead.

29:36

So I'm curious now that I've seen it. Yeah. So that's designed just to create drag and, you know, Sticking the turkey

29:42

versus a full pass through. I think we've actually got some exciting things we're working on this year with

29:47

that, just based on feedback and different things we've wanted to do over the years.

29:52

Because that has been around for several years now, and that's been a popular

29:55

one, too. We offer it in 125 and 150 grain.

29:58

I haven't got to shoot that one yet. Brian, you're not a big turkey hunter, so you haven't got to shoot that one. I'm not.

30:06

Okay, so the rear. What is it? Super cool videos with that of customers shooting it.

30:14

So the rear blade is only edged on, call it the top of the blade,

30:20

in line with the main blade, correct?

30:24

And the other is flat face and that's what drags the drag through there? That is interesting.

30:29

I mean, it makes sense. That's what I mentioned, like with the really smart people that we have that

30:35

design these things. It's just, you know, you apply science and some common

30:39

sense and experience and you get good stuff.

30:42

And that's a hard one. I mean, you know, unless you, unless you are lopping off heads at the neck,

30:49

you know, you're, you're really, you're really looking for a bird on the run,

30:54

especially when you get out of distance with those, with some of those bigger boys.

30:58

And, and, well, I won't say what my favorite shot with a single bevel on a turkey

31:02

is to get them to drop at eight yards consistently.

31:07

That is a really good idea that's pretty interesting,

31:12

And I'm not a fan of mechanicals much anymore. I used to love them.

31:17

I had a couple of bad instances, and I'm like, no, thank you.

31:21

Yeah, I'm with you. You know, I grew up shooting fixed. There was no such thing

31:26

as mechanicals when I started. I mean, to back up completely, we shot bows with 50-pound, 55-pound draw weight and 50% letoff.

31:35

People would die if they tried that now. They're used to the 90% stuff.

31:38

You're holding 25, 27 pounds and didn't know any better.

31:42

And, you know, we shot the XX-75s, we shot the Bear Razor heads and Zwicky heads, 150, 160 grain.

31:49

Our arrow weights were 500 grains back then, even on pretty short draw lengths.

31:55

And we're pulling this, holding stupid weight. And you know what I never heard

31:59

was, did you get a pass through? Never. Never. It was just a given. We never worried about penetration because

32:06

science is real and that's a whole separate rabbit hole.

32:10

But the point is fixed heads just work and they worked for years for me.

32:14

But I jumped on a mechanical thing for a few years at two bad situations and said, I'm done.

32:21

And then that's when I got hooked up with VPA and started shooting those.

32:24

And I'm, I'm, yeah, I'm, I'm done with mechanics forever.

32:28

Ever yeah yeah and like i said i'm a

32:30

i've been a single bevel guy for a while now and i

32:33

mean just the wound channel that it creates and then

32:36

the even in my opinion of it right even if i don't get the full pass through

32:41

and i and that arrow's sticking out the devastation it's going to cause as it's

32:46

twisting it has to twist back out or pull across flesh that's not cut it's just

32:52

damage in in damage out either way.

32:55

Yeah. I, I love them. And then you guys got these crazy.

32:59

That's what's interesting is like, you look at the Turkey head and then these

33:01

small game thumpers and it's just like, well, that just makes sense too.

33:07

Looking at the wall see the 175 oh that's a glue on i was gonna say why does

33:12

that look like that but that 175 with that kind of concave tip on that thing

33:17

i mean that is that's taking energy,

33:21

and and literally driving that energy in and through versus having something

33:27

with a rounded broader tip that dispersed that energy and tell me if i'm wrong

33:31

in that design just looking at it That's what I see when we talk about on-impact stuff there. Yep.

33:40

That's going to be in my quiver for my grouse for September.

33:45

I always got to have one for the grouse. Although Brian wouldn't know about

33:49

that because he doesn't want to come hunt out west with us.

33:53

Oh, yes, he does. He does. I do. I will.

33:57

I will. you want if you want

34:00

your life ruined forever come out

34:04

in september and get into some

34:07

bowls you you won't have to kill a

34:09

thing all you need to do is hear a couple bugles a couple

34:13

yeah the job that i'd

34:15

left here in october some guys there elkhart caribou

34:19

regularly they go out west and alaska and canada and

34:22

they said the first time one guy

34:25

told me the first time he ever went he didn't get a shot and sometimes

34:28

he forgot he was even there to get a shot he was just watching

34:31

the action listen to the bugles listen to the calls

34:34

and you kind of get lost in it you get nap out

34:37

of it go i'm here to hunt you know and get back in your focus again and yeah

34:40

he said once you do that you'll never you'll never look at it the same and you

34:45

you can never avoid it like it has to be an every year thing i mean it just

34:49

it is it is heaven in a bottle every September.

34:55

So outside of the... I'm sorry, man. Outside of the broadheads,

35:00

you guys do components or anything else, you know, like that? Sleeves or...

35:05

Yep. Collars? Yep, we have the footers that we machined.

35:09

Yep, yep. And then the, let's see, the small game heads we do for all grain

35:14

weights. We do still, like you mentioned, offer some glue-on options.

35:18

We also do have some glue-on options for blades, too, for some of the tread

35:23

that will have whims on the market. We are working to expand and actually offer like a 15 and 17-inch,

35:30

hopefully this year, in the riser, too, to kind of expand that product offering.

35:36

But yeah, a few other exciting things we're working on this year.

35:39

Hopefully we can, you know, say more about it here in the next couple of months

35:43

as we get closer to season. But it should be a great year.

35:46

So what size arrows are you guys covering in the footers?

35:50

It's in the 205 range. It's in that neighborhood. I've used them on RIP TKOs.

35:55

I think, aren't they technically though, Alex, they're for the FMJs, different size FMJs.

35:59

But yet if you just match up the ID with the OD of the arrow you want, I've done that.

36:05

And they work they work great yep and you guys are you guys are machining all that too huh.

36:12

Yeah i'll pull those up real quick so size so okay so yeah size for that also

36:18

compatible with the od of 0.263 dangerous name bearers game heck y'all have to look at that,

36:25

and then any any inserts or hit inserts things like that coming in the future.

36:33

Yeah, we're working on a few things. So we're hoping if we can crank through

36:37

our list of everything we want to get done this year, you know,

36:40

it should be should be on the lookout for that. So, yeah, we're excited.

36:43

I tried it. We're always we're always working on some thing.

36:47

I suck you into saying yes, because you said that before.

36:51

So so give us a little bit of a look of eventually.

36:55

What can you what can you let out of the bag that you're working on?

37:01

We publicly announced we're working with Valkyrie a

37:04

few months ago so we've always made Valkyrie Archery if you're familiar he's

37:07

based out west but always made Brent's Broadhead and things like that so we

37:13

are working with them on a couple new products for the coming year but yeah

37:18

and he yeah super excited about that partnership so I know a lot of people have

37:21

been asking questions so, yeah they they I mean they hit

37:25

the market strong it seems like we'll have answers for everybody buddy.

37:29

See you soon. Yeah. Alex, you're on a bad, bad delay. Sorry. She's breaking up. Yeah.

37:36

She's on a huge delay there. Yeah. I know that also while we're, we're catching up there with her,

37:42

you know, one part of the market that is, that I, I know listeners are going

37:47

to maybe stumble, hate me. I don't know, but I'm not a crossbow guy, but it's a no brainer that that market

37:54

is huge. Oh, absolutely. In every state where it's legal, goal there are more crossbow hunters than there

37:59

are vertical bow hunters every state so it only makes sense to jump into that

38:03

also so i'll just leave it at that right alex.

38:10

Yep i like how tight-lipped alex is if you need a secret cup she's a girl.

38:18

No no secrets so just it's just a matter of having.

38:25

Things going on and wanting to you know not over promise for the coming season yeah understood so,

38:34

give me top two heads right if

38:37

you guys if you guys are talking to a western hunter what are

38:40

the top two heads in the arsenal at vp

38:43

archery i mean i i would say if

38:46

you're looking at light and fast you can't go wrong with 100

38:49

125 grain three blade to me

38:52

you know you do get the extra that third blade you

38:55

know cutting surface there and then i could i

38:58

would never shy away from a single bevel or omega for anything

39:01

our regular single bevel the penetration that

39:04

we saw with that head before we switched over

39:07

to the omega actually a couple of my boys are still using the

39:10

single bevel i think we had one deer

39:13

that went over 70 yards with our

39:16

single bevel or omega mega and that was on a

39:19

poor head it was back a little far but i

39:22

will say that i believe that if it hadn't achieved the penetration

39:25

it did i think that the deer would have

39:28

been wounded we never would have recovered it instead he went to his first bed

39:31

unfortunately we had to wait till the next morning to recover him but he was

39:35

there and i know for a fact just from experience that if we hadn't gotten a

39:39

penetration out of that that deer would have been lost and that's sickening

39:44

anyone who has ever done it. It's just not a good feeling.

39:47

The worst. Yeah. So, you know, looking at, and I generally shoot 125 grain, right?

39:54

And I was looking at some of the, some of the three blade options and I'm going

39:58

to have to up my, my grain weight to move into that longer, that longer three blade.

40:05

I don't know. I don't know if it's an aesthetic thing or if it's my mind telling

40:09

me that, that longer blade option.

40:13

And design with the, you know, call it the 200s, the 250s, up to that 300 is

40:21

a better head than just a 125 three-blade. Yeah.

40:26

Yeah, with the three-to-one blade ratio, you know, the length and the diameter

40:30

kind of goes along with the Asprey Foundation's findings in their tests and

40:34

it's great for penetration. Penetration, but when you combine, you know, carbon or tool steel like ours,

40:40

whichever you're using, in fact, the carbon, the three-blade 100-grain, one of our customers is a high-volume

40:46

shop in the area, and one of their bow technicians this year tried our 100-grain

40:50

three-blade for the first time.

40:52

He sends me a picture, and he's in a saddle, and he's looking straight down,

40:56

and there's a buck laying at the base of his tree. And I said, did you shoot it? And he died under are

41:01

you and he said no i shot him straight down through the spine the

41:04

arrow came out and was touching the ground and he obviously just

41:07

dropped so blew completely through the spine went through the heart and the

41:11

buck dropped in his tracks that was with the three grain or the three blade

41:15

hunter grain which it's a small head but if you look at it too and you hold

41:19

it it almost to me just looks like a little powerhouse it's the first vpn head

41:23

i ever shot and it flew like a dart and And it just, it does some good work.

41:28

Yeah, that's the DRT is definitely the way to be.

41:33

I shot an axis last year and that was my shortest track ever.

41:37

And the blood trail was 11 inches long. I mean, you want to talk about stoked?

41:44

There ain't nothing like it. So I can't even imagine up in the tree,

41:49

the angle to come straight down on the spine like that.

41:53

Woof yeah and he was shooting a hinge that's

41:57

a stud right there yeah that's difficult he's he's

42:00

a good shooter he saw a shot competition so he's he knows

42:03

what he's doing obviously but that is a really tough shot at 10 not to mention

42:07

at a zero that's tough shot nuts so the okay so you talked about the regular

42:15

or premium single bevel so the difference in that from the omega is really the The sharpening,

42:20

maybe a little bit in terms of the shape and width of the blade.

42:27

Alex? Yep, yep. The sharpening is the biggest thing.

42:31

So you have to have a jig to sharpen the single bevel. The traditional single

42:34

bevel, I guess the ones you're looking at there on the screen.

42:37

We do offer the ones also in the carbon tool steel versus the S7.

42:42

So just different price points too, depending on if customers are looking for

42:47

a single bevel that's a little more affordable. They can go with the carbon dual steel option.

42:52

If they want to upgrade to that S7 steel, which is just a more premium,

42:55

it's going to hold that edge a lot better. They can get the S7 version.

42:58

So that's those guys. And then from there, we kind of applied those same design

43:02

characteristics a little bit.

43:05

When designing the Omega, just that easy lay flat sharpening technology there.

43:10

And then the Omega does have a tanto tip versus the chisel tip with a single

43:14

bevel. So we do get feedback from customers that like each.

43:17

We found them both to be successful with our testing. So we do offer both,

43:22

but everything kind of comes down to personal preference.

43:25

It seems like even though there's a lot of testing behind different heads,

43:28

people are always going to have their opinions on, you know,

43:30

what style they want and different things like that.

43:34

So I have, I want you to expand a little bit, expand a little bit between the,

43:39

the tool steel versus the S7, but to comment on what you said,

43:43

we all have our personal preferences. And I think the weight of that personal preference is derived 60 to 70 percent

43:51

solely based on aesthetics and not actual use or benefit of design.

43:59

I swear to goodness, I don't know why I say 60 to 70 percent,

44:03

but I watch people buy bows. I watch people buy broadheads. I watch people buy arrows and fletching and almost

44:10

everything is aesthetically based.

44:13

As much as we say, well, I like it's just dead in my hand, but you stared at

44:19

the color for 45 minutes and finally selected that one.

44:26

So that's my comment there. But if you can, for the folks that are listening,

44:30

talk a little bit about the differences in the tool steel versus the S7.

44:34

So they understand that that monetary difference in the value there.

44:40

Well, obviously, the Rockwell, the overall hardness is going to be different.

44:43

When you look at the application of S7 tool steel, I mean, they make fixtures

44:47

and dyes out of that stuff. So it's designed to be more durable.

44:51

With that, obviously, does come a cost. But we've also done some testing.

44:56

I also shot the S7 with a single bevel, but I did testing with the regular carbon.

45:01

As far as edge retention and all the testing I did, which would be bones at

45:06

home, even when I shot through a cow and deer scapula, as well as OSB,

45:11

I was really impressed with the carbon steel.

45:14

I mean, it's a great, great material. It's not like it's bad.

45:16

It's just S7 is just that extra step up there. So, you know,

45:21

the preference thing, like you'd mentioned, it is funny. I think what kind of intrigues people about a single bevel, or especially the

45:27

Omega, is the visual part. heart, it's like, what is this thing about?

45:32

Or, oh man, that's interesting. Even a single bevel, they go, why is it only sharpened on one side?

45:37

Some people don't understand what that does and what, you know, the science behind it.

45:41

And so you get to explain it. And then when you really think about it after

45:45

what you see it does to an animal, you know, and the amount of penetration you

45:49

get and damage and wound channel, it just makes a whole lot of sense.

45:53

But I would say the difference between the two like

45:56

alex said there's some preference for sure i mean

46:00

a harder material is a harder material it's still

46:02

okay to sharpen but you know if

46:05

you think about two the stuff that we hunted back in in the day like i

46:08

said they weren't anything like what we're making now and they held up pretty

46:11

well also i think personally the bottom line is if you think about if your bow

46:17

isn't tuned your arrow is coming out of your bow crooked oscillating it's not

46:23

doing doing what it's supposed to do, it's not impacting your target.

46:26

Perpendicular, straight, whatever that looks like based on the animal,

46:30

you're not only going to lose a lot of energy, but you're also putting undue

46:34

stress on the head itself. Instead of a nice, perfectly straight cut through the fur and the bone and the

46:42

tissue, you're not going to lose a lot of energy. You know, you go at an angle and you're just not, you're not making the best

46:48

use of that edge, I guess, is what I would say. It's only going to get more

46:51

dull as it goes through the animal. It can't get sharper. It can't. It's impossible.

46:57

And then the chisel versus the tanto tip.

47:01

I mean, that's, I mean, that's almost, that's almost as long a conversation

47:08

as single bevel versus double bevel.

47:12

Yeah i i would say out of

47:15

the tonneau tip obviously is a proven penetrator thing's

47:18

been around for a long time what i liked out

47:21

of the the um the tip on the single bevel

47:24

is it seemed to just displace bone

47:27

really well when it threw shoulder blade it just literally splits

47:30

it opens that up like twist it like it's

47:33

not even there obviously both work my omega worked

47:36

really really well this last year as well but again there's some

47:39

preference in it both are going to kill both are going to kill effectively i

47:43

just think that our heads i i call them boringly reliable

47:46

uh there's nothing to open there's nothing really fancy to look at it's just

47:51

a nice sharp quality piece of steel you put on the end of your arrow and it

47:56

does great work and that's kind of boring that boring is good though right i

48:01

mean yes ultimately right everything thing that we've talked about and, and,

48:05

you know, it all comes down to shot placement and time behind the string.

48:09

So boring, isn't a bad thing. Right. If you're putting it in the right spot, man, and build,

48:15

you know, for me, I love building arrows, right?

48:17

I try to build a, as good as an arrow as I could build, and then being able

48:22

to put something that's. Lack of a better word, fun, you know, and, and a little bit boring on the tip

48:29

and just go and have that consistency time and time again.

48:32

And that's one of the things that I said, you know, early on is when I pull

48:36

them out of the pack and I throw them on the scale, they're right there measure with,

48:40

I mean, and, and it's funny because you'll get, you know, you'll get from,

48:44

from tip to call it, you know, back of broadhead right at, you know,

48:47

where the ferrule is just full ferrule. And that's where I've seen more variance than not from company to company to company to company.

48:55

And okay, I only have a three pack, but to see how tight that tolerance was

49:01

on the Omegas, I was pretty impressed.

49:05

And then that grain weight falls in line, the accuracy from head to head in

49:09

that grain weight falls in line with where I want to be on my aero builds.

49:13

Now, when you guys go go through that is your is your

49:16

qa process before packaging are you

49:20

looking at grain weight consistency per pack or how does that look did we lose

49:25

alex i think we did and i think we did yeah our manufacturing process is kept

49:30

pretty tight-lipped i know they used to give tours through the shop and stop

49:33

doing that for different reasons including you know our ip it's important to maintain that.

49:39

But yeah, the quality that's maintained with blade thickness,

49:44

with weight, it's all pretty meticulous.

49:47

It's all very, very meticulous to make sure that nothing...

49:51

We don't want to sell a premium product that we call high quality and American-made

49:57

product and have an end user complain and say, hey, this isn't what you sold me.

50:01

That's just not good for business. It's not good for your name.

50:04

We have more integrity than that as a company.

50:07

And you know what i mentioned boringly reliable earlier too that's

50:10

what you said was perfect if you don't have to worry about

50:13

the weight the dimensions the blade thickness the

50:17

sharpness as long as you do your due diligence you put on the front of a an

50:20

arrow out of a tuned bow it is boring because you don't have to worry about

50:24

it that's right you tune your bow at the beginning is the hard part get that

50:27

done and get these things flying right but i'll tell you this much because Because

50:32

of the tolerance of these also, light issues you just don't have.

50:37

Now, is that to say you may not get some outlier maybe down the road?

50:41

But I personally haven't found any that wouldn't fly.

50:44

What I have found is if you insert tune them, you're going to get more variation

50:48

out of an insert, whether it's brass, aluminum, titanium, steel.

50:52

If you think about the diameter of an insert and your threads are off just a

50:56

little bit, just a little bit of angle, you're going to get run out in that head.

51:00

It doesn't mean your head's bad. And you have tolerance in the head,

51:02

tolerance in the insert, tolerance in the arrow.

51:05

So insert tuning is important also. If you get that thing to spin straight,

51:10

mark it, and then glue it in there, you'd have a lot better success as well.

51:14

I'm glad you brought that up, right? Because that's a very, very overlooked

51:18

point of an arrow build. And-

51:22

More times than not, the broadhead is blamed.

51:25

And it's the craziest thing. It's like you have an entire process there that

51:30

there should be checks and balances on. So I'm glad you brought that up. And that is part of my anal process.

51:37

You know, it's amazing. We've talked about it as a team and that,

51:41

you know, we spend $1,400 on a bow and we put high-end rest on and we put high-end

51:48

sites and we buy $300 releases.

51:51

I mean, we've got $2,500 in these packages, and then we go to Walmart and we

51:56

buy a three-pack of broadheads for $30. And to me, it's mind-blowing. I don't understand when that is the part of the

52:03

arrow, the most important. It's leading the way. The cutting edge.

52:07

That's the part that's going to make contact first, and it's going to help pull

52:11

that thing through the animal. And it's just mind-blowing to me that people take shortcuts on what I think

52:16

is the most important part of the bill. No, I would 110% agree with that.

52:21

I have a buddy that shoots that his bow has to be, has to be a dozen plus years old,

52:28

but he's smart enough to know that I'm going to go buy the best broadhead for my money that I can buy.

52:37

And every year he'll re-up six of them. He's like, look, I don't spend money on anything else.

52:41

I'm buying a new six of these, whatever they cost every single year.

52:45

And for as much guff as that guy gets about that bow, but you watch him shoot

52:50

it and he's lights fricking out, man. And he knows that's funny.

52:55

Yeah. Hey, I've got a Bowtech. I bought my first Bowtech back.

52:58

It was brand new. I bought it in 2003. I hunted with that for 16 years. I just retired that in 2019.

53:04

I couldn't deal with it. And actually, a funny thing is my wife was the one

53:08

going, what are you doing? Buy a new bow. Everybody else has one. I said, why?

53:13

It works. And then I went and shot some and I went, okay, there is a difference

53:18

in a 2003 model and modern bows.

53:21

Massive difference in efficiency and and features and tunability it's not even

53:26

close so since then i've probably bought 15 or 16 i just got this this thing

53:35

here it's in a lift yeah man yeah it's i mean unreal,

53:43

unreal and guess why i settled on it i love the way it shoots but it has the

53:49

masio land the color got me. Alex knows. 45 minutes. There it is right there. He stared at it and said, I love the color.

54:02

It's so freaking cool too. And it's that old bottom land.

54:05

Oh man. Those bows shoot really nice. My youngest son has one on order.

54:10

I ordered it in late December. It'll be here in mid-May.

54:13

So I can't shoot those. The Matthews, I've got a from sports,

54:17

I've got a kind of a messed up left thumb and the way that riser

54:21

shape i cannot get my thumb out of

54:23

the way and it just wears a hole in it it's like it's debilitating

54:27

and it's too bad because i just shot one of those again today they're a

54:30

really nice shooting bow i was super nice i haven't shot

54:33

a matthews in five or six years i mean shot them but you know haven't owned

54:38

one or purchased one and i shot this bow at expo and i tried to buy it from

54:44

matthews right there i was like okay where do i sign in that and and luckily

54:49

you know why well not local They're a few hours away, but no limits.

54:53

Took care of me and said hey we got a bottom land in and i ran i ran the two

54:57

and a half three hours over the hill to go pick it up saturday i mean just a

55:02

wonderful shooting bow and and the the.

55:06

Meticulous efforts that they put into their r&d to

55:09

really get everything dialed in from the limbs to the string and and really

55:14

said hey we got to look at this entire package and not just a new new riser

55:19

or a new cam so it's really really really a well balanced great shooting machine,

55:27

right yeah it'll look nice with the uh omegas flying out of that thing well we'll see this week,

55:34

actually can't shoot that one yet because i don't have my sight on it but,

55:37

we'll get a site i'm waiting on that site to come in i'm hope i'm

55:40

hoping all i need is about four or five hours at the range before texas and

55:45

i'm good so we'll see what happens but the omegas they got they got spun on

55:51

some arrows last night and i was hoping to shoot them today but we'll get out

55:54

tomorrow and send some downrange and typically that hunt we're shooting,

56:01

under sub 65 ish there's a couple stands where the pigs will come down the roads

56:08

and they'll offer you a little bit of a further shot i think the last pig i

56:13

took out of there i think was like like 62 yards from a stand.

56:18

So we'll, we'll get to have some fun, but you definitely got to have the night

56:22

at locks in that scrub country down.

56:26

So forward to it. So before we wrap, let's tell folks, you know,

56:31

where they can get ahold of you guys, what the website is, YouTube,

56:35

et cetera, et cetera, et cetera. Alex, you go ahead.

56:39

Did we lose her again? I think she's just here for the giggles at this point.

56:42

All right. all right i'll get it started and if she she gets her connection back,

56:49

vparchery.com i'm here you guys are the

56:52

ones who are lost alex are you sure all right i'm good there's yeah go ahead

56:59

now tell us where they can find us you can find us at vparchery.com just google

57:04

vpa vantage point archery we're on all the social media platforms so give us a follow They're yeah,

57:10

really anywhere you can find us and we'll post about new products and different

57:14

deals we have going on and different things like that. So be sure to reach out with any questions.

57:18

And then the YouTube is the same VP archery. Yep. Yep.

57:23

And any last words, give me, give, give the folks the elevator pitch on why

57:29

they should open that website right now and get some VP archery points screwed

57:36

onto those arrows this season. You want to go first, Alice? Sure. If I don't get kicked off here.

57:42

Yep. Precision machined, American made. So solid one piece construction,

57:46

no metal injection molding, no welding together.

57:50

So super durable, lifetime warranty.

57:53

So say you had past throw hit a pile of rocks, you can't sharpen it out.

57:56

Send it back to us. We'll send you to replace my head. Yep.

58:02

So there's that. There's the business aspect. I would just say,

58:05

looking at it from my perspective, kind of fortunate with long arms and I'm pretty tall.

58:10

So I have a long draw length, 31 and a half inches, generate a lot of energy.

58:15

So I could probably shoot a lot in different heads. But I would also say that

58:19

because of the energy that is generated out of my draw length,

58:22

the fact that we pass through, we're sticking in the ground afterward and the

58:26

edge retention is still there, I think speaks volumes.

58:29

Volumes and i would also say if you were a shorter draw

58:32

person don't shy away from fixed blades

58:35

that is more important in my opinion you

58:38

don't want to you don't want to give away energy giving away

58:41

energy to open a mechanical is just it just

58:44

doesn't make any sense i can't imagine a nascar driver saying hey

58:47

we can top out at 700 horsepower for race

58:50

a but let's go to 650 instead it just

58:53

doesn't make any sense so maximize your

58:56

potential and do that with a fixed blade head especially if you

58:59

have a short of draw length or you're down on draw weight a little bit

59:02

thank you well i appreciate the time

59:05

greatly i look forward to sending these down range this week and sending you

59:10

guys some pictures hopefully a couple more access and some piggies down there

59:14

in texas everybody if you're listening go check them out at vantage point archery

59:18

give them a follow on instagram and go sub over at youtube,

59:24

thanks guy we appreciate it thank you guys.

59:29

Music.

From The Podcast

Western Contours

Western hunting is as diverse as it gets from pursuing coastal Blacktails or pigs in central California, Antelope on the open plains of Wyoming, Roosevelts in the western units of Oregon or chasing bugles in a drainage somewhere in Colorado. The opportunities, game and landscapes offer a multitude of possibilities to all bold enough to challenge themselves to adventure past their comfort zone.Whether it is to carry on a tradition passed down through generations, or those looking to answer a curiosity or a primal calling, adventure seekers, field to plate providers or the skilled woodsman or woman. The only thing that offers more diversity than the west are the people who have accepted this challenge. Though we have common goals our paths are as diverse as the land we put boots on or the game we pursue. Through trial and tribulation, self reflection and perseverance our stories come together. A community of like minded individuals who’s pursuit of game is through ethical take and responsible use of the land we tread. Western Contours podcast sharing experiences and providing insight to make us all better hunters.Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

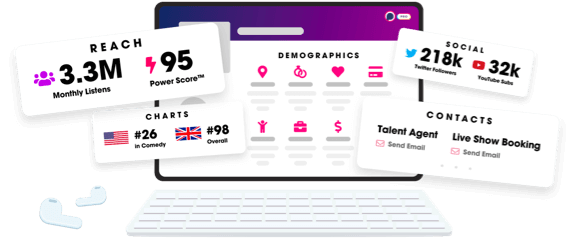

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us