Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:02

Rob Segal: The last bit is, outside of AI, everyone's next favorite topic is digital twins.

0:07

And I've been playing with this idea of, is your digital twin identical or fraternal?

0:13

So today everyone assumes it's identical, right?

0:16

I have built a model, a representation, a flow chart of how my system works.

0:20

But until you start tracking how it actually operates, you don't know how accurate it is.

0:26

It's one of the great things about our solution is that you can then see how accurate and how close to the ' as designed' are we?

0:32

The 'as designed' is the ideal world version of how we think it should operate.

0:38

But it's the 'as built' is it actually working the way that it needs to?

0:44

Richard Howells: Welcome to the Future of Supply Chain podcast. My name is Richard Howells.

0:47

I'm a Vice President for Thought Leadership for SAP's ERP, Finance and Supply Chain solutions.

0:51

And I'm joined by my wonderful co-host, Nicole.

0:57

Nicole Smythe: Hi everyone. I'm Nicole Smythe, and I'm a blogger, marketer, and podcaster in the supply chain space here at SAP.

1:05

So today we're joined by Kinexon's Rob Segal to dive into the importance of data and visibility in transforming a company's ability to make decisions.

1:15

So to kick us off, Rob, could you just take a quick moment to introduce yourself and give a little insight into what you do?

1:22

Rob Segal: Sure. Richard, Nicole, thank you so much for having me.

1:25

It's a pleasure to be here today. So as you said, my name is Rob Segal.

1:29

I'm the Vice President of Sales for Industrial IoT at Kinexon.

1:32

We are a technology company based in Munich with US headquarters in Chicago.

1:37

I personally have been in the engineering simulation space for more than 20 years now, slowly moving closer and closer to supply chain, fromdesigning embedded systems for controllers and wireless systems to simulating physical components with computer aided engineering software.

1:53

And now I'm much closer by helping people automate and track movable objects and assets on the manufacturing floor.

2:02

Richard Howells: Okay, so let's start with a high level question.

2:04

What are some of the challenges that the supply chain executives you're working with are seeing in the field?

2:10

And what do they think they need to address these challenges?

2:14

Rob Segal: So, there are two main challenges that I would like to highlight: first, there's this huge untapped potential in further connecting and automating operations on the shop floor.

2:24

The majority of assets on the shop floor are movable and not typically connected; a lot of the focus in the last few years has really been on OEE and getting maximum output from our fixed assets.

2:37

But this all creates a reliance on manual tracking, which is error prone and inefficient, and this, in turn, leaves a blind spot for organization.

2:45

It also means that we rely on humans to do repetitive, non creative tasks that we're just not that good at.

2:51

And it's hard to make good business decisions if you don't have an accurate picture of what's happening.

2:56

So part of what we want to help people do is instrument the moveable assets on the shop floor so they can have a better understanding of what's going on so they can make better decisions.

3:07

Secondly, organizations are facing increasingly complex tech stacks that include siloed solutions.

3:14

This is true with our real time location systems.

3:17

That's our system to allow people to keep track of assets as they move around, and we see these silos based on the technology they use - whether it's ultra wideband, RFID, or even GPS.

3:28

It's even more prevalent when we think about fleet management for autonomous ground vehicles and autonomous robots inside of facilities.

3:35

Most of the manufacturers of that equipment actually make their own fleet management solutions.

3:40

Now this creates this scenario where people have to either choose one vendor and the hardware itself may not solve all of the problems they want to solvefor, or they have to choose multiple vendors that now have multiple fleet managers that your IT team has to manage and integrate into larger ecosystems.

3:58

So finding software that has agnostic to hardware solutions allows our customers to have optionality to choose the right Operational technology to solve the problem at hand.

4:10

Nicole Smythe: That's great. And to be able to have that optionality, like you said, is incredible because I think a lot of the times companies may feel as though they have to invest inso many different types of technologies to be able to solve the problems at hand, but to be able to have hardware that covers all of the bases is really great.

4:29

And Rob, you mentioned data visibility as one of the main focus points that companies and executives need to be able to address those hurdles or those challenges that they're facing.

4:39

But as we all know, we can't measure on averages, we need the actuals.

4:44

So with that, what are some of the ways that data can be leveraged in a supply chain, especially in a production and logistics setting?

4:52

And of course, on top of that, what are some of the innovative ways that it's being leveraged versus just simply having Excel files?

5:00

Rob Segal: Oh, it hurts my heart when I hear people talk about using Excel files.

5:04

I've come from a world where that has been our biggest competitor, Excel is the number one tool used, but that's not what it's really meant for.

5:10

And that's true in all phases of organizations that Excel becomes our default, but I digress.

5:16

To me, what we're really asking here is about automation and AI, and those things aren't possible in a really productive sense without having clean, accurate, and up to date data.

5:25

Working off Excel inherently means you're using manually entered data that's not easy to create automation from.

5:31

For example, I was talking with one of my customers and he said to me, he did a test of manually tracked assets on the shop floor versus using a real time location system, RTLS.

5:42

The manually tracked assets were less than 60% accurate in terms of where they were based on the ERP.

5:48

When they used an RTLS system, they were 98% accurate.

5:52

Now, they're only 98% because someone took a tag and went home with it.

5:56

So we still can't fix all of human engagement, but this is the highlights how the automatic logging, tracking of events and assets on a shop floor mean to get clean and accurate data.

6:09

In a practical sense, allows for automation.

6:12

So RTLS automating bookings during the assembly process.

6:16

So as work in progress moves from one cell to the next, rather than having somebody manually key in that it has been completed and moved on tothe next cell, allow the movement and its location to automatically say back to the MES and ERP, this is what has been done and where it is today.

6:34

This just gives a greater real time visibility into the production process and allows you to highlight bottlenecks and delays before deadlines are missed.

6:42

Manually tracking on whiteboards doesn't really allow for up to date communication.

6:46

When I go into a factory and they tell me that the way they communicate their challenges back to management is by having them come down once a day to the shop floor and look at a whiteboard, it gives me shivers.

6:58

The reality is that data is accurate enough so that nobody gets in trouble and maybe to highlight a few critical errors.

7:06

But it's not always completely accurate, and it's not up to date, and it's not real time.

7:12

Nicole Smythe: Absolutely. And I've had the pleasure to be able to see that in real time in our own Newtown square industry 4.0 Innovation Center, which is just amazing.

7:22

And of course, Rob, that's where we met.

7:26

And it's a great asset in our relationship between Kinexon and SAP here, with different products and solutions working seamlessly together.

7:35

So can you dive a little bit into our partnership here and also talk about really what people can expect when they not only visit the Factory, but what they can see with our two companies working together in the sense.

7:47

Rob Segal: Yeah, sure. We're really honored and proud to be a part of the Industry 4.0 Innovation Center in Newtown Square.

7:53

It is an amazing demonstration of SAP's ability to solve for the modern challenges of manufacturing facilities and the ecosystem around them.

8:02

So in the facility today, Kinexon's real time location system is set up, and our fleet management tools as well, to help people understand how they can track assets as they move fromone part of the manufacturing assembly process to the next, automating that booking process back into the ERP, seeing what's happening, moving the AGVs from one location to the next.

8:23

So, for instance, as they start the process of saying we want to start working on this valve, this work in progress, they can send that order through EWM andWarehouse Robotics, off the fleet manager, it will bring the parts to the first assembly cell where it's been tracked because it has a Kinexon X tag on it.

8:41

You can see that it's there and it logs with there, it started the assembly process now.

8:45

And as it moves from one cell to the next, you can see it in action, not just how our system is tracking it, but how that data is pushed back into SAP.

8:53

To me, this highlights the partnership and why our organizations are working together.

8:58

It's not about just tracking. That is one component of the assembly and production process.

9:04

It's about having a holistic view of what's going on.

9:07

And that's where SAP becomes critical to our customer success.

9:12

We want that ERP system to be the system of record.

9:15

I think you all would agree with that, correct? And so what we're allowing our customers to do is to automate the process of making their ERP a highly accurate system of record.

9:26

Richard Howells: I want to change tracks a little bit to an equally important question, in my mind, because I am a huge soccer fan and to prove that I'm bilingual in American and English, football for those Europeans watching or listening.

9:42

And I was in Munich a few weeks ago, and some of your executives tried to relate it to everybody in the audience and gave a sports example, because I believe that KinexonSports is being used to track the movement of the soccer balls in the upcoming European Championships in Germany to see whether a ball goes out of bounds or over the goal line.

10:02

So can you tell us a little bit more about that?

10:05

Because I'm intrigued by that one. Rob Segal: Yeah.

10:08

So Richard, to me, when people ask me about the sports side of Kinexon, I always say that's the more fun part of what we do.

10:14

I love the industrial part of the business, but I also love sports.

10:17

And like you, I love football as well. I'm more of an Arsenal man myself than any of the European National Team.

10:23

But I'm still excited about our support of the European Championship this summer.

10:26

So you are correct. We're partnered with Adidas this summer for the European Championship, as we were for the last two World Cups, to have a sensor inside of the ball.

10:34

It's been used to keep track of where the ball is in play, but in practice scenarios, we also help track athletes, as well.

10:40

Just like on the factory floor, understanding where movable assets are at any given time, allow you to see what's happening, a more complete and holistic picture of the field of play.

10:53

So I've read a couple of books about soccer theory and strategies, and they talk about creating and destroying space, and that movement, that hidden movement, is one of the things that makes soccer players really amazing at what they do.

11:06

And Kinexon can help people understand how athletes are moving into that space and moving back out of it.

11:11

Now, again, not dissimilar from an industrial application in that we're still tracking high valued assets.

11:17

That movement, off the ball, as you move WIP throughout the process, that's what makes organizations really good at what they do.

11:25

For instance, I was talking with a customer recently and they said they found that one of their components, as it was being produced, was actually traveling 30% further than they thought it was and as it was modeled.

11:37

Now I heard that and I thought, okay, it's a few feet, a few yards, a few meters, for our European friends.

11:43

It turns out that specific product was moving 18 kilometers, which is 30% more than it's supposed to.

11:50

That's an enormous amount of waste.

11:52

And so being able to see how athletes, how assembly processes are operating, allows you to understand where there is waste and how you can create efficiencies.

12:03

Richard Howells: That was a great example. And I'm sure you could use exactly the same example if you had a tracker on somebody on the shop floor or in the warehouse to see if they're optimizing their routes around the warehouse, as well.

12:15

And I wanted to bring it back to the business context as well, because that was a great example of location based tracking.

12:21

And the tracking of the extra movement is a great example of how you could improve sustainability because you're using less energy if you move the vehicles around less.

12:30

But, how is this location based tracking and movement tracking being leveraged in a business context, especially when we talk manufacturing and logistics?

12:39

Rob Segal: Sure. So there are two examples that I love.

12:42

One of them is an automotive OEM that actually has our sensors set up above their assembly line.

12:47

So, as a chassis moves down the assembly process, there's roughly 300 different cells that that individual car has to go through.

12:55

On a manual line, at each one of those cells, a person will take a barcode scanner and scan the paper traveler, just taped to the hood of the car.

13:05

Now, when I first started talking to this customer about it, they said, it takes two and a half seconds.

13:09

And I thought again, like the 30%, two and a half seconds, who cares if we save you two and a half seconds?

13:15

And he said, but if you're talking about 300 to 400 cells and a thousand cars per day, that can really matter.

13:22

So the number he gave me, and I haven't actually done the math on it, but he said that saves up to 80 hours per day of work time.

13:29

Richard Howells: Wow, so literally every second counts in that example.

13:32

Rob Segal: Correct. Exactly. So, when you have assembly processes that have tighter margins, like automotive, is trying to squeeze out efficiency from it, saving those seconds really matters.

13:42

On the other end of the spectrum, if we think about an aerospace example, MRO, for example, if a part comes in for repair, almost bydefinition, it's nonstandard because each part needs a slightly different amount of care, some different processes is going to be applied to it.

13:55

And so being able to move that part through your MRO facility, and because it's tagged, and you know which part it is, and which work instructions are assigned to it, ateach cell, the appropriate work instructions can be assigned to that operator, and they can be brought up through DM, SAP's DM, to see what should I be doing to it right now.

14:16

This is one of the powers of understanding how location based technology can make workers more efficient and eliminate manual errors.

14:23

Richard Howells: That really optimizes the process then because, based on what's coming, if you can get what you need in front of you before it arrives or as itarrives, you'd be searching for paperwork otherwise, or going through different screens looking for the tab you need to be on, and I know how long that can take.

14:38

Rob Segal: Or the worst case scenario is that you actually use the wrong work instructions and you ruin a part.

14:44

Richard Howells: Yeah. Nicole Smythe: No, absolutely. And I just want to give a quick shout out.

14:48

I really appreciate the metaphor that you made between sports, you know, Kinexon Sports and also supply chain.

14:54

Being a former athlete and also supply chain degree in college, it really has a special place in my heart, so I appreciated that.

15:02

But, we've talked about so many different things today - data visibility, real time location, having the analytics right at your fingertipsin real time - and I think all of our listeners have already been getting so much valuable information from what we've been talking about.

15:18

But on top of that, are there any other topics or questions that you feel are top of mind that you'd like to continue to share to our listeners so that they can really take it home with them as they listen to this episode?

15:31

Rob Segal: Yeah. So I think I want to highlight a couple of the things we've already talked about and then bring up one additional one.

15:36

So, first of all, as I've been talking to people around the SAP ecosystem and Kinexon's customers and partners, what I've come to find is that people often are looking for the bandaid to put on the wound.

15:47

And so I was talking with a partner who we typically think about indoor logistics, indoor location tracking.

15:54

We talked to a partner who was talking about outdoor tracking, so GPS stuff, really a logistic solution.

15:59

And he said how do we get our software to talk to each other so we don't have to worry about an ERP?

16:04

And immediately I said, but that's what it's there for.

16:08

So again, I said it earlier and I'll say it again, that allowing SAP S/4 to be the system of record, to push that data back to where it's meant to be, Enterprise Resource Planning, it's in the name of the solution itself, let it be that.

16:23

And so this is where I think Kinexon can really add value to SAP customers is not in replicating work that's already done by you all or necessarily just automating tasks.

16:32

There's certainly value in that. But it's about getting more value out of the systems they have spent time and money putting into place so they can make good business decisions.

16:42

So if we get real time, clean, accurate data into that ERP, it gives people that opportunity to really think about - are we making good business decisions?

16:51

They get a clear lens into how the system is working today.

16:55

The second thing I would be remiss not to mention is artificial intelligence.

16:59

Everyone wants to talk about AI. And I get this question constantly.

17:03

I had someone call me yesterday about it. And I said how do we fit into AI?

17:08

And the thing that today I think we do really well is create a good, clean data set for training.

17:15

So AI can't really do anything for you if you don't train it on accurate data.

17:21

You'll get bad results, garbage in - garbage out.

17:23

So by automatically tracking an object as they move around a shop floor, by understanding how people are moving around, WIP ismoving around, AMRs and AGVs are moving around on the shop floor, now you can get your baseline of what's actually happening.

17:37

Now you can train it to go out and find creative ways to build solutions that are more efficient.

17:43

This is, I think, in today's world, isn't necessarily the future, but today, this is the way that we can really play with AIs by creating that training set.

17:52

The last bit is, outside of AI, everyone's next favorite topic is digital twins.

17:58

And I've been playing with this idea of, is your digital twin identical or fraternal?

18:03

So today everyone assumes it's identical, right?

18:06

I have built a model, a representation, a flow chart of how my system works.

18:11

I've got it inside of Visio, I have it on PowerPoint, look at it.

18:14

It's a digital twin. Even if you build it in Kinexon software, it's a digital twin.

18:19

But until you start tracking how it actually operates, you don't know how accurate it is.

18:25

It's one of the great things about our solution is that not only do we have the tracking ability, and the process modeling, but the process mining, so you can then see how accurate and how close to the ' as designed' are we?

18:37

So when I came from the world of manufacturing, computer data engineering, building components, we talked a lot about the 'as designed' versus the 'as built' and the digital twin is the same thing to me.

18:49

The 'as designed' is the ideal world version of how we think it should operate.

18:55

But it's the 'as built' is it actually working the way that it needs to?

18:58

And so using a tool like Kinexon to look at it and say, are we close or not, gives you the ability to then understand, is our digital twin identical or fraternal?

19:08

Nicole Smythe: I love that. I think you have to patent that.

19:10

So if in five years or so, if that's not patented by then, we absolutely have to make sure we circle back and make sure that you do.

19:18

But Rob, we've had such a great conversation so far.

19:22

So we've talked about the challenges. We've talked about overcoming those challenges.

19:26

You know, the role of real time data visibility in making those decisions.

19:31

But one thing, of course, as we wrap up that I'd like to touch on is how Kinexon can help companies integrate and innovate moving forward.

19:40

So how can Kinexon help our customers and anyone that's looking to work with you and your company?

19:46

Rob Segal: Yeah, so there are two main themes in how can Kinexon help, in my opinion.

19:51

Number one is change management, right? So we just talked about the idea of digital twin, and is ' as built' the same as the 'as designed'?

19:58

But change management comes from now we can see there's a problem, right?

20:02

But in order to see that problem, you have to instrument it.

20:04

You have to measure it. You measure what matters, right?

20:06

Now you start to understand... how is it working? Where is the root cause of the challenges we have today?

20:11

Phase one of change management is unsticking people from the mode they're in today, and then you start to change and look for small wins.

20:17

Again, if you don't know what you need to change, you can't start to change it.

20:21

And once you start to change it, you need to monitor that change so you can ensure that you're actually getting the results that you intended to get.

20:28

And because you can then monitor those small changes, now you can celebrate the small wins.

20:33

Hey, this month, we've delivered 98 instead of 96% of our deliveries on time, on schedule.

20:40

That's a small win, but it matters to celebrate those victories.

20:43

Richard Howells: It's like that two seconds... that two percent is huge as far as volume and revenue and customer satisfaction is concerned.

20:51

Rob Segal: Absolutely. I have a former colleague of mine who's at a large semiconductor company now, and he said, if you told one of our executives, you can save us 0.1% through efficiency, everyone gets out of bed and they'll come talk to you that day.

21:06

Those little percentages matter when you start talking about large scale manufacturing processes or high valued assets.

21:13

I met someone last year at the assembly show who told me that each thing they were building cost over a $100,000.

21:20

And he said, because of security reasons, he couldn't tell me what it was, but each one was over $100,000.

21:25

So any delay in that delivery was extremely expensive for them.

21:29

So the focus is on how can we do things on time?

21:31

Let's go eek out those levels of efficiency. Let's make people a little bit better.

21:35

The other thing I want to talk about, I mentioned it earlier, is the notion of having software that's hardware agnostic.

21:40

This is my new favorite word is optionality.

21:43

So allowing our customers to choose the right operational technology for the problems they have today.

21:48

If you think about AGVs and AMRs, autonomous robots on the shop floor, different vendors offer different solutions.

21:55

Some are good for moving large, heavy objects.

21:57

Some are good for quickly moving smaller, lighter objects.

22:02

No one vendor is good for every potential use case on a shop floor.

22:07

By allowing them to use a hardware agnostic fleet management solution, we give them the ability, the power to solve problems in the most efficient way.

22:17

And we eliminate complexity and risk in the IT side of the house because they only have one fleet management tool to work with, and they have greater visibility intoit - fewer integrations, less vendors to deal with, and suddenly everything's in one place, and they can get a holistic view of the shop floor as technology is moving around.

22:34

Richard Howells: Rob, we're coming to the end of the podcast and I have to say don't let any of your sports colleagues put you down because you are working on the cool stuff, without any doubt.

22:44

So if you've listened to the podcast before, you'll know what's coming next.

22:47

And if you don't listen to the podcast, you're in trouble.

22:50

Because I'm going to ask you the million dollar question.

22:53

So if you could in a sentence or two, what is the future of supply chain?

22:58

Rob Segal: That's a big question to answer in just one or two sentences.

23:01

But from mine and Kinexon's perspective, the future of supply chain entails greater visibility in real time and automation of repetitive tasks.

23:11

This creates greater resiliency and adaptability for organizations.

23:16

Richard Howells: That is concise and perfect. And I think we've said this a lot in the podcast that the answer usually comes back to improve visibility.

23:24

If I want to get better insights, if I want to reduce the risk, if I want to improve sustainability, I can't do it without visibility.

23:32

And you said somewhere in the middle about you can't manage what you can't measure or something to that effect.

23:37

You have to have the data. It's gotta be accurate data.

23:39

So that summary was perfect. Thanks for joining the series and thanks for a great conversation.

23:44

It's been really interesting. Rob Segal: It was wonderful to join you all.

23:46

Thank you both for having me. Richard Howells: And thanks everyone for listening.

23:50

Please mark us as a favorite. You can get regular updates and information about future episodes.

23:55

And also please join us at the upcoming Sapphire and ASUG conference on June the 4th and 5th in Orlando, where the importance of a company's supply chain will, yet again, be a major focus of interest.

24:06

But until next time from Rob, Nicole, and I, thank you for discussing the Future of Supply Chain.

From The Podcast

The Future of Supply Chain

The Future of Supply Chain podcast is a show hosted by Richard Howells, Sin To, and Nicole Smythe. The trio discusses hot topics, best practices, and the latest innovations to deliver a risk-resilient and sustainable supply chain. The show features interviews with experts from the world of supply chain, sustainability, and Industry 4.0, who will address the issues of today and tomorrow. This is an ideal podcast for supply chain, R&D, manufacturing, logistics, and operations executives to learn and share ideas and best practices with their peers.Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

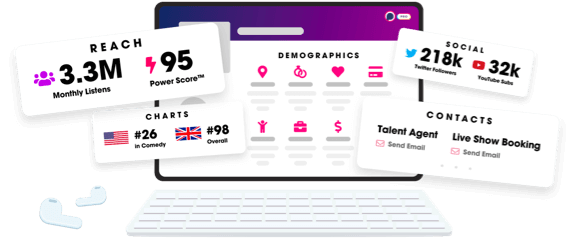

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us