Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:01

Sunita Suryanarayan: So, the future of supply chain is going to shift towards a more localized, reconfigurable, and decarbonized value chain.

0:09

What I mean by that is the future of supply chain will focus on reducing carbon footprint, adapting to local market demands, and enhancing flexibility in response to dynamic conditions.

0:23

Advanced technologies like IoT and Generative AI will drive automation, visibility, and data-driven decision making will play a key role in shaping the future of resilient and sustainable supply chains.

0:38

Richard Howells: Welcome to the Future of Supply Chain podcast.

0:41

My name is Richard Howells. I'm a Vice President for Thought Leadership for SAP's ERP, Finance, and Supply Chain Solutions.

0:48

And I'm joined by my wonderful co-host, Nicole.

0:51

Nicole Smythe: Hi everyone. I'm Nicole Smythe, and I'm a blogger, marketer, and podcaster in the supply chain space here at SAP.

0:59

So today we're in store for a great conversation as we discuss Accenture's recent study, Resilience in the Making.

1:06

And, to do so, we're joined by our guest, Sunita Suryanarayan from Accenture.

1:12

So Sunita, could you take a quick moment to introduce yourself and give a little insight into what you do today?

1:19

Sunita Suryanarayan: Absolutely. Thank you so much, Richard and Nicole.

1:22

Nice to meet you. I'm so excited to be here today.

1:26

I'm Sunita Suryanarayan, a Managing Director at Accenture within the Strategy and Consulting practice.

1:32

I have over two decades of consultative experience with C-suites and boards, working through a variety of risk management domains, including enterprise risk, supply chain resilience, third party risk and ESG reporting.

1:45

I've also led several digital risk transformations within high tech, automotive, and consumer product industries.

1:51

In my current role at Accenture, I lead supply chain resiliency for North America and work extensively with MIT and leading high tech organizations to bring predictive and prescriptive supply chain resilience solutions to my clients.

2:06

Richard Howells: So, , Sunita, risk resiliency has been the phrase on everyone's lips in the last few years and to set the stagefor our listeners, let's dive into a little bit about the Resilience In Making research that you conducted with your colleagues.

2:20

What did it entail? Who were the people that you interviewed?

2:24

And what was the scope of the research? Sunita Suryanarayan: Sure.

2:27

So, as you mentioned Richard, resilience and risk has been on everyone's mind.

2:34

Unforeseen disruptions have surged in recent years, not just from geopolitical shifts and extreme weather, but also technology breakthroughs and shortages of material and talent.

2:45

Few businesses have sustained their resilience and long term growth amidst this turbulence.

2:52

So, with our research, we sought to understand, more specifically, on how our clients manage disruption within engineering, manufacturing, and supply chain.

3:03

Specifically, we were asking the following questions: are they investing in the right capabilities?

3:08

Are they utilizing these capabilities at their disposal?

3:12

And are they fully unlocking the potential to gain a competitive advantage?

3:17

In other words, what are they doing to build more resiliency?

3:21

But before we get there, let's talk first about what do we mean by resilience.

3:26

For us, resiliency is broadly defined as a company's ability to proactively sense, absorb, adapt to, and recover from disruptions.

3:36

A company that is more resilient can produce goods, deliver services, meet and increase customer demand, and respond to changes faster than all of its competitors.

3:47

Just a few points and evidence - in the past couple of years, businesses have reported a 40% increase in product order-to-deliverylead times, and a staggering 1.6 trillion in revenue growth opportunity that was missed out on each year due to disruptions.

4:06

As part of our research, we developed a framework of 31 resilience capabilities to measure an organization's maturity across severalcategories including, demand foresight, autonomous production, agile workforce, smart end-to-end control towers, digital twins, and the like.

4:26

We surveyed over 1,200 senior executives across engineering, production, supply chain, and ops, all from businesses with an average turnover of 23 billion.

4:38

The respondents were represented over 11 industries, and 14 different countries, across multi-regions, we included the Americas, EMEA, and Asia Pacific.

4:48

All of these 1,200 senior executives were assessed in their strategies for sourcing and manufacturing, responsiveness to disruptions, and investments they were making towards resilience.

5:00

Nicole Smythe: Well, Sunita, that's incredible. And the questions that you've asked to the field are some great questions, and the topics are certainly top of mind, like you said, for executives across all different industries, countries and regions.

5:13

I think the best part about is that there's really going to be diversity within the research, as well.

5:17

So you're really seeing a lot of different viewpoints and key findings.

5:21

So from that, what are some of the key findings from the research that you've all found?

5:27

Sunita Suryanarayan: Thank you, Nicole. Before I get into the detailed findings, what I will say is that of the 1200 some executives we interviewed, we saw a clear mindset shift at the C-level.

5:41

Leaders are now recognizing that building resiliency is no longer an option, but a necessity.

5:48

And operation executives often have two competing priorities: the need to run with increased efficiency, but also the need to recover quickly from a disruption.

5:58

The good news here is that both technology and resilience capabilities have advanced, where organizations feel that they can achieve both priorities without compromising the other.

6:11

So at an overall level, we found that 97% of the executives plan on significant improvements in their supply chain and manufacturingcapabilities, and they're increasing their investments in facility relocations, automation and digitization by 34% over the three years.

6:29

But let's break it down into more basics, right?

6:33

When we think of a key indicator of a company's overall resiliency, we look at the speed at which companies react, respond and recover from disruptions.

6:43

And what we found from our respondents that the average time for being alerted of a disruption to staging a recovery is three months, and for some of the slower Moving companies that can even reach five months.

6:58

For 57% of the companies, it takes a week or more just to be alerted to a production or a supply network disruption.

7:07

And then 80% from there, it takes a week or more just to assess the disruption's impact.

7:13

That is two weeks lost before they even do anything about it.

7:17

Only 16% have a digital cockpit that even enables real-time visibility to understand what disruptions might be coming their way.

7:25

So when we look at this overall, very few companies consider themselves mature, in terms of having a resilient operation.

7:33

And they all exhibited a maturity score of 56, on average on a scale of 100 across all the 31 capabilities that I talked about in the framework earlier.

7:43

When we think of establishing resilience, it requires an enterprise wide strategy to set the stage for a complete transformative change across the organization.

7:54

Companies who wish to unlock this value need to prioritize their investments in 11 emerging capabilities.

8:03

These are what we call the Resilience 2.0 capabilities, which were more aligned to better resiliency outcomes.

8:10

Powered by data, digital, and AI, these capabilities enable the organizations to make broad changes, from employee and customer experiences to sustainability, all while increasing revenue and reducing costs.

8:25

For example, dynamic and sustainable product development capabilities, which is one of the core emerging capabilities in Resilience 2.0, enables businesses to reach their customers faster,moving them from ideation to production, to go to market at an accelerated pace, while making it easier for engineers to design more relevant, sustainable, and differentiated products.

8:49

Another key insight into the findings is that production and supply chain networks are de-risking by multi-sourcing and producing across multiple sites, shifting more away from globalization towards regionalization.

9:04

Sole sourcing is dying. Respondents have indicated that the practice of sole sourcing strategic commodities in the next three years will reduce.

9:15

It will rise from 42% today to 72% making more use of multi sourcing.

9:21

Proximity to customers is also paramount - 65% of the companies intend to buy most key items from regional suppliers by 2026.

9:32

It's up from 38% today. Even more organizations plan to produce and sell most of their products in the same region by 2026, almost doubling from 43%.

9:46

Fewer dependencies on global suppliers and plans means fewer single points of failure, which increase resiliency disruption.

9:55

With regional sourcing and production, companies can deliver products faster with a lower carbon footprint and respond quicker to new buying patterns.

10:06

Final insight - investments are growing.

10:08

The average investment in resilience, relocating, automating, digitization was approximately 1 billion, with almost half of that coming from reshoring based on our survey results.

10:21

Richard Howells: That's some amazing results and it's great to hear that Resilience 2.0 companies are doing exactly what we've been talking about in this series for the past year or more, things like multi sourcing, regional production, et cetera.

10:35

We've been talking about the right things and it's being proven by this research, which is great news.

10:40

But what did the research show about the benefits achieved by a resilient company, those companies that are deploying Resiliency 2.0 capabilities?

10:50

Sunita Suryanarayan: So what we are seeing with Resilience 2.0 capabilities is companies are no longer thinking of resilience as a strategy for survival.

11:01

It has now become an opportunity for growth.

11:05

Companies are putting more effort into digitizing their engineering, supply, production, and operation.

11:12

Only then can they take advantage of solutions, like digital twins, and emerging technologies, like Generative AI, which help them adapt faster to sudden change and take data-driven real-time actions.

11:25

Based on our research, it has been demonstrated that businesses investing in resilience building capabilities, the Resilience 2.0 capabilities, and improving digital maturity significantly outperformed their peers.

11:41

Investments in core digital capabilities have also yielded better revenue retention and product lead times.

11:47

So some statistics around this: early adopters or the quartile of companies that are the most resilient, who have embraced these 2.0 capabilities, are already generating additional revenues of 830 million.

12:03

They have captured 3.6% more growth than the less resilient companies or in the bottom quartile of our research studies.

12:11

They were able to grow more profitably, achieving an additional 1.2% points in the EBIT margin.

12:17

Now, we've talked about this earlier, with an estimated 1.6 trillion of potential revenue being left back on the table each year, on average, this is definitely a price worth fighting for and helping build Resilience 2.0 capability.

12:32

Richard Howells: It's great to see that companies that have built resiliency into their processes are actually in a position to see a disruption, sometimes, now as an opportunity because they have the ability to respond.

12:46

They have the agility to respond. They have the business systems to respond.

12:51

Nicole Smythe: And Sunita, I loved what you said about this being an opportunity for growth, because many companies can see this as a daunting act in becoming more resilient.

13:00

They question where to start, how to do it.

13:03

It's often the end goal, but sometimes there's no real plan on actually getting there.

13:08

So what are you seeing as the key actions that companies should take today to become more resilient?

13:14

Sunita Suryanarayan: And that's a great point, Nicole, right? Because I think the mindset shift of going away from thinking about it as a cost of compliance or thinking about it as anafterthought truly has changed in thinking about an opportunity for growth, and how do you use resiliency for competitive advantage?

13:34

So the three actions we have come about in our research are pretty simple.

13:40

First, invest in visibility, predictability, and continuity focused tech.

13:46

And I'll get to you in a minute on what I mean by that.

13:49

Second, adopt the mindset shift of shift left engineering capabilities, embed resilience in design.

13:57

And lastly, develop a multi-skilled workforce for agility.

14:01

So let's go into each one in detail, right? When we talk about investing in tech for visibility and predictability, what we saw is, today, many companies operate in siloed environments with very limited visibility, and they rely on centralized supply and production network.

14:18

Only 11% of them have near close to real-time alerting to disruptions, 78% need at least a week to fully understand the damage.

14:29

To respond faster to disruptions, companies must make supply chains and production processes more transparent and predictable.

14:36

They should adopt resilience practices like demand foresight and smart end-to-end control towers.

14:42

They should also strive towards reconfigurable supply chain networks and autonomous production to gain real-time visibility and control over the entire value chain, from suppliers to customers.

14:54

So what do we mean by this? Demand foresight capabilities provide the structured analytics and customer trend insights to drive new offerings and help arbitrate demand in times of shortages.

15:08

Smart end-to-end control towers, for example, provide scenario analysis and real-time end-to-end visibility to provide early detection and correction of operations issues.

15:20

Reconfigurable supply chain networks and autonomous production provide the flexible backbone to dynamically change operations at a site or shift from one site to another to maintain production levels when faced with an ongoing volatility.

15:36

On the second front, we talked about embedding resilience in design.

15:40

Businesses are constantly under pressure to increase resiliency, but at the same time, they have to reduce costs, improve cycle times, enhance product quality.

15:50

A shift left strategy appends the status quo to help them achieve these goals.

15:56

It enables resiliency in engineering by moving activities earlier in the development process, allowing companies to get products, processes, and ways of working right the first time, address potential issues before production begins.

16:13

These capabilities help companies see the potential impacts of disruption on the product at the time of design, which will significantly help them reduce lead times and improve customer and revenue retention.

16:26

In our survey, we found that the number of executives planning to increase design for resiliency will jump from 17% today to 63% over the next three years.

16:38

And that is a pretty big jump. Shift left has also been a pretty important concept when you start thinking about sustainability.

16:48

By involving suppliers and customers early with a shift left approach, companies can also address evolving customer needs and expectations before they lead to dissatisfaction.

17:01

Tighter environmental regulations mean that companies must also add sustainability considerations to product design processes, such as their carbon footprint, environmental impact, and circularity.

17:14

By using an eco-design approach that shifts left, companies can integrate sustainability principles into product design from the onset and embed them throughout the value chain.

17:25

Finally, we talked about a multi-skilled workforce for agility.

17:29

Resilient businesses need decentralized decision making where frontline teams can quickly make decisions close to where the operations happen.

17:39

These teams should have access to emerging predictive and data-driven tools that enable them to make prompt decisions and improve recovery times in the face of disruption.

17:50

But for the more agile organization model to work, employees will need the skills to effectively leverage these advanced capabilities.

18:00

Our research indicated that only 17% of the companies today have a multi-skilled workforce.

18:07

68% plan to invest in it by 2026.

18:13

While specialized knowledge in areas like procurement, operations, productions, and logistics will always be important, digitally literate, multiskilled, and cross functional thinkers who understand the big picture will also be invaluable in helping companies adapt to the new complexities.

18:32

So, three things in total: invest in tech and visibility, adopt shift left engineering capabilities, and build a multi-skilled workforce.

18:43

Nicole Smythe: And I think those three sum it up so beautifully because, so many of the actions, like you just said - the real-time visibility,sustainability being embedded into processes and having data-driven tools - they really go hand in hand in investment into technologies.

18:59

You know, one of the main things that you called out was that 11% have real-time alerting, which we know can certainly get increased, and that could be improved through networking capabilities and solutions.

19:11

Of course, to have these actions actually put into place when companies are starting this journey, how can business systems and technologies help in aiding that process?

19:22

Sunita Suryanarayan: So, everything we have discussed about today, right, Nicole, is systems and technology are the foundation or the digital core for the businesses to increase efficiency while transforming to become resilient.

19:35

We've talked about various resilience capabilities, like smart end-to-end control towers, where technology is the core resilience enabler.

19:43

Let's think about autonomous production systems.

19:46

It's a low carbon industrial system capable of quickly and seamlessly reconfiguring and correcting to adapt to change.

19:54

Digital twin simulations, helping organizations see vulnerabilities in their supply chain, simulate the behavior of their supply chain under heavy loads, build robust mitigating plans throughout their planning processes.

20:08

All of these technologies and systems are designed to help improve efficiency while building resiliency.

20:16

Now, what we have seen to date is many companies, in the past few years, applied short term fixes to their global complex production and supply networks.

20:27

They were designed for just-in-time deliveries and to be only as cost efficient as possible.

20:33

But now, when they are strategically redesigning them for sustained resiliency and sustainability, we can think of examples where up to 80% of a company's upstream emission come from Tier 2 suppliers and beyond, right?

20:48

So, Tiers 3, through all the way to Tiers N.

20:51

Most businesses today are unable to detect and track where supplier emits how much.

20:58

One central action companies should take is integrating emissions into their supply chain control tower and complement the control tower with a digital twin of the supply chain.

21:08

This virtual replica will not only map physical material flows and uncover sub-tier suppliers and risks, it can also simulate the carbon footprint of the entire network.

21:20

This example shows you how rapid innovation in data, AI, and other technologies provides ample opportunity for businesses to build Resiliency 2.0 capabilities.

21:32

And, truly, companies that invest in their digital core will be the best positioned to get ahead of disruption.

21:39

Richard Howells: It's interesting because at the start of the year, we wrote a predictions blog and we talked about the three big things being risk resiliency.

21:47

supply chain sustainability and supply chain visibility.

21:51

And you've echoed that in what you've talked about here.

21:55

And also, back in November, there was an announcement that Accenture had collaborated with SAP to establish a comprehensive Supply Chain Nerve Center to improve that visibility even more.

22:06

And we'll actually be talking to your colleague, Michel Roger, in a future episode to delve into details about the Supply Chain Nerve Center.

22:14

But could you give us a teaser about it in this episode?

22:19

Sunita Suryanarayan: Sure, Richard. The SAP Supply Chain Nerve Center aims to help companies establish responsible and resilient supply chains, reduce the risk of disruptions by providing real-time visibility into supply chain operations.

22:33

So what we do there is we use cloud data, artificial intelligence and analytics to provide n-tier transparency, right?

22:41

Looking into sub-tiers two and beyond, allowing organizations to proactively identify risks beyond their tier one suppliers, createwhat-if scenario models to assess impact of disruptions, and allow for mitigating actions to improve overall supply chain resiliency.

22:59

All of this is core functionality in the Nerve Center, and obtaining sub-tier visibility to achieve sustainability goals, identify potential, stress test, and riskexposures within the supply chain are core to when you start thinking about reducing risk, and enhancing visibility, and supporting an organization's sustainability goal.

23:24

So, I know you will go into this topic at depth with Michel, but this was just a high level teaser on how we can bring visibility and real-time alerting fromdisruptions and thinking about stress testing your supply chain to understand the impact of disruptions to create mitigating actions coming together with a control tower.

23:45

Richard Howells: That sounds great. It's as we said earlier, it's turning risks into opportunities if we have the data to make those decisions.

23:52

Sunita, we're, coming to the end of the podcast and we have one final question that we ask all of our guests.

24:00

And as we're talking about the future of supply chain, that's basically the question, what is the future of supply chain?

24:08

Sunita Suryanarayan: So, the future of supply chain is going to shift towards a more localized, reconfigurable and decarbonized value chain.

24:16

What I mean by that is the future of supply chain will focus on reducing carbon footprint, adapting to local market demands, and enhancing flexibility in response to dynamic conditions.

24:29

Advanced technologies like IoT and Generative AI will drive automation, visibility, and data-driven decision making will play a key role in shaping the future of resilient and sustainable supply chains.

24:44

Richard Howells: That's a great summary. Thanks very much.

24:47

And thank you for joining the series and for an engaging and informative conversation.

24:51

It's been great to listen to you and talk to you.

24:54

Sunita Suryanarayan: Thank you so much, Richard and Nicole. This has been extremely enlightening, and I'm very happy to have shared my thoughts on this here.

25:01

Richard Howells: I'm sure everyone will appreciate it, as well.

25:03

And I'm sure that there'll be looking to get access to that research.

25:06

So, to learn more about the research, and what we've talked about today, we'll include links in the show notes with additional information about how to actually get that data.

25:16

I'd like to thank everyone for listening. Please mark us as a favorite.

25:19

You can get regular updates and information about future episodes, but until next time from Sunita, Nicole and I, thanks for discussing the Future of Supply Chain.

From The Podcast

The Future of Supply Chain

The Future of Supply Chain podcast is a show hosted by Richard Howells, Sin To, and Nicole Smythe. The trio discusses hot topics, best practices, and the latest innovations to deliver a risk-resilient and sustainable supply chain. The show features interviews with experts from the world of supply chain, sustainability, and Industry 4.0, who will address the issues of today and tomorrow. This is an ideal podcast for supply chain, R&D, manufacturing, logistics, and operations executives to learn and share ideas and best practices with their peers.Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

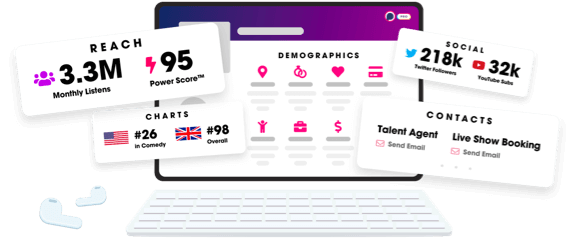

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us