Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:00

Dan Minotti: So I think the future supply chain will need to provide greater trust and transparency across the end to end, from the producer to the consumer.

0:12

Richard Howells: Welcome to the Future of Supply Chain Podcast.

0:15

My name is Richard Howells. I'm a Vice President for Thought Leadership for SAP's ERP Finance and Supply Chain Solutions, and I'm joined by my wonderful co host Nicole.

0:25

Nicole Smythe: Hi everyone. I'm Nicole Smythe and I'm a blogger, podcaster, and marketer in the supply chain space here at SAP.

0:33

And today we have a great episode ahead with two incredible guests, Dan Minotti and Brannon Lockhart, from EY, to discuss the factory of the future and the newest innovations in the manufacturing realm.

0:46

So, welcome Dan and Brannon. Thank you so much for joining us here today on the podcast.

0:50

It's really great to have you two on. And like I said, we're excited for a great episode ahead.

0:56

So if you could take a moment to introduce yourselves, dive a bit into your background and, of course, what you do today at EY.

1:04

Dan Minotti: Thank you for having us. We're very excited to be part of this podcast today.

1:09

My name is Dan Minotti and I'm a partner in our EY technology practice serving many of our global CPG, Food, And Agribusiness clients, driving business process transformation, tech and op model transformation.

1:23

I lead our EY Nottingham Spirk Innovation Hub, from a tech perspective, with a heavy focus on our SAP capabilities.

1:32

A little bit about me. I joined EY almost four years ago now, this was just when COVID was ramping up.

1:40

And you know, my initial role here at EY was to build out this EY Nottingham Spirk Innovation Center, which is a 60,000 square foot facility located in Cleveland, Ohio.

1:52

I grew up in Northeastern Ohio where my parents both worked in the factory, right?

1:58

And my dad worked in the steel industry, my mom worked in automotive, and I had the fortunate opportunity to work with General Motors for four years.

2:07

And I personally love being out in the plant and, you know, solving problems.

2:11

And so I've always had a passion for manufacturing, graduated with Mechanical Engineering degree.

2:17

My first 10 years out of college was focused on continuous improvement initiatives in the plants.

2:23

So think of like all of those MES systems, control systems, and stitching that together with SAP.

2:30

I've had the fortunate opportunity to meet Brannon and work with him around co-innovating with SAP and other tech partners to build out our future SAP cloud capabilities.

2:40

So when I think of cloud capabilities with SAP, that's Digital Manufacturing Cloud, Asset Management, Field Service Management, Maintenance, and some other proprietary EY tools such as Intelligent Insights.

2:55

You know, one of the things that we try to do as part of our center and at EY is place a heavy focus on helping our clients better understand some of those industry shifts, right?

3:05

So how you reimagine new business models, new products, new services, all powered by new digital cloud SAP tools.

3:14

So that's a little bit about me. Nicole Smythe: Awesome.

3:17

Love the full circle moment. Brannon, how about yourself?

3:21

Brannon Lockhart: It's a pleasure to be here with everyone, my name is Brannon Lockhart.

3:25

I'm a manager at EY. I've been with the company going on five years now.

3:30

I live in Kentucky, but I was born and raised in Alabama, if you're wondering about my accent a little bit.

3:37

My background right now, working with EY, I'm the SAP Lead for Nottingham Spirk.

3:44

I'm in charge of our GDS team, our Global Delivery Service team.

3:48

We have about 20 people on our team that we build out to use cases demos and everything to get ready for clients.

3:56

I have roughly about 12 years experience in industry.

4:01

Most of my background is around industry, this is my first consulting job that I've had.

4:06

So, a lot of my experience is on plant maintenance background.

4:10

I've been maintenance, millwright electrician, been a supervisor, manager, plant manager, and, maintenance planner, so I have a lotof real world experience when it comes to anything related to the different plants and the different industries that we work in.

4:29

And so to be able to bring it to EY and to Nottingham Spirk is really exciting for me because I get to help people out with their problems with the new age technologythat we have here at EY and everything that we're doing is just an amazing thing to see and to be able to help our clients achieve their goals that they want to achieve.

4:50

So thank you again for having me. Nicole Smythe: Well, thank you both.

4:54

I mean, we have two of the best experts, I'd like to say, for the conversation we're having today.

4:58

So I know for a fact it will be a great one.

5:01

But, let's start off with a general question as, you know, I'm sure many of our listeners have heard the terms Factory of the Future, Smart Factory, Digital Hubs, and so on and so forth.

5:13

But, we can't overlook the challenges that sparked the journey to this innovation.

5:18

So in your opinions, what are some of the top challenges in the manufacturing space that you're both seeing today?

5:25

Dan Minotti: Yeah, I'll start out and maybe share two.

5:28

This is based on, you know, my work with a few global CPG Food and Ag clients that come top of mind for me.

5:37

One of the challenges we see is these organizations really trying to optimize across the entire enterprise, right?

5:45

And I think part of it is how these organizations get out of their organizational silos, right?

5:51

So what do I mean by that? I think it's so important, you know, where you have Sales and Marketing working much more closely with Supply Chain.

5:59

And so how that then drives into your demand planning, your supply planning, your product development, which then ties into your manufacturing.

6:08

And part of this is focused on really working as one team.

6:13

And this is part of what we're trying to do and achieve at Nottingham Spirk is bring the collective organizations together to solve some of these problems.

6:23

So that's the first one, optimizing kind of across the entire network and really understanding some of those challenges in manufacturing.

6:31

The second that we're seeing is, you know, these legacy businesses are struggling to keep up with some of these industry shifts, right?

6:38

Which is putting more pressure on operating as one team.

6:42

I'm going to give an example. So, in the Food and Ag industry, especially the Ag industry, when you think of the ABCD's, you know, they have a history of selling volume or product.

6:54

And there are new entrance into the market, which is taking market share and pricing from these organizations.

7:04

And this is requiring some of these legacy organizations to rethink these business models.

7:10

And what we're seeing is a shift to more outcome-based business models, products, and services tied to those customer needs.

7:19

So, when you think of the implications of that, this is placing a ton of pressure on supply chain and manufacturing to be much more agile and responsive.

7:30

And these legacy organizations are not set up this way today.

7:35

So this is going to require additional capital investment to pivot some of these organizations.

7:41

So those are maybe two. I know Brannon has a few more that he would like to share, as well.

7:48

Brannon Lockhart: Yeah, I think the biggest things we're seeing is the re-imagining of new ways of working, powered by AI in manufacturing.

7:55

You know, it requires the new skills for any type of individual, and to maintain the AI.

8:03

And we're not just using, what I'm used to in the golden days, I guess, the PLC programming.

8:09

You don't have the fully integrated systems with the work anymore with the PLCs.

8:14

And, as me and Dan has talked over the past year or so, I remember going through an operational excellence one time, where we were trying to build world class maintenance.

8:24

And, you know, one of the big things at that time, and this was probably 10, 12 years ago, was you can have all this new age technology and all thegoodies, and the goodness to make your life a whole lot easier, but if you don't have your people on board with that, then it's never going to go anywhere.

8:43

And, you know, one of the things that they talked about was the paradigm shift; and that's, you know, taking the individual way of thinking and theway we've done it for 35 years and changing it to over here, the way we're doing business now and the way the client or the industry is wanting to go.

9:01

And it's a really hard thing to do is to change somebody's mindset of the way they've always done things versus the way we want to do things now.

9:10

And another piece of that is the lack of skilled workers, because you're talking about, going back to my industry days of plant maintenance, working in limeplant, you know, I'm there at 22, 23 years old, and I'm working with these guys that are in their late sixties that's been there their whole entire life.

9:31

They're used to doing one thing a certain way, and that's the way we're going to do it.

9:36

And so when they start retiring or leaving the company, then you're left with young guys, like me, at that time, and I'm still trying to figure out how to do this, you know, or how we're going to do this.

9:48

And so, it takes a lack of skills and the employees that you have now that you want to build these skill sets up to make it easier for them to be able to use this new age technology, like AI in Manufacturing.

10:02

And then you take on a whole new set of issues like automation issues and consumer trends because as we know trends are happening all over; youknow we may go out and we may buy this this time and it may be the hot item for about two or three months, and then here comes this other hot item.

10:21

So you're automatically having to adjust to the different trends.

10:24

With the automation piece, you're no longer in the PLC program where you connect to the equipment and make the changes and then run the equipment.

10:33

Now it's all AI based in Manufacturing.

10:36

So there's a lot of great things happening, but a lot of scary things happening too, when you look at your workforce and the people there and the changing of minds and all these new innovative ideas.

10:49

Dan Minotti: You know, a lot of times when we have these workshops with senior -level client executives at our center, they're always being sold the new kind of shiny object, right?

11:01

But then when you're walking them through, and you're beginning to describe what impacts are to the organization and how they need to pivot the light bulbs start going off.

11:13

Executives want to move really fast.

11:16

But the key constraint, right, that we are seeing is the people.

11:21

Nicole Smythe: Absolutely. I was going to say, you guys made a great point earlier about change management.

11:27

And I think a lot of the times people are so focused on change management from a pure technology perspective, you know, transitioning from the old software to the new.

11:35

But the most important part, like you said, is the people, you have to manage the people and how, you know, they bring that institutional knowledge of the factory, of the workers, of things like that and really making that adaptable for them.

11:46

So as much as the technology needs to be agile, the people do too, as well

11:51

Dan Minotti: to bring them along. Nicole Smythe: Mm-Hmm. Absolutely.

11:54

And make them feel as though they're part of it too.

11:56

Brannon Lockhart: Yes, yes. Richard Howells: You spoke about some of the top trends and you covered a lot of topics, like optimizing across the enterprise, and making sure that people collaborate both within the organizationand with their suppliers and partners and customers, the changing business models as industries shift - and the as a service model springs to mind there as an example - and the need for agilityand responsiveness, reimagining the way we work driven by AI, and the changing workforce, which is a big topic that we've talked about before in this podcast; where you're losing skilledworkers and you have a new generation that you're trying to recruit into the workforce that wants to leverage this new technology, and how automation can help also address the challenge.

12:40

But what are some of the ways that you're seeing companies address some of these challenges?

12:46

Brannon Lockhart: I'll take that one. I think for us at Nottingham Spirk, one of the cool things that we get to do is actually bring the clients in physically to our Innovation Hub there in Cleveland.

12:59

And I think that is huge because we have a working system we can go through, we can show the journey of different things that we have done and built at the hub, and then we canwalk the clients through that journey to demo the different type of systems we have, the different capabilities we have, especially with our SAP systems and what we've built.

13:22

And one of the really cool things that we do before we bring the client in is we get an understanding of where they're at, what they're wanting to see, and we build our use cases around these things that the client are wanting.

13:36

So when we bring them to the hub, we're actually able to show them what they were wanting to see, how we can change their mind on the different capabilities we have and the different things that we do.

13:50

And once we walk them through that journey, you know, we're waiting to see that 'wow' moment, or this is exactly what we want to see, and we've had a lot of those moments, you know, especially with SAP and other clients that have come in.

14:05

But after we walk through that, then we have an area that we call our wave space that we sit down with the clients and we let them talk and say, what they've seen, what theylike, what they don't like, how this could work in their environment, or different things that they would like to see in their environment that they could use that we've built.

14:25

And then we use that as a collaboration to be able to talk out loud and bring these things to life with them, and then to go back and have a blueprint that we can start building off of.

14:37

And, you know, one of the cool things about it is once we build this out for them, we know this is going to be in phases, but the clientare actually able to come back to the hub, and we're able to show them where we're at in the different phases and what this would look like.

14:53

And we bring this to life and especially with the trends that are happening now with AI, the IoTs are really huge, the cloud, the network and connectivity is like really big for us right now at the hub.

15:08

And, every organization's moving quickly to the cloud, so we're able to bring people in to see exactly, you know, what the cloud is about, how we built the technology on top of the cloud, how weuse the cloud for the connectivity, and what we're doing to drive the improvements of skills, and the new capabilities for the skilled workers and everything that's being done on the shop floor.

15:33

Dan Minotti: In the future state, right? Showing that future state, but a lot of times we're trying to use the client's data too, to make it very, very real and immersive, and set it up in a way that the clients can relate to what they're seeing, and touching, and feeling, right?

15:50

Richard Howells: Do you have specific examples where customers are actually re-imagining the way of working?

15:55

Leveraging AI and IoT, for example.

15:59

Dan Minotti: I'll take one example here, Brannon.

16:02

So we have one customer, that let's just say in the agribusiness space, they recognized the fact that they sell, think of like crop inputs to the producers.

16:14

Okay? And it's a volume based business, right?

16:19

Where they're selling products. And, from that volume based business, they knew based on where the industry is going, smaller entrance, like more Amazon-like players, are coming into the market that they were going to be disrupted into the future.

16:35

So they needed to do something different. So this is where our hub could help really take a look at the new business models, the new services, the new products, right?

16:45

To envision the future based on where the industry's going.

16:49

And, based on that, build the future digital tech stack to enable that.

16:55

And so when you think of AI, in this example, there's a lot of information sharing between customer and client organization.

17:05

And getting into prescriptions, in this example, where the AI is so important to define it, right?

17:14

The right prescription is for this customer and you have to think of the implications and supply chain, demand plan, supply planning, how they schedule the production floor.

17:25

Now, they're going to need to do changeovers much more frequently because they're running smaller backs.

17:30

There are capital investments that you have to think through the organization.

17:35

So this is where the AI, the IoT, those types of things, implementing it in a greenfield way, so it's cost effective into the future.

17:45

That's one example. Richard Howells: No, that's good.

17:47

Thank you. Sort of brings it to life. Dan Minotti: Yeah, so hopefully that's helpful.

17:51

Nicole Smythe: Absolutely. It's funny too, I actually went to school at an agricultural school, but went for business.

17:58

So kind of strayed a little bit from the norm.

18:00

But it is so interesting to have the business background of it, but now kind of hearing how AI is getting intertwined in it because being there seeing how agriculture works, but then how, you know, new technology can now be intertwined.

18:13

It's amazing to hear. So, thank you so much for that example.

18:17

But, the hub itself, you know, is built on five main innovation pillars from what we've been told.

18:22

Can either of you or both of you dive a bit into what those pillars are and how they're represented throughout the space as well?

18:31

Brannon Lockhart: Yeah, sure. I'll take the first one.

18:33

So we have a slide that we always show of our pillars and where we're at.

18:39

And it's basically when we bring somebody into the hub, we have certain areas that are built around our hub.

18:47

And so we use these as stopping points for our pillars of where we're at.

18:54

And I'll go down the list of them, as our business model innovation, and this is basically where we're showing the model of what we're looking at, what theclient that's coming in is looking at, we look at their model, we look at our models and the things that we could use to help them there at the innovation center.

19:14

You know, if there's design changes that need to be made, if there's software changes, anything within that realm, we're looking at in that phase.

19:24

And then the workforce re-imagined. So for us, when we think of the workforce re-imagined, that is what we're looking at that w e could rework for them to make them work for theclient, whether it's equipment, whether, again, a software changes, or the whole full blown journey of building this type of system out for.

19:46

And then the a big one for us to touch on is the customer experience because when we bring somebody into the hub, like I said, I'm always looking for the 'wow' moment of seeing what the client's face is looking like when we show them whatwe have there and the biggest thing is, you know, to be able to take the client's data, to put it into our EY systems and capabilities that we've built, and to be able to show the client what it looks like on the screen at the differentmanufacturing stations, the IBPs, the EWMs, the ESGs, and all those different stopping points of in the journey is absolutely amazing to see the client and their reactions when they see their data there and what it could do for them.

20:29

So the customer experience is probably my favorite part of it.

20:33

And then we have the product and service innovation of how we take the products and we build that out for them in our systems and how we use that to innovate across whether it's the cloud technology, whether it's the AI or the manufacturing piece.

20:48

So that's another great piece that we have.

20:51

You know, and we work with a host of ecosystems and partners at the hub to bring these clients to us and across all the technology that we have there and for each industry.

21:02

So the cool thing about what we have at Nottingham Spirk is we're not just servicing the Consumer Products side or the Power and Utility side or the Oil and Gas side.

21:17

Everything that we've built at Nottingham can be used across any type of industry that we have...

21:23

our Life Science, Power and Utilities, Oil and Gas, Consumer Products, AM&M.

21:29

You know, we can use this across any type of industry, and that's what makes us very unique there at the hub and what we do.

21:38

Dan Minotti: Maybe add to what Brannon saying here, right?

21:40

Across those 5 pillars, I think one of the ideas here, right, is every client is at a different place along the journey.

21:49

So, you know, you think of some clients or they're just trying to play the game better...

21:53

like, hey, just help me improve OPEX in my plants versus other clients are really trying to change the game, be very disruptive with new digital platforms, new products, new service models.

22:06

So, a lot of times we have to center around, like, what is the business problem or the challenge?

22:12

And then how do we intersect with the capabilities we should be bringing to bear?

22:17

But then also, how do we stretch the thinking a little bit?

22:20

We're not trying to stretch it too far and overwhelm them.

22:23

So, that's important because then we can bring to life various aspects of those five pillars across business model innovation to the impacts to the humans at the center, the experience and some of those things, right?

22:37

That's important context. And it's an important learning that we always say, what's the business problem?

22:42

What's the challenge we're trying to solve? Richard Howells: Yeah, I've had the pleasure of virtually going through the Nottingham Spirk facility and you're right...

22:50

you could completely overwhelm company that's not ready for all of this.

22:56

And just got to lead them through gently and work out where the next right step is.

23:00

Every company is different, is it? Dan Minotti: So important.

23:03

Richard Howells: So, with that in mind, how are you seeing innovative spaces like the Nottingham Spirk Hub help to break down thedepartmental silos you talked about at the start and create that connected customer experience you mentioned in the last question?

23:19

And what are some of the ways that EY is continuing to build in the white space areas with your partners to achieve this?

23:26

Dan Minotti: Yeah. So, this was about four years ago when, you know, I first joined the team and this was right during COVID, I had the opportunity to go to the Nottingham Spirk evenbefore we formalize this partnership, and one of the powers that I saw at the center was the thought process of starting with the customer, or the consumer in the need.

23:51

And starting there, but then looking across the entire organization, right?

23:57

So the client serving that customer need, right?

24:00

Or the company serving that need. And what was very apparent is they had in a collaborative room, R&D, Sales, Marketing, Supply Chain, Manufacturing, right?

24:14

Working through the problem, looking at it from various dimensions, that was like an 'aha' moment for me, of really how you think about solving some of this.

24:23

So one example is Nottingham spirk has been working with this dairy foods company to launch a new business, and this new business is being launched into the market.

24:35

And, one of the things we set up, in support of that new business, is a cloud stack.

24:41

So this is all SAP cloud capabilities.

24:44

Microsoft is the cloud backbone to that and where we're able to simulate and run that business end to end.

24:53

So, think of point of sale in a retail environment to how that IoT and that connectivity flows into SAP, Order Management, SupplyChain, Manufacturing, being able to look at that tight interlink between demand, supply, and the production schedule, right?

25:11

And I think a lot of our clients, they're challenged in the sense that these systems aren't connected, right?

25:16

Richard Howells: And in the dairy industry, you're talking about very short cycles and short shelf lives, as well.

25:21

Dan Minotti: Correct. Very short shelf lives and traceability now, right?

25:25

And so that's one example of the power of EY, Nottingham Spirk, and our client, and the ecosystem partners to bring these things to life.

25:37

Richard Howells: Great example. Brannon Lockhart: Yeah, and I think on the flip side of that, when we bring clients and customers through the hub, one of the things we show them is the dairy demo that we've built and the e-bike.

25:52

And one of the cool things about the e-bike is we're able to take this bike with the batteries that's connected to it, and we're able to sell the bike, but the customer who buys the bike is able to buy different packages and different levels.

26:07

So, you may go 30 miles an hour when you first get the bike, just tooling around Cleveland, or you could call back and you say, hey, I want to bump my package up to where I can run 70 now up and down the interstate.

26:20

That is the new age technology of which we have around the manufacturing and the AI stuff but also with the IoTs because they're taking thedata from the bike and they're sending it back to the system to where they can do the predictive and preventive maintenance of the AI piece.

26:40

So they're saying, hey, this is when we need to bring this back down, this is when you need to do this service at this many miles, and so.

26:48

When we looked at that and we're able to bring up this dashboard of analytics that we've built, we're able to show each bike, where each bike is in theassembly, where it's at running, you know, if we have any issues with the batteries, if we have fan issues, if anything's restricting the bike to do its job.

27:08

It's a real time data on your phone or to the computer to where you're actually seeing these issues.

27:15

And so when we work with this and we developed this system, we started showing this to other clients that were coming in, and we got that 'wow' moment again,but we were also able to use what we have with the cloud technology, and sell this to another client that's in the battery manufacturing business, as well.

27:36

So we've taken this new age cloud technology for batteries in bikes, and we've used it across to another client that are doing the same thing, but in a different industry, they're recycling their batteries.

27:53

And so, for me personally, it's amazing to see how these things work being, my background is plant maintenance, where I'm usually working on these things and seeing it in real life data, but also to step out of the box and see the new agetechnology, like AI, the manufacturing piece, the DMC, and the stuff we're doing at Nottingham Spirk and learning how we're using that across the industries is totally amazing to me to be able to see those kinds of things and the effects that it has.

28:26

Richard Howells: In that second example, are they doing it as a service model, as well, with the electric bikes?

28:32

As in, they're not selling the bikes, they're basically billing based on miles ridden or whatever.

28:37

Dan Minotti: Yes. So that was something that we helped define, that as a service model, and the financials behind it, because that was an important piece to get funding.

28:49

Richard Howells: Yeah. And it also goes back to the design of the bike as well, because you've got to have sensors on the bike that capture the information that enables you to bill based on usage.

28:58

Dan Minotti: Yes. Nicole Smythe: Absolutely. Awesome.

29:01

Well, thank you both. Such great examples. And I've never been to Cleveland, but I think I might have to try to expense a trip here to come see this hub.

29:09

It just sounds awesome. And the work you guys are doing is incredible, and, you know, especially with SAP here.

29:15

So thank you both for your insights and everything.

29:18

Dan Minotti: Would love to host you. So

29:21

Nicole Smythe: We'll take you up on it. Dan Minotti: Just not in the winter, not in January.

29:25

Nicole Smythe: Exactly. I know we might not even be able to get there weather wise, you know, maybe we'll do a nice spring or summer day.

29:30

But thank you both.

29:33

But, you know, it's crazy to believe, but we're already near the end of the podcast and given the series name is the Future of Supply Chain,we ask every guest the same question, which we're excited to hear both of yours, but, in a sentence or two, what is the future of supply chain?

29:51

Brannon Lockhart: I think for me, the future of supply chain, we will need to be more agile and dynamic.

29:58

You know, we will need to be able to respond to a change in demand and product mixes and it will be driven by customer needs, and not the products and processes, I believe.

30:10

Nicole Smythe: Great answer. Thank you. Dan Minotti: So, I think the future supply chain will need to provide greater trust and transparency across the end to end, from the producer to the consumer.

30:24

Richard Howells: Well, two great answers that dovetail with each other.

30:27

That's perfect. So, Dan and Brannon, thank you for a great conversation.

30:32

Dan Minotti: Thank you for having us. Brannon Lockhart: Yes, absolutely.

30:34

Thank you. Richard Howells: I'm sure you will be back. Nicole Smythe: Hopefully one day in person soon.

30:40

Richard Howells: And thanks everyone for listening. Please mark us as a favorite and you can get regular updates and information about future episodes.

30:47

But, until next time from Dan, Brannon, Nicole, and I, thanks for discussing the Future of Supply Chain.

From The Podcast

The Future of Supply Chain

The Future of Supply Chain podcast is a show hosted by Richard Howells, Sin To, and Nicole Smythe. The trio discusses hot topics, best practices, and the latest innovations to deliver a risk-resilient and sustainable supply chain. The show features interviews with experts from the world of supply chain, sustainability, and Industry 4.0, who will address the issues of today and tomorrow. This is an ideal podcast for supply chain, R&D, manufacturing, logistics, and operations executives to learn and share ideas and best practices with their peers.Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

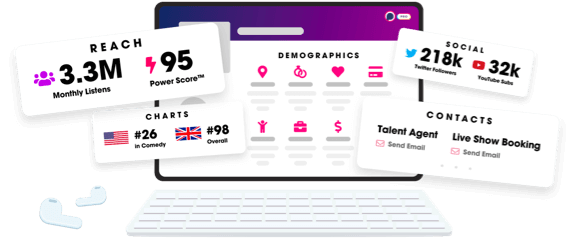

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us