Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:00

If we look into that for me, theend-to-end visibility of our value chain.

0:04

So not just the supply chain, theend-to-end value chain, that next

0:08

year will become absolutely critical.

0:11

And for that, we need to make sure that wehave the data and we have the technologies

0:15

to rapidly address all the issues thatcome from a consumer, a customer, or

0:22

a political and economical nature. That is, in a nutshell,what I expect into 2024.

0:29

Welcome to the Futureof Supply Chain podcast. My name is Sin To and I'mmarketer, blogger and supply

0:33

chain podcaster here at SAP. Today's episode is about the product oran industry that almost everyone knows.

0:39

And I'm very excited to welcome HugoTimmermann from Heineken today and

0:43

to talk with him about the worldof brewing and challenges it has

0:45

faced in recent years, and maybewill continue to face in the future.

0:50

But first welcome Hugo and thank you somuch for joining us today in the show.

0:54

Could you please take a momentto introduce yourself and give

0:57

some insights into your role? Yes, of course.

1:00

And thank you, Sin. Just a few words there.

1:02

I'm responsible for what we call digitaland technology for the global supply

1:06

chain within the Heineken company. And as hopefully, you know, andmany others, Heineken is the

1:12

world's second largest beer companywe've existed for over 150 years.

1:16

So, we have a massive legacy. And we are very proud to be the mostinternational brewer on the planet with

1:23

more than 300 brands in 190 countries.

1:26

And with 85,000 employees or morethan that actually we produce and

1:31

we distribute more than 250 millionhectoliters of beer, of which the

1:37

Heineken brand is more than 20%. And if we look into our globalambition, one part of that is to be

1:43

the best connected brewer, means weconnect to our consumers, we connect

1:47

to our customers, but also within oursupply chain and to our suppliers.

1:52

And we are at the moment in the middleof a massive digital transformation where

1:57

we are moving from quite a federatedlandscape where most operating companies

2:02

have their own digital estate to whatwe call a global digital backbone where

2:06

we aim to align processes, data, andsystems, so that we have an end to end

2:11

transparency and we can actually benefita lot more from our global footprint

2:16

and to deal with, I think some of thesupply chain challenges that we will be

2:19

talking about later on in this podcast. Thank you so much for the introduction.

2:24

So as you said, Heineken isinternational well known as one of

2:28

the biggest brewery in the world,and it's also one of the largest

2:31

brewery groups in the world, right? But however, the beer industry is, orhas been facing a number of challenges

2:37

like other industries too, due to theCorona pandemic and the war in Ukraine,

2:41

such as supply chain disruptions,price increases, rising inflation,

2:45

and also a tight labor market. So these challenges have led to adynamic development in the beer industry.

2:52

And what's happening in the beer industryright now and how does the change in

2:56

consumer behavior affect the industryand therefore also your supply chain?

3:01

Yeah, I think you're spot on. Nothing that happens to theconsumer goods industry is strange

3:07

to us in the beer industry. So we're absolutely in the middle andso when you talk about the impact of

3:12

the Corona period, where actually insome countries we were not even allowed

3:16

to sell beer during the lockdowns. So, you can imagine what kindof impact it has to our company.

3:21

The Ukraine war and selling off ourRussian business, the Suez Canal,

3:26

shortage of containers, current consumerpricing issues, especially in Europe,

3:31

but also outside of Europe, we see alot more volatility in the market.

3:35

And in our case, we see that a lot inkey markets like Vietnam and Nigeria.

3:40

But yeah, the consumer behaviornext to that is also changing.

3:44

And that's not just based on pricing.

3:47

We also see that younger people arenot looking for a traditional beer.

3:52

We've seen a massive shift towardscraft beer in many markets, but we

3:57

also now see a big focus in what wecall low and no alcohol drinks, which

4:02

sometimes are beer and sometimes are not. So for us, that means that we'revery actively looking at our product

4:08

portfolio and we're looking at productinnovation within beer, but also beyond.

4:14

So, we're recently have acquireda company in South Africa, that is

4:18

very large in cider, which is nowa part of our broader portfolio.

4:22

So we see that we're makingmoves both in and outside of

4:26

the traditional beer industry. But all in all, if weadd all of that together.

4:30

What we see is volatility as the key word.

4:34

Whether it is in the economy, whether itis in consumer behavior, whether it is

4:39

geopolitical and for our supply chain,that impact is massive in each and every

4:44

step, whether it is in forecasting,how do you forecast on a moving base?

4:49

How do you then deal with that? From a production perspective to makesure that you brew the correct beers

4:56

to the consumer demand that mightchange by the time that you're brewing

4:59

it, to actually delivering it to ourcustomers and consumers after that.

5:03

So the integration across all ourOpcos for us is becoming more and more

5:08

critical and the end-to-end visibilityin the supply chain is one of the

5:13

key elements that we need to have toaddress those ongoing sets of changes.

5:18

As you just said, end-to-endvisibility, and we talked about

5:21

this in our preliminary discussion.

5:24

So, actually no one can deny anymorethat it is so important for companies

5:28

to have a holistic view in order tomake decisions, optimize promises,

5:34

mitigate risk, and also improve theoverall supply chain performance.

5:38

But how can companies actually achieve theholistic view and how can technology help?

5:45

Yeah, it's a very good question. And I'm not going to say thatI have a silver bullet for that

5:49

or that we have within Heineken. The key word for me is data.

5:55

We need to have more granularinsights into consumer

5:59

behavior and consumer patterns. We need to have more insight into thevarious channels and start to look at

6:05

that in a more integrated perspectivethan we have done in the past.

6:09

So it is really flowing through thedata, through the entire value chain,

6:14

and then building a tool set that allowsyou to run scenarios and analysis a

6:21

lot faster and a lot more granular thanwhat we've been able to do in the past.

6:26

So I think we're at a very fascinatingera in the technology space with the rise

6:32

of machine learning and the buzzword AIthat actually allows a lot more of that

6:38

analysis at a far higher pace so thatyou can actually utilize it a lot faster.

6:44

And we're moving from a lot moreresponsive to a lot more proactive

6:49

data analysis and planning of actions.

6:53

That for me is the big movethat we are in the middle of.

6:56

That's also why the digitalbackbone initiative within

7:00

Heineken is so critical for us. Because without that, we would nothave a standardized set of data

7:07

that we can actually benefit from. So, it's the overarchingbelief in data that for me is

7:14

the key element on end-to-endvisibility in your supply chain.

7:17

And I think that is not verydifferent from many other companies

7:22

in the consumer goods industry. But we have a long wayto go before we're there.

7:26

Yes, like most of the companies wherethey actually need to think where

7:31

they start and also when they start.

7:33

And because you have so many differentlocations around the world, it's actually

7:37

also the question in which location doyou want to start, or is it something

7:41

where you say first we start in theheadquarter and then roll it out to

7:46

others, I know it from our pre-discussion,but this is something that I really

7:50

want to touch again because it's sofascinating how Heineken is doing this.

7:55

Yeah. So if we look into Heineken,we are very, very proud on what

7:58

we call our Opco centric model. Have we've grown over the years throughmergers and acquisitions, and we're

8:03

very close to the customers in eachand every country that we operate in

8:07

and we want to maintain that model. So we believe we should not be a stronglyhierarchical top down model, we believe

8:14

in having actual operating companies. With that, what we're doing at the momenton the digital backbone is creating a far

8:21

stronger network of operating companieswhere the head office is facilitating

8:25

the interactions within the network.

8:28

So we are doing the entire worldon our digital backbone initiative.

8:34

We are starting at this momentin a few of our smaller Opcos to

8:38

test the end-to-end setup, and wewill be growing over the next five

8:42

years to cover the entire world.

8:44

All our Opcos will be thenon that same backbone.

8:48

And with that, the role of the headoffice, as I said is on strategy,

8:53

but it's also we're creating hubsthat are covering activities for

8:57

multiple Opcos so that we are closeenough to where the action happens.

9:03

But also benefit from the skillthat we have, but we're not

9:06

bringing that all to global hubs. We see a distributed set of callit center of excellence or center

9:11

of expertise, or sometimes it isa hub that does actual activities.

9:15

In Europe, we see, for example,a transport management hub that

9:18

works perfectly in Europe giventhe setup of the European Union.

9:23

But in Africa, that might work differentlybecause you have a complete different

9:27

logistical challenge in that region. So we see changes indifferent parts of the world.

9:32

We see changes in different Opcos. But we will be offering a integrated toolset with a menu of options for an Opco.

9:40

So not every Opco needsthe same advanced platform.

9:44

Sometimes it can be a simplified version.

9:46

So we give an Opco what they need, butwe want to talk all the same language

9:51

across Heineken so that we can benefitfrom our scale and allow the Opcos to

9:54

be as close to the consumer and thecustomer whilst we get benefits of

9:59

our scale, which you can also see, forexample, in our procurements that we see

10:03

that coming back at the back end of it. So, it's a quite a balanced approach.

10:08

We're not going for the one size fitsall solution that I've experienced in

10:13

previous companies that I've worked at. It's also not the easiest to achieve.

10:17

It's a massive transformationthat we do and I believe in that.

10:21

It's a lot of effort, but the outcomeof this is looking to be really

10:24

good and something different thanthe standard solution might be.

10:28

So, can someone actually say that youhave changed or that you are adapting

10:32

this kind of hybrid supply chainstrategy or how would you describe this?

10:37

I mean, as you described, thedifferent locations work differently

10:40

and you don't have one size fits all.

10:43

So if you want to be agile,you need to implement this

10:46

kind of agile process, right? But still you need to cover allthe costs and reduce that cost.

10:50

So, is this the combinationof lean and agile?

10:53

Yeah, well, of course, because it'salways a location and the lean agile

10:58

continuum, certain parts of your supplychain must be as lean as possible.

11:03

And of course, we're under a massivepressure in terms of product costs, in

11:07

terms of energy utilization, et cetera.

11:10

So lean is massively helping in thoseareas, but at the same end, you need

11:14

to have agility into your process. And if you look at lean andagile, they are in essence

11:19

part of the same methodology. And for us that centers aroundTPM in our supply chain.

11:25

On the digital side, of course, weapply agile principles and how we

11:28

bring technologies into the Opcos. We also apply lean methodologies when youtalk about service provisioning processes.

11:35

So these are in an absolute continuumand they allow us to be more specific

11:41

into the various parts of our supplychain, what we need, because even your

11:44

procurement cannot be 100 % lean, becauseyou need to have a certain agility into

11:50

the various materials that you will need. So that will always be dependent onthe consumer and the customer demand

11:57

whilst we try to balance that withas lean as possible a supply chain.

12:02

I firmly believe that our supplychain should be what I call lights

12:06

out and no touch, which means. Zero or minimize at leastunplanned manual interventions.

12:13

So we have a big initiatives aroundour connected brewery, which brings

12:18

digital and automation into theactual production sites with the

12:22

ambition of stopping minor stops andreducing losses and reducing waste.

12:27

So you want to achieve lights out,which actually means the light is

12:32

on where you need to take an action. So you do your plant actions.

12:35

You want to see no touch. Why would you have people doingplanning if the system can do it better?

12:41

But reverse also is there. You will still need people to coachthe planning systems and adjust

12:48

them because of that volatility. So you want to be lean whereyou can so that you can focus

12:52

on agile where you need to be. We talk about agile and lean and also costreduction and being agile as possible to

13:01

adapt to new market trends, to scale, tomeet also the customer expectation and

13:06

also to meet the sustainability goals.

13:11

On your website, you are writing thatyou are constantly improving your

13:14

performance, data quality and reportingfor more transparency that you are

13:18

applying the Stakeholder CapitalismMetrics of the World Economic Forum

13:22

and the recommendations of the TaskForce on Climate Related Financial

13:27

Disclosures to support this goal. Can you explain a little bit about howyou want to achieve this and how also

13:33

data helps you to become more sustainable?

13:36

Yeah, it's a very, very good question.

13:38

And yes, sustainability isa massively important topic.

13:43

And in 2022, we set out what we callour brew a better world strategy.

13:48

And a few components of that is that weplan to reach net zero carbon in scope

13:53

one and two by 2030 and actually net zeroacross the entire value chain by 2040.

13:59

So it's a massive, massive target on that.

14:01

But you also see items like zerowaste to landfill by 2030 for

14:05

our production sites in there. And another element that especiallyin our industry has a lot of attention

14:12

is of course water usage becausebeer for the largest part is water.

14:17

And more so because many times we operatein water stressed area, I think about

14:22

Mexico, think about parts of Italy, Spainand we've put a lot of targets to reduce

14:28

water usage in all our sites and evenmore so than in water stressed area.

14:32

So for us sustainability is somethingthat goes along quite broad set of

14:37

actions, whether it is specificallyabout net zero, but also how we

14:42

operate further into our organization. The one thing again, that collects allthese targets is in the end is data.

14:49

How do we collect that data fromeither source systems or many cases

14:55

at the moment it is still manual andwith the growing scope and importance

15:01

we just need to make sure that all ofthe data collection becomes automated.

15:04

And again that for me is a link backto why that digital backbone is so

15:08

crucial for us because it allowsus to tap into more source systems.

15:14

As I mentioned our connected breweryallows us to connect directly into our

15:19

machine lines and with that collect datathat we get and use for multiple purposes.

15:26

In parallel with that sustainability thenbecomes a growing part in your decision

15:30

making models in your various system.

15:33

Think of planning systems, thesustainability play a role in where

15:37

you source certain products from.

15:39

Think of transport managementas you know, logistics, of

15:42

course, is a massive contributor. How do you optimize routes?

15:45

Where does electrification of your fleetstart to contribute and how do you then

15:51

do your more dynamic routing so thatactually the battery in the truck is

15:55

full enough to reach its destination. Think of the managementof packaging lines.

16:00

How do we need to optimizeperformance for sustainability

16:03

might be different than for speed. So in all of these areas withinour breweries, sustainability

16:08

will become a growing metric. And we need all the right data forthat to become more sustainable.

16:14

And you have similar conversationsaround financial disclosures,

16:18

around this and around that. All of it centers around, we needto ensure that we have our data

16:24

in a lot more standardized way. Otherwise, it will remain manualefforts and we can do that.

16:29

It's just a lot of work to get it done.

16:32

Right. As you said, sustainability is soimportant now and to use different

16:37

data to link everything togetherwill help to reach your goals.

16:42

So that leads me actuallyto the next question.

16:45

Heineken uses the SAP S/4HANA systemand the SAP BTP for the core program.

16:51

Would you like to tell us about thechallenges you faced and how the use

16:56

of SAP solutions help you to improve?

17:00

If we look into our current landscape,I think we have top of mind 43 ERP

17:04

systems across the globe at the momentand name any flavor, we probably

17:09

have it at the moment, varyingfrom SAP to Navision to JD Edwards.

17:14

And this is a critical part of thatdigital backbone is having a lean S/4HANA

17:20

at the core of everything that we do.

17:23

So that becomes our single sourceof truth and around that we have

17:27

a variety of business platforms,a menu, sometimes of options.

17:32

Sometimes there is one option. If I think about warehouse management.

17:37

You can do it very simple in doinginventory management, but you can

17:40

also create more options around moreadvanced warehouse management systems.

17:44

And we see the same in some ofour planning systems, sometimes

17:47

foundational, sometimes more advanced.

17:49

All of that goes in a standardized wayback to our core and those business

17:54

platforms sometimes are SAP platformswhereas management as I mentioned,

17:58

this is one of those key examples. And there's quite a few more.

18:01

Sometimes and those areplatforms from other partners.

18:05

And I think the beauty of it ishaving that S/4HANA at the core

18:09

allows us to connect to differentplatforms, allows us to talk in a

18:14

single way, and we have a structuredenterprise data model around that.

18:19

That allows us more plug andplay of platforms in future

18:23

when we see the need to change.

18:25

So it allows us the standardizationthat you want, but it also allows us

18:30

the agility going forward to move up incapability or switch capabilities or add

18:37

on different capabilities in differentOpcos based on the need that we have.

18:42

Because the one thing we know forsure is what we're going to put in

18:45

place now in 2023, 2024 will not beexactly what our Opcos need in 27, 28.

18:53

The need will evolve and with S/4HANAat the core and the business platforms

18:58

around it, we believe we have a setupthat we can adjust to our adjusting

19:03

environments in a lot easier way. So it's very pragmatic what we do,hard to achieve, but in the long run,

19:10

it will get us a lot closer to ourdream of becoming the most, or the

19:15

best connected brewery in the world. That's great to hear.

19:18

So, as you're working in thesupply chain and brewery industry.

19:21

You might know that in the 1960s the MITdeveloped the so-called beer distribution

19:26

game as a management simulation. So participants have to take on theroles of a retailer or a wholesaler

19:33

distribution center or brewery. And the aim is to get crates ofbeer from brewery to the customer

19:40

as cost effectively as possible. And they have to deal with a lotof different problems like we've

19:45

seen it also in the real world. As said, as you're working inthe brewery industry, how

19:51

realistic is this simulation game? And are there some kind of parallelitieswhere you say, okay, this is something

19:58

that happens in the game and also in thereal world that we can just like take

20:04

the learnings from that simulation game?

20:07

Yeah, it's actually quite shockingas you go back more than 60 years

20:11

and you see something that's today'sreality is as relevant as it was then.

20:17

Going back to one of the earlierquestions, the volatility in the supply

20:20

chain has gone up so much that I thinkthat the beer distribution game is now

20:25

more realistic than ever because youwant to find your bottlenecks faster.

20:31

You will defined your problems faster. So you can actually create more of thatlean supply chain and that your throughput

20:37

is ongoing whilst your customers andconsumers change their minds and change

20:43

their behaviors in a lot faster way.

20:45

So I think every single elementof the game is still relevant

20:50

and even more relevant thanit was maybe 10, 20 years ago.

20:54

And this is for me is if youlook into technology that is

20:58

helping us to address that. Current systems are a lot moreadvanced than they were in the past.

21:04

They are able to forecast this iswhere ML, but also at one moment,

21:11

AI, I think it's too early for that,but that will start to play a role.

21:15

Some of our planning systems, we willbe implementing ML and AI models.

21:19

So we're doing that as we speak toaddress a number of these challenges

21:23

in your end-to-end value chain. So yeah, the game is relevant.

21:28

And with the current technology, I thinkwe can address the same challenges and

21:33

different challenges, but mainly a lotfaster than we could in the 1960s when you

21:38

would have a big mainframe that would, atone moment in time, churn out an outcome.

21:44

I think you can now do millionsof those outcomes a lot faster.

21:47

Which will lead to many, many scenariosthat you can then pick from, so you can

21:52

do a lot of that parallel calculation.

21:55

And then based on the end to end scenariosthat are calculated, you can actually

21:58

choose the best scenario at that momentin time from an end-to-end perspective.

22:04

Which is different what you would seein the 60s because you always end up

22:08

with a lot of manual effort, a littlebit of sub optimizing because it is so

22:12

hard to connect the entire value chain.

22:15

That for me is where technologymakes the biggest difference.

22:19

It's that rapid calculation of multiplescenarios pretty much in parallel.

22:24

We're not really yet at quantum computing,when that will be even more advanced.

22:28

But yeah, let's wait for anotherdecade for that to become mainstream.

22:31

I would be very happy to see what today'stechnologies can bring us already.

22:35

Yeah, that's great. Do you also see that using technologylike AI or GenAI will not just help

22:43

us, but maybe also, well, let's sayreduce some kind of work or make some

22:48

work obsolete in the supply chain area?

22:51

Without a doubt, it willhave a massive impact.

22:53

And, I think we don't know yetwhat the exact impact will be.

22:57

Jobs like mine, the amount of time Ispent on answering emails or creating

23:02

PowerPoint slides, you know, this iswhere co-pilot can already help on that.

23:07

Does that make my job better? I hope so.

23:10

Does it mean my job is no longer required?

23:13

I hope not. But yeah, you can see theseimpacts will be there.

23:17

Of course it will impact certainjobs that might no longer be needed.

23:21

It will also create other jobs.

23:24

It will also create jobs that we can sayare more meaningful, are challenging,

23:30

or more focusing on topics that areharder to achieve through technology.

23:34

But it is a game changer that Ithink we all don't know yet and that

23:39

for me is also the flip side of AIand same as on Generative AI is the

23:46

ethics around that because if youdon't watch out you will have one AI

23:50

answering my email sending that to myboss whose AI will answer his email.

23:55

You have two AIs talking to each otherand the conversation goes out of control.

23:59

Well, that's within the same company. But what if we deal with our customers?

24:03

What if we deal with our suppliers?

24:05

So where do we draw the line and how dowe make sure that we have a certain level

24:09

of control or maybe vetting of your AIs?

24:13

So there's a big debate,of course on that.

24:16

So I expect AI and everything withit, like it has done in the last

24:20

10, 20, 30, 40 years, the impactof technology has been massive.

24:25

We've always felt threatened by,Oh, now I'm no longer required.

24:29

But look at that, we have a massiveshortage in the marketplace of labor.

24:33

So we are short of people. So, so far, technology has never led to asituation that technology has taken over.

24:41

I don't think that with AI thatsuddenly will change, but it will be

24:46

a big challenge on how we're going toincorporated into the broader marketplace

24:52

and how do we make sure that we benefitfrom a global scale that not just AI

24:57

is highly relevant in parts of Europeor parts of North America, whilst in

25:03

other parts of the world that doesn'tapply because that is a situation that I

25:07

think would not be good for the planet. Exactly.

25:11

Hugo, well, believe it or not, we arealready coming to the end of the podcast

25:16

and the title is the future supply chain. Could you summarize in one or twosentences what the future supply

25:22

chain might look like and whatwe can expect in this new year?

25:27

If I would be able to predict the future,I think I would buy a lottery ticket

25:30

and go to a sunny beach somewhere,but let me give it a, an effort.

25:33

I think next year and also beyond, Ithink we will see a continuation and maybe

25:38

an acceleration of what we've seen so far. So volatility will remain highin different parts of the world.

25:44

Be it based on issues like we see inUkraine and Israel, but also potential

25:49

impact of elections in the UnitedStates, for example whatever the outcome

25:53

is that might impact a big part ofeconomies and political stability.

25:58

At the same end consumerswill continuously want

26:02

more and more innovations. Sustainability will continuouslybecome more important.

26:08

And AI will continuously becomemore of an opportunity and more of a

26:14

potential threat as we just discussed. So yeah, if we look into that for me, theend-to-end visibility of our value chain.

26:21

So not just the supply chain, theend-to-end value chain, that next

26:24

year will become absolutely critical.

26:27

And for that, we need to make sure that wehave the data and we have the technologies

26:32

to rapidly address all the issues thatcome from a consumer, a customer, or

26:39

a political and economical nature. That is, in a nutshell,what I expect into 2024.

26:45

And from a Heineken perspective, I thinkwe are taking massive steps towards

26:50

that, still have a long road to go. And with a lot of our great partners,I think we're in a pretty good state,

26:56

but yeah, it's always going to bea big question mark on what exactly

26:59

is going to happen in the future. Yes, it's like lookingthrough a crystal ball, right?

27:04

But at least you have the feelingfor it that you think, okay, this is

27:09

something that could happen or thatwill be, you can actually push something

27:14

into certain directions, right? Yeah, you can, uh, but you canonly prepare for the unknown.

27:22

So that is why I believe youneed to start to think in, hey.

27:25

What could impacts be so that you'reready for it whilst you don't know,

27:30

take the consumer as an example. We don't know the exactdevelopment of consumer demand.

27:36

Something completely disruptivemight happen into our industry.

27:41

How are we then going to makesure that we rapidly are ready

27:45

for that unknown disruption? I think that is the key elementthat's for us at Heineken, but I

27:51

think also for many other companies. Is the key into next year and years afteris getting ready for that unknown so that

27:58

you're able to counter it a lot better.

28:01

Yes. Well, Hugo, thank you somuch again for joining me.

28:06

It was super great to talk to youand to get more insights into also

28:10

Heineken and also digital transformationbackbone that you are doing right now.

28:15

And thank you all for listening. Please mark us as a favorite andyou can get regular updates and

28:20

information about the future episodes. Until next time from Hugo and I, thank youfor discussing the Future of Supply Chain.

From The Podcast

The Future of Supply Chain

The Future of Supply Chain podcast is a show hosted by Richard Howells, Sin To, and Nicole Smythe. The trio discusses hot topics, best practices, and the latest innovations to deliver a risk-resilient and sustainable supply chain. The show features interviews with experts from the world of supply chain, sustainability, and Industry 4.0, who will address the issues of today and tomorrow. This is an ideal podcast for supply chain, R&D, manufacturing, logistics, and operations executives to learn and share ideas and best practices with their peers.Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

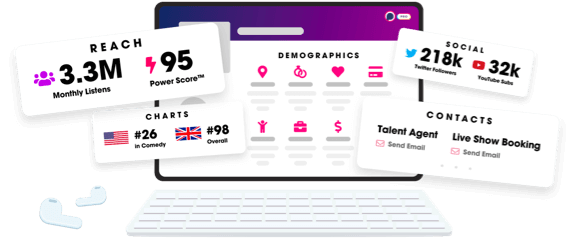

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us