Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:00

(Please note: transcript is AI generated) Zachary Cartwright [00:00:00]: I'm Zachary Cartwright. This is water and food. Today. My guest is Dr. Milda Embuscado, who is a distinguished scientist at McCormick and Company, located in Hunt Valley, Maryland. She received an outstanding Food Science award from Purdue University in 2016 and is an IFT fellow. Dr. Embuscado's focus is on materials and processing technology, including powder science and technology, isolation and extraction of flavor compounds from natural sources, flavor encapsulation, and food emulsions. Zachary Cartwright [00:00:29]: In her role, she routinely uses water activity measurements and moisture absorption isotherms to understand her ingredients and products and also bring new products to market faster. Let's hear what Dr. Milda Embuscado has to say on this episode of Water and Food. Hi, Milda. Thanks for being on the show today. We appreciate you being here. Milda Embuscado [00:00:48]: Thank you for inviting me, Zachary. Zachary Cartwright [00:00:52]: I've been looking forward to this for a long time. I know we've had to jump through a few hurdles to get here, but thanks for being here. So you're a distinguished scientist at McCormick and Company. What does that mean? What do you do there? Milda Embuscado [00:01:06]: Yeah, at McCormick, there are two ladders management ladder and technical ladder. So this was created by our previous science officer and to make the position more rewarding on the technical side. And so to follow up also the progress of the people under the technical ladder, he created the different steps to be able to achieve that. And on the technical ladder, actually, the highest is McCormick scientists, and distinguished scientists is only second to see. Zachary Cartwright [00:01:52]: And what do you have to do? How do you get to that next? Milda Embuscado [00:01:59]: You know, create projects that will be very beneficial to McCormick in terms of product that we put out there in the market. Zachary Cartwright [00:02:11]: I see. And you're mainly working on the product development and research development, or what category do you fall under? Milda Embuscado [00:02:19]: Yeah, actually, I am working both on product development on specialized products, and also I work with product developers on their different products that they would like to commercialize in the future. And this is where the powder science and technology comes in, because that's one of the area of the material science and process technology is very strong on background as far as science and technology is concerned and also the facilities that we use to enable us to test different products that will be successful in the market. Zachary Cartwright [00:03:03]: And how did you prepare for your role at McCormick? I see here that you have a PhD at Purdue, and I was just wondering if you could talk a little bit about your background and how you got to where you are today. Milda Embuscado [00:03:14]: Yes. So I did my PhD in food science at Purdue University in West Lafayette, Indiana. My area of specialization is actually food chemistry. I did postdoc in carbohydrate chemistry and also coupled with that, food processing engineering. So it's kind of combination, which is good because I understand the chemistry and the processing technology as well, as well as the chemical engineer, but at least I understand when they tell me about the processes that they're doing. Zachary Cartwright [00:03:54]: And once you finished your degree, you went on and you worked as a senior carbohydrate specialist, is that correct? Milda Embuscado [00:04:01]: Yes. So I stayed with the Whistler Center for Carbohydrate Chemistry, and that's where I have the opportunity to work with one of the world renowned carbohydrate chemists, dr. James B. Miller. And then after that, I was promoted to research scientist at the Whistler Center. Then thinking about the application and the commercial side and industrial application of what I learned from the Whistler Center and from Purdue, I was encouraged to go to the industry, and that is where the Seristar USA comes in. I worked there as a carbohydrate specialist for three years before moving on to McCormick. So it's a starch company. Milda Embuscado [00:04:51]: We handle maltodextrine, corn syrup, sugars, and all the different starches that you can think of. Zachary Cartwright [00:05:00]: All right, it looks like you've been at McCormick for about 23 or maybe 24 years at this point. Milda. What keeps you coming back to work? Why are you excited to work there? Milda Embuscado [00:05:11]: Yeah, actually 23 years last May. R and D is a really very challenging area to work in. There's always something new, and that makes me come back every time there's new challenges. We need to think about innovation and future technology that will be applicable so that the company will progress. And in addition to that, working with the product developers is also enhancing our capabilities individually. As professional, they always have challenges, and one of those, of course, is powder science and technology. How can we bring this particular product to the market without issues? And of course, those issues never end because most of our products are very complex, maybe the minimum of ten different ingredients to as much as 31 or 35 ingredients in that seasoning blend. So each of those ingredients will pose certain issues, especially the different plants for our customers. Milda Embuscado [00:06:23]: They have different equipment, different environment. One area is probably on the cooler side of the US. And others will be in the high humidity, high temperature setting with old equipment that each of our seasoning blend should work on. Zachary Cartwright [00:06:45]: And what are some of the other, maybe, specific challenges that you have to overcome? It sounds like you've mentioned a few. Having to make products with lots of ingredients and thinking about how those ingredients interact or shipping products to different regions of the country and having to worry about different environments. Are there any other maybe, challenges or issues that you would add to that list? Milda Embuscado [00:07:06]: Yeah, we need to zero in, actually what the customer have in terms of equipment and how they apply the seasoning blend. One particular example is we created this really good seasoning blend with lot of chili pepper in it and of course, some organic acids and sugars. And actually, they don't stick well on the chips. They stick more on the equipment. And so we need to resolve that and we need to resolve that quickly after the first trial because the expectation of our customer is for it to work in all their plants and in 24 hours that's the first testing actually and sometimes longer. Zachary Cartwright [00:07:56]: And how do you use water activity measurements to overcome some of these challenges? How does water activity, why is it important for these types of products that you work on? Milda Embuscado [00:08:06]: Yeah, first of all, we need to know the water activity of all the ingredients in that seasoning blend and they ranges from moisture from five or lower to sometimes 15%. And the moisture content that's going to tell us the whole story. We need to know the water activity because that is very important in how the moisture transfer from one ingredient to the other component of the seasoning blend. So typically if you have organic acids and sugar, then you need to watch out the final or the calibrated water activity of the seasoning blend because you cannot push everything to 0.2, for example, because the other ingredients have high water activity, especially the spices and herbs which has undergone steam sterilization. And that actually creates a big problem as far as stability during shelf life, during shipping, and also at the customer's plant. So we need to know the water activity of all the raw materials. We need to know the equilibrated water activity, which of course can be given to us by the VSA in one of those, the menu that we can input all the water activity and then we come up with, the software itself will come up with the equilibrated water activity that's actually very useful. Instead of waiting for probably two to three days until the seasoning blend reaches the equilibration point, we have the VSA to be able to do that for. Zachary Cartwright [00:09:48]: And just to kind of summarize, so it sounds like you're using water activity to check your incoming ingredients, to check once your products have reached equilibrium and then maybe even to look at water activity during shelf life. And then you just mentioned the AQUILAB vapor sorption analyzer or the VSA, you would be considered a power user of this technology. And you're using dynamic dew point isotherms, is that correct or what type of isotherm are you using in order to predict what the equilibrium will be? Milda Embuscado [00:10:19]: Yeah, for most of our seasoning blends, or probably, I should say for all our seasoning blends, especially the newly formulated products, we use equipment to test for the critical water activity so that we know points of failure for example. And with that we needed to add other ingredients that will increase the critical water activity at our customers plant. One particular case that we did resolve quite quickly is in those encapsulated products, using gum arabic versus a starch actually makes a big difference as far as the critical water activity is concerned. And so without VSA, we won't be able to know that. We will just be saying, oh, it failed because the product is really very hygroscopic. But with the VSA, we were able to pinpoint what raw material is actually doing that and what are the solutions that it can offer when we reformulated the seasoning blend. Zachary Cartwright [00:11:30]: So if you weren't using the VSA and if you weren't using dynamic dew point isotherms, would you be using like a guess and check method? Or how would you even go about finding that critical point if you weren't using this technology? Milda Embuscado [00:11:44]: Yeah, the old method, of course, is having all those desiccators, right, and then waiting until it calibrates with the relative humidity of the desiccators containing saturated salt solutions. And that will take forever. And sometimes you cannot really pinpoint the exact critical value of the water activity because it's difficult. Sometimes it's past that already and you observe, oh, it caked, or it is already melting at that point. So even though it is something that those people don't have, the equipment can use it. It's not very efficient. It's not very accurate as well. Zachary Cartwright [00:12:29]: So once you determine that critical point, are you using it to set a spec? And then you tell that to your production team so that you can avoid some of these challenges that you mentioned earlier or what's kind of the next step. Once you identify that point, how do your other teammates or other members at McCormick use that information to make sure as a whole, your team is successful with producing that product? Milda Embuscado [00:12:53]: Yeah, what we do is go back to the drawing board. We actually evaluate all the ingredients there. We formulated a database already, so there is some old raw materials that we can deduce what it's doing to the seasoning blend, but for the new ones or something that we have to use to replace an old ingredient, then we have to really evaluate all those ingredients in closer detail. Zachary Cartwright [00:13:28]: I see. And if you were working at maybe another spice company, if you didn't have this approach, maybe you can talk about how having this technology has improved your experience or being able to make products quicker and bring them to market faster. What were you doing before this technology and how has it improved your experience in your current role? Milda Embuscado [00:13:53]: Yeah, actually before we bought the VSA, we have an old equipment that we use came from in Florida. It does give you the moisture absorption isotherm, but it doesn't have all those different parameters that you can measure using your software. So we kind of struggle with that particular equipment and technology and later on they were not able to update their software anyway, so we stopped using it altogether. I think it will be impossible with other equipment to do what DSA is doing. So it's more like a guessing mean. It's not that exact number that it comes up with. Right. So you need to deduce based on the moisture absorption isotherm, apply some more mathematical equation to be able to come up with those critical parameters. Zachary Cartwright [00:14:58]: And I think you made some really good points there. And this is often what I talk to people about, the VSA. Two things that really make it stand out are the patented dynamic Dew point isotherm. It's a really high resolution isotherm that you can make very quickly that can help you identify those critical points. And also the software, I mean, there are other isotherm generators, but the software we've spent a lot of time developing so that you can take your data and turn it into some of the different solutions that you've mentioned, like finding the equilibrium point or finding a critical point and so on. So we've tried to make that really user friendly, and I'm glad that it's been able to help your team. Are there any other new products or new formulations that you're excited about that you've been working on that you're able to talk to us about today? Milda Embuscado [00:15:45]: Oh, yeah, we have a lot of product developers in our building, and so they develop products almost every day. In some of those, the raw materials are known. So it's not a challenge to really come up with a stable product. But of course, the customers sometimes request something that is really different from what they are used to formulating. And so those are the ones that we focus on so that we'll make sure that it will be stable and will not fail at our customers plant. Zachary Cartwright [00:16:22]: And are you currently trying to fill any roles? Are you looking for new product developers or anybody else to join your team at this time? Milda Embuscado [00:16:31]: Not at this .1. Of the very good things about McCormick is the turnover is very what do you call this? Low. Yeah, people stay for a long time. Like myself, I thought I'd be here only for a few years and then move on. Right. So it's usual that the product developers, scientists, and engineers stay here for 1015 years and sometimes in some cases probably as long as 30 years. It's a very good environment and people are really very professional. They help you advance your career in the process, and we help each other to accomplish what we need to accomplish for the company. Zachary Cartwright [00:17:26]: And what is next for you, either at McCormick or maybe in your personal life? What are you looking forward to maybe this next year or looking ahead? Milda Embuscado [00:17:36]: Yeah, actually we've started a really more goal oriented program in terms of powder science and technology. So we're creating database of all the raw materials that are new to McCormick, all those natural sweeteners that we need to characterize so we can use them more intelligently in some of our seasoning blends and food powders. In addition to that, we would like to streamline our testing process in terms of powder flowability, functional properties like adhesion to chips, for example, or different matrices we would also like to be abreast on the new packaging materials, especially those which are sustainable in the market. And so there's a lot of things that we would like to focus on as far as food powders are concerned. And of course, VSA will always play a major part in that because it's a very useful equipment for all the products that we produce in dry formats. Zachary Cartwright [00:18:55]: Well, it sounds like you have a busy schedule ahead of you and still lots of things to work on, but like you said earlier, that's what keeps you coming back and working for McCormick. So we're excited to keep supporting you and see how you use your Isotherms and you're able to overcome some of those challenges. So I just want to say thank you so much, Milda. Again, we've been looking forward to this for quite a while and I'm really glad to see how you've been able to use our technology and approach all of these different products that you work on. Is there anything I missed, anything else that you would like to add to this episode? Anything you wish I would have asked or something you'd like to end on? Milda Embuscado [00:19:34]: Yeah, actually the area that I worked on at Purdue helped me very much in learning all this caking and adhesion and all those problems that I encountered in food Powder and seasoning Blend and all the equipment that actually we got from the meter group, starting with the water activity meters. Actually, when I came to McCormick, we still have that very old water activity meter in which you calibrate by adjusting the screw so that it will be exactly that was really good. And after that, we got a few more, the new ones, including the TDL two and of course, the VSA. So thank you very much for all your help and this will be really a very good partnership between the two companies, our two companies in advancing powder science and technology. Zachary Cartwright [00:20:35]: Well, we're looking forward to continuing that partnership and working with you. So thanks again, Milda. We really appreciate having you here and maybe sometime down the road we'll check in with you and see what's new with you and your team and how you're using those technologies. Milda Embuscado [00:20:50]: Thank you. Zachary. Zachary Cartwright [00:20:52]: I'm Zachary Cartwright. This is water and food. Find this podcast on Apple itunes, Spotify, or wherever you listen to podcasts.

From The Podcast

The Drip by AQUALAB (formerly Water In Food)

Welcome to The Drip (formerly Water in Food), where we keep your mind hydrated with some science, music, and a mantra. I'm your host, Zachary Cartwright, lead food scientist at AQUALAB by AddiumHosted by Zachary Cartwright, Ph.D.Lead FOOD Scientist at AQUALABhttps://www.aqualab.com/Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

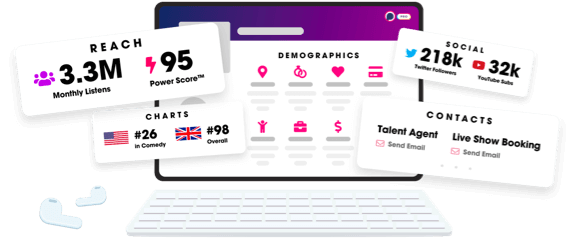

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us