Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:10

Hello, and welcome to another

0:12

episode of the Odd Lots Podcast.

0:15

I'm Joe Wisenthal and I'm

0:17

Tracy Alloway. Tracy,

0:20

I know it's early morning time

0:22

in Hong Kong where you are right now. But did

0:24

you hear the big news while you were sleeping? Um?

0:29

Well, I'm trying to think. I guess I didn't.

0:31

What was the big news while I was sleeping? Maybe

0:34

maybe you saw it before you went to bed, just that they freed

0:36

the ship. Oh yeah, so maybe

0:38

that happened before you fell asleep. It did that

0:40

happen during the working day in Asia? They

0:42

got it floating? Um, and then

0:44

they got it I guess more floating

0:47

or more free. Yeah, it's

0:49

good news for global supply chains,

0:53

global factories, retail

0:55

outlets. Everyone breathing a big

0:57

sigh of relief as the were

1:00

given ship that was stuck in the

1:02

Suez for six days. As

1:04

of right now we're recording this March New

1:08

York time, seven pm New York time has

1:10

been Uh, it's been freed. It's floating again.

1:13

The thing that I really loved about, you

1:15

know, this very special week where

1:18

we were all focused on this one container

1:20

ship that was stuck in a Canal was

1:22

that, first of all,

1:24

everyone suddenly took an interest in global

1:27

shipping and transport and global

1:29

trade, which is something that usually

1:31

people don't necessarily think

1:34

of that much, or at least they don't think about how

1:36

stuff actually gets to them. People think

1:38

about global trade, but not necessarily

1:40

the infrastructure and the industry that kind

1:43

of underpins it. So last week

1:45

was a really good one for everyone to sort of sit

1:47

back and consider how

1:49

globalization actually works and how the

1:52

flow of all these goods is actually

1:54

affected. Absolutely.

1:56

Also, like everyone becomes like a container

1:59

ship expert like overnight. But

2:01

the good news is, like you and I are like kind

2:04

of experts because we've actually talked

2:06

to one before. Hey, I have read

2:08

two books on shipping, so you

2:10

know, I feel like I'm I'm firmly up

2:12

there as an expert. I'm joking

2:14

obviously, but fair enough, but I

2:17

am, you know, the next best thing, because

2:19

we did an episode back in January

2:21

where we talked about container ships,

2:24

and so that turned out to be very,

2:26

um, very auspicious

2:28

because then I knew like two or three facts

2:30

that I was able to like put in tweets

2:32

and stuff like that, which is, you know, more

2:34

than I would have otherwise been able to. Well, look, it

2:36

was a great episode, and there are multiple issues

2:39

affecting shipping at the moment. So we have

2:41

the gridlock in traffic because

2:44

of the coronavirus crisis,

2:46

and also the sort of changes

2:48

in the direction of global

2:50

trade, so you know, stuff getting really

2:52

snarled between China and the US because

2:54

lots of people in America are just buying more

2:57

and more things during the pandemic.

3:00

But then we also have a separate issue,

3:02

which is that ships are

3:04

so freaking big a they

3:07

get stuck in canals and be they

3:10

also contribute to um

3:12

that global snarling of of shipping

3:14

traffic instead of actually alleviating it.

3:16

Exactly right. So Beck in January

3:19

we talked about the high cost of

3:21

shipping these days. We spoke with Mark

3:23

Levinson, who is the author of The

3:25

Box, famous book The Box How the shipping

3:28

container made the world smaller and the

3:30

world economy bigger, And he said something

3:32

on that episode which was very

3:35

uspicious or very very timely,

3:38

which was that a big part of the problem was

3:41

that ships are just massive these days

3:43

and that creates its own problems

3:46

for the logistical system of the globe. And

3:48

then of course, one of the biggest ships in the world

3:51

ended up jamming the Suez and that was

3:53

sort of a freak accident. There was

3:55

a sandstorm, some really great reporting

3:57

on exactly how it went down. Nonetheless,

4:00

it was sort of an example of what he

4:02

was talking about, which is that these gigantic

4:04

ships are bigger

4:06

and not you know, the infrastructure for shipping

4:09

is not necessarily optimized for ships

4:11

these large Yeah, I think

4:13

that's exactly right. So I'm very excited

4:15

we have Mark back on the

4:18

podcast. Everyone loved the last one, and this

4:20

time we're going to focus just on this

4:23

question, the problem

4:25

with really big ships. So Mark,

4:27

thank you for coming back on Odd Lots. Hey,

4:30

Joe, glad to be with you. Tracy, good to be with you

4:32

tonight. So the sue is

4:34

is uh is free again? Um,

4:37

the ever given has been floated. It went down

4:39

the canal. Nonetheless, as you

4:41

pointed out back in January, large

4:44

ships are problems. So let's just start with the

4:46

question of when we talk about

4:48

a large ship. I mean, all shipping containers

4:50

ships are large, But when we talk about a large

4:52

ship, what are we really talking about here?

4:55

Well, shipping guys use

4:59

the term t e u t EU

5:02

means twenty foot equivalent units.

5:05

UH. The size container you see

5:07

on the back of the truck when you're driving down a highway

5:10

is typically about forty ft. So

5:13

if you take the number of t e u s

5:15

and divide by two, that tells

5:17

you how many truckloads are on the

5:19

ship. So we're talking

5:22

here about a vessel that

5:25

was roughly twenty thousand t e

5:27

u s. In other words, it was capable of holding

5:30

as much cargo as roughly ten

5:32

thousand over the road trucks. This

5:35

is not the biggest vessel out there on the

5:37

seat. The biggest that

5:39

are afloat now in the container

5:42

ship line can hold two

5:44

thousand eu s, or as much cargo

5:46

as twelve thousand trucks. So

5:49

that's a lot of freight on a single vessel.

5:52

So talk to us exactly about the economics

5:55

driving the shift towards bigger

5:57

ships. So you know, it's not like people

5:59

woke up one day and said they're going to build

6:01

big ships for the sake of it um or at

6:03

least maybe some people did, but not

6:05

everyone. There were supposed to be efficiencies

6:08

that were targeted. Right the

6:11

first modern container ship voyage

6:13

was back in nineteen fifty six, and

6:17

the ship that made that trip was

6:19

called the Ideal X and it carried

6:21

fifty eight containers. Go

6:24

from fifty eight to twelve thousand,

6:27

and you can see the sort of growth that's gone

6:29

on in this industry. Most

6:31

of that time, ships got

6:34

bigger, small step by

6:36

small step, okay they

6:38

they the next generation added

6:41

a few hundred more containers at

6:43

best, and so ships were getting

6:45

steadily larger, but moderately

6:48

so. And then

6:51

in two thousand three,

6:54

the Shipline Merisk, which is based in Denmark,

6:57

as I think everyone knows by now, a

6:59

decide did a that it

7:01

was in danger of running out of capacity,

7:03

so it needed some big ships and

7:06

be that it really wanted

7:09

to get a jump on everybody

7:11

else by having much bigger ships, and

7:14

so it commissioned a series of seven

7:16

vessels. These

7:19

ships, it turned out,

7:22

we're six larger than any

7:24

other ships that were on the ocean at that point.

7:27

That's not what had been advertised, but that's

7:30

what turned out to be the case. So they

7:32

were just hugely a

7:34

large compared to anything else that was

7:36

at sea or in the order books

7:38

at this point in time. Those mask

7:41

ships, the first was called the MA Marisk came

7:43

online starting in two thousand six.

7:46

These very large ships. M

7:49

Marsk was capable of carrying about fifteen

7:52

thousand Eu s in other words, truck

7:55

size containers, and assuming

7:58

that she was full, could

8:00

do that much much more cheaply

8:03

than any of the other ships being used

8:06

in the industry. And so the

8:08

competitors looked at this and said,

8:12

we got to do something too. We've

8:14

got to build ships at

8:16

least as big as the MM Marisk, or we're going

8:18

to have higher costs. And

8:22

yet they were faced with a dilemma, which

8:24

was if they built

8:27

higher, bigger ships, and everybody else

8:29

built bigger ships, then there was going to

8:31

be a whole lot of capacity coming onto

8:33

the market, and that was going to cause a problem

8:35

too. Most of the ship lines

8:37

ended up building bigger ships, and

8:40

you started to see around.

8:43

You started to see ships of seventeen

8:46

eighteen thousand Eu s going

8:48

on. And now they've

8:50

been up into the high teams and then

8:52

into the twenties, such as the one that

8:54

was just stranded in the Suez Canal.

8:57

And now we're talking do

9:01

they save money, Well,

9:05

they save money on the

9:07

ocean leg of the

9:10

transport. If the ship

9:13

is full or close to full. For

9:16

most of the past decade, the ship lines had

9:18

this problem that there wasn't all that much cargo.

9:20

They had really overestimated the growth in international

9:23

trade, and so they were

9:25

running these enormous ships

9:27

around the oceans half empty, and

9:30

that was a recipe for losing a lot of money.

9:32

Many ship lines went bust, others

9:34

were forced to merge, and

9:37

the pandemic kind of bailed

9:39

out the shipping industry. When Americans

9:42

couldn't take vacations and Europeans couldn't

9:44

take vacations, they couldn't go out to the restaurant,

9:46

they couldn't go to a concert, couldn't go to the theater,

9:49

they started spending their money on stuff,

9:52

and all of a sudden, the ships got

9:54

full of factories in Asia revved up

9:56

and all this cargo was was

9:58

filling these vessels really for the first time. So

10:18

going back to um the

10:21

dawn of the really big ships here,

10:23

I mean, it's interesting this sort of I don't

10:25

know, maybe it's it's a game theory because

10:27

everyone wants to have the cheapest shipping

10:30

and so okay, everyone feels they need to compete in larger

10:32

and larger more efficient ships. On the other

10:34

hand, that creates all this inventory and a problem.

10:37

But I guess, like was it a problem?

10:40

Is that was the thinking back and like saying, like

10:42

two thousand, two thousand six that like,

10:45

well, globalization just keeps getting

10:47

bigger, world trade keeps growing, There's

10:50

this big commodities boom going on. China

10:52

is buying stuff voraciously. So essentially,

10:55

yeah, it creates some risks, but ultimately,

10:58

at least back then, it looked like volume

11:00

would just sort of keep growing forever and that would take

11:03

care of any of the capacity the

11:05

capacity build up. Yes, absolutely,

11:07

Joe. The expectation was that international

11:10

trade would continue to boom.

11:12

From the late nighties

11:15

until the

11:17

two thousand seven eight international

11:20

trade grew more

11:22

than twice as fast as the world economy, and

11:25

the expectation was that that was going to continue,

11:27

and that there was going to be a need

11:30

for shipping capacity to handle all

11:32

of these exports from

11:34

Asia that were expected to come. And

11:37

of course after

11:39

the financial crisis, trade

11:42

did not pick up as it always had

11:44

after recession, so there were a lot of

11:47

half empty ships sailing around. So

11:50

one thing I've wondered is if we assumed

11:53

the counter factual, Like, let's say that global trade

11:56

had boomed, would the

11:58

mega ships be more efficient

12:00

or would there still be issues

12:03

with, for instance, their flexibility and

12:06

their ability to adapt to

12:08

changing trade routes, changing demand,

12:10

and things like that. If

12:13

world trade had continued to boom,

12:16

there would be a couple of things that would be different

12:18

now. One would be that

12:21

there would not have been a ton of container shipping

12:23

companies going out of business, so

12:26

there would be a lot more competition in the industry.

12:29

Given the number of firms that have gone out of business

12:32

and alliances between the surviving

12:34

shiplines, there are really only

12:36

three groups that dominate this

12:39

industry now, so it's somewhat of an olegopoly,

12:42

and that would have been less likely to happen

12:45

had a world trade remained

12:47

a robust The other

12:49

thing would be that shiplines would

12:52

have made some money, and they

12:54

might have behaved quite differently from from

12:56

the way that they ended up behaving,

12:59

but the landside problems

13:01

would not have gone away. What you're

13:04

pointing to is the

13:06

fact that the ship lines really

13:09

ordered these huge vessels because

13:11

they thought they were good for themselves. They

13:14

didn't really pay much attention at all

13:17

to the whole goods transport system.

13:19

They were not asking the question, well, what

13:21

happens when these show up at

13:24

the container terminal? Is the terminal

13:26

able to handle them? Will the

13:29

railroads be able to get enough trains in and

13:31

out? Will truckers be able to handle all

13:33

these boxes? Will the harbors be

13:35

deep enough that we can sail these ships in?

13:37

In the first place, those sorts of questions

13:40

really didn't get enough consideration.

13:42

And I think that even had trade

13:45

remained more robust than it proved

13:47

to be, these problems

13:50

with the freight transport system would

13:52

have developed because the

13:55

container ship lines said, here, we've got

13:57

this thing, which is good for us. You guys,

13:59

you worts, you railroads, you

14:02

truckers, you guys deal with this. So

14:04

this was what you brought up in our last conversation,

14:07

the sort of bottlenecks that have emerged

14:10

because of the size of the ships.

14:12

So let's go into that a little bit further,

14:15

um a walk through

14:17

specifically how the size

14:20

of the ships are I don't know if incompatible

14:22

is the right word, but problematic for the ports

14:24

and the sort of land based shipping

14:27

movement. And why didn't the

14:30

shipping companies foresee

14:32

this sort of like seemingly obvious thing like

14:34

if you have a plug, you want to make sure it fits on the outlet.

14:37

Why was this sort of not on their radar?

14:39

Well, I went into the second half of that first

14:42

Okay, sure, the shipping lines pretty

14:44

much took the attitude that ports,

14:46

it's your problem to deal with this. Railroads,

14:49

we're bringing you the cargo. You figure out how to get

14:51

it out of the port. Okay. It was

14:53

their attitude that there in the shipping business

14:56

and everybody else who is part of the logistics

14:58

system ought to just

15:00

deal with what's best for them.

15:02

So that's where where that went. I

15:06

think in terms of

15:09

the challenges posed by these very

15:11

large ships. Let me just give you a couple of examples.

15:14

These mega ships, these ones that hold

15:17

twenty thousand those

15:21

they are not longer than the ships that preceded

15:24

them to handle

15:26

all this cargo, they're

15:29

wider. Ships have grown

15:31

wider. Well, think

15:33

about how the cargo is typically moved on and

15:36

off a container ship. The container

15:38

ship pulls up to a wharf. There

15:41

are cranes alongside

15:43

the vessel, and each of these cranes

15:46

lifts containers off the vessel, puts

15:49

them onto a little carrier that's on

15:52

the ground. The carrier takes the container

15:55

away, and another carrier brings an outbound

15:57

container that goes onto the ship. Well,

16:01

since the ships are not longer than their

16:03

predecessors, there's no room for additional

16:06

cranes alongside the ship. But

16:08

since the ships are wider, it

16:10

takes longer each time a crane

16:13

reaches out with a container and

16:15

takes the container over to the far side of the

16:17

ship. So it takes an additional

16:20

few seconds to lift the average

16:22

container off the ship, and it

16:24

takes an additional few seconds to put

16:26

the average container onto the ship.

16:29

That may not sound like much, but

16:32

you're multiplying these few seconds

16:34

times thousands upon thousands of containers,

16:37

and all of a sudden, you're delaying the vessel. Okay,

16:39

it's it's stuck in port for longer

16:41

than it wants to be stuck in port

16:44

because they can't get the ship

16:47

discharged and reloaded in time, so

16:50

the cargo is delayed. There

16:53

have been a numerous

16:56

examples where ships left

16:58

China late, late late.

17:01

At some points a thirty

17:03

or thirty of the vessels leaving

17:05

China have been behind schedule. There

17:08

have been sailings canceled

17:10

because a ship couldn't complete its

17:12

sailing in time to do the next sailing. And

17:17

these are a result of the difficulty

17:20

aloading the ships and also

17:22

of the fact that these vessels were built

17:25

to steam slowly. In

17:27

previous iterations, container ships

17:30

were able to travel somewhat faster. It

17:33

was decided by the folks who designed these

17:35

megaships that they should

17:37

steam slowly, in part because

17:40

that saves money. They burn

17:42

less fuel, certainly less fuel

17:44

per container, and second, they

17:47

produce less greenhouse gassing missions

17:49

because the greenhouse gassing missions come from burning

17:51

fuel. So these slow vessels

17:53

are environmentally better and

17:56

and they don't waste energy. That's

17:58

all well and good, but what it means is that once they

18:00

fall behind schedule, they can't catch up

18:02

again. They can't go faster to make up the

18:05

time that perhaps was lost in port. So

18:07

there are a couple of examples of how these

18:11

very large ships really have exacerbated

18:14

the problems in supply chains. They

18:16

have a lot of trouble just delivering the goods on time.

18:19

So you mentioned this idea of

18:21

the ships getting wider, and I suppose that's

18:23

our our queue to talk about the canal.

18:26

But I mean talk to us

18:28

about how going down the Suez Canal

18:31

usually works, and whether

18:34

or not that process has become more difficult

18:37

as ships got larger. I

18:39

don't want to pretend that I'm an expert on the hydrology

18:43

of the Suez Canal, because I'm most definitely

18:45

not here. Um the Suez

18:48

Canal was dredged

18:51

to make it deeper for these very large ships

18:53

and for other very large ships, just

18:55

as many harbors have been

18:58

dredged to enable these large

19:00

ships to go through. The

19:02

vessel that was grounded in the Suez

19:05

Canal, they ever given, required

19:08

seventeen and a half meters of water just

19:11

about fifty two ft between

19:13

the water line and the bottom of the vessel.

19:16

Okay, so that's a lot of water. They need

19:18

a very deep the ship needs a very deep channel

19:21

to steam in, and

19:23

if the ship gets forced out

19:25

of that channel for whatever reason, there's

19:28

a lot of potential for bad things to happen. That's

19:31

true in a harbor. That's also true in

19:33

a canal. The channel

19:36

is not that wide, and sometimes events

19:38

occur. You do have winds

19:40

that can blow up

19:42

against the vessel. Remember,

19:46

a ship like this is a quarter

19:48

mile long. It has nine

19:50

or ten layers of containers

19:53

stacked on its deck in addition

19:55

to the containers below deck, so

19:58

ten layers of contained. Each

20:00

container says eight ft high,

20:03

that's eighty feet above the deck and

20:06

a quarter mile long, and it's like a wall.

20:10

So if there's a really strong gust of wind,

20:13

it's one more source of pressure on the ship.

20:15

It can can push the ship, and

20:17

container ships have had problems with this in

20:20

the past. I think the size makes the

20:22

situation a little bit worse. This particular

20:25

container ship was actually involved

20:28

in an accident in Hamburg, Germany,

20:30

a few years ago. The ship's only

20:32

three years old, so a few years ago means too, I

20:35

believe, when

20:37

again the ship was blown a little

20:39

bit and it ran up against

20:42

a ferry boat. And accidents

20:45

happen sometimes. But the

20:47

large size of the vessel

20:50

of this sum this magnitude, and

20:53

the large amount of containers stacked

20:55

on the deck, I think makes

20:58

perhaps for a smaller margin of error. Zooming

21:15

back out to this sort of global

21:18

situation that we have right now, and it's ongoing

21:20

and there's all these delays in every retailer.

21:23

Last quarter, H talked about

21:25

that, how does uh, you

21:27

know this this phenomenon of super large

21:29

ships creating tension at the ports. Obviously

21:31

it's been going on for a while. But how

21:34

in this current environment

21:37

are they uh you know, the sort

21:39

of mismatch between the capabilities of the ports,

21:41

the transportation system, and the size of the ships.

21:44

How is that exacerbating the

21:46

current issues that we're seeing with trade

21:48

all over the place. Well, the problems

21:51

in the ports, I think tend to slow

21:53

down. Once the ship

21:56

gets there, it has to unload, right, has

21:59

to discharge its cargo. We've certainly

22:01

had some complaints in the United

22:03

States that the

22:05

ships were not waiting to be fully

22:08

loaded. They wanted to get

22:10

back to China, and they wanted to take empty

22:12

containers with them back to China just

22:15

so there could be more Chinese exports. Um.

22:17

There have been complaints from the US farm sector

22:21

that farm goods that normally

22:23

moving containers haven't

22:26

been accommodated. Typically, the

22:29

westbound freight on the Pacific moves

22:31

at a much lower rate because

22:33

most of the cargo is coming east from Asia

22:35

to the United States, and so these

22:37

guys are looking to send containers of soybeans

22:40

or of meat

22:43

products or other things to

22:45

Asia, and they're complaining they can't

22:47

get enough containers because

22:51

as a result of the mess in the

22:53

ports, the ships just want to get out of there and

22:55

won't wait for the outbound containers. So

22:58

that is one example of the sorts

23:01

of problems that people are

23:03

seeing when you have an event

23:06

like happened in the Suez

23:08

Canal. Well,

23:10

some vessels decided to go around

23:13

Africa to to get

23:16

between Asia and Europe.

23:19

Well that's a longer trip, Okay, that adds

23:21

two to three weeks to the chip trip

23:23

between Asian and northern Europe. If

23:26

each trip is going to take a longer period

23:28

of time, that means the vessel can't make as many

23:31

trips over the course of a year, which means it can't

23:33

carry as much cargo over the course of a year.

23:35

And so you can see that there's going to be even more

23:37

pressure for a while, at least on

23:41

the supply chain. So

23:44

we talked a little bit about this in the intro. But

23:47

one of the great things about

23:49

this whole um chipping drama

23:52

has been that people are talking about

23:55

these transport issues in a way that they

23:57

don't usually talk about. And you

23:59

may the point in your book that

24:02

the whole field of economics

24:04

kind of persistently

24:06

underestimates or ignores

24:09

the costs embedded in transport,

24:11

like the idea that there might actually be frictions.

24:14

When people talk about competitive advantage, they

24:16

usually talk about friction lists transactions.

24:19

Um. And I think you even cite the the

24:21

old example of you know, England versus

24:24

Portugal. The economists

24:26

who came up with that never actually took into account

24:28

transport costs when they said that, you know, it

24:31

might be cheaper for England to do this and for Portugal

24:33

to do this than they can just trade with each other. Do

24:36

you think the situation in global

24:38

shipping, the fact that we were all absolutely

24:41

fascinated by the ever given for

24:43

the past week, do you think that's going to change

24:45

that at all? Our people going to be more

24:48

focused on the frictions

24:50

caused by global transport or involved

24:53

in global transport because of these

24:55

issues. Absolutely.

24:58

And that's a wonderful opportunity to give

25:00

a shout out to my latest book which is called

25:03

Outside the Box. It talks

25:05

about these problems with supply chains

25:08

and it explains why businesses

25:12

that built these long supply chains systematically

25:14

underestimated the risk. Okay,

25:17

they made decisions about where to produce

25:19

things, typically in Asia, by

25:21

looking at production costs and transport

25:24

costs, and they didn't pencil in

25:26

the cost if, say the goods don't arrive

25:28

on time, well, that

25:30

can be a very significant cost. And

25:33

when that happens, then all

25:36

of the money that you saved on production may

25:39

not turn out to be such a great deal. So

25:42

I think we've seen a lot of companies now begin

25:44

to reassess whether these

25:47

supply chains makes sense

25:50

constructed as the way they have been. We've

25:52

seen in the United States,

25:54

which is the place where we've got the best data

25:56

on this, you've seen a lot of companies

25:59

keep more infantor than they used to. Right,

26:01

it used to be that companies didn't want

26:04

inventory. Everything was going to be just in time.

26:06

Inventory is wasteful. Well,

26:08

inventory is insurance, right. Inventory

26:11

gives you something to sell in case your next

26:13

delivery doesn't make it on time. So,

26:15

even though there's a cost, firms have been keeping

26:19

more inventory. Firms have been

26:21

looking at multiple production locations

26:23

rather than having everything made in some big

26:26

factory. Yes,

26:28

the big factory might give you great economies

26:30

of scale, but if there happens to be

26:33

a fire at the factory, or an earthquake

26:36

or if there's a transport disruption and route,

26:39

all those economies of scale aren't going to have help

26:41

and and so you really need an

26:43

alternative source of production.

26:46

And firms have been looking at these things. They've been

26:48

going for redundancy. There's

26:51

a lot of interest now and resilience. It's

26:53

actually a hard thing for a manufacturer

26:55

to do, but we've been

26:57

seeing a lot of attention to it. And that was even

27:00

for the forgiven was rounded

27:02

in the suite. Uh.

27:05

Mark, that was great. That's exactly you've

27:07

filled in a bunch of gaps for us and sort

27:09

of our understanding of this. And really appreciate

27:12

you coming back on oddline. Well,

27:14

it's been delightful to be with you. Thank

27:17

you very much for having me. Thanks so much,

27:19

Mark. Thanks Mark, that was great. I

27:38

found that very helpful, Tracy. I

27:40

mean I sort of had some sense

27:42

that the the size of

27:44

the ships was creating specific problems

27:47

at the ports. But his example

27:49

about like the crane, you can't put more

27:52

cranes because um not

27:54

any longer, but that they have to reach further into the

27:56

ship, but that takes a few more seconds

27:58

and that ends up like that really started to help

28:00

like crystallize the issue for me. Yeah,

28:03

the great thing about talking to Marcus he brings

28:05

this fantastic economics perspective

28:08

to global shipping, which I think,

28:10

um, you know, not everyone does. But

28:13

also the point about how building

28:15

these massive ships maybe

28:18

could have resulted in more efficiencies

28:20

at sea had global trade actually picked

28:22

up, but the bottleneck was always

28:24

going to be on the port side when you're

28:26

loaning and unlaning stuff. And the

28:29

irony there, of course, is that the whole

28:31

reason container shipping was invented was

28:33

to try to minimize costs

28:36

on the port side. So you used to have, you

28:38

know, hundreds of laborers

28:41

who would be unloading and loading

28:43

these boxes by hand, and they'd all be sort of

28:45

individually wrapped or everything

28:48

would be kind of packaged differently, and it

28:50

was really labor intensive, very

28:52

very expensive. So they moved to the standardized

28:55

container shipping and that was

28:57

supposed to lead to more efficiencies, which it

28:59

did did, but then of course the shipping

29:01

companies kind of got ahead of themselves stacked

29:04

as many containers as possible, and

29:06

eventually the economy of scale just kind

29:08

of goes away because the ports

29:11

aren't set up to handle it. Absolutely

29:14

super interesting to think about like this sort

29:16

of the different legs of the system and

29:19

how economies of scale and one part create

29:21

dis economies of skill elsewhere

29:24

in the systems. And it also again

29:26

this really helped we understand the situations.

29:29

So like there's so much inbound

29:32

demand for US uh

29:35

for Chinese goods coming to the US, Like we know

29:37

this, it's voracious. There is some export

29:40

activity obviously, as he mentioned, there's

29:42

soybeans and a few other agricultural goods,

29:44

so it's not entirely one directional. But

29:47

in this situation in

29:49

which there is a pretty big opportunity

29:52

cost of not racing back to China and getting

29:54

more goods, and you have

29:56

the delays already at the ports because

29:59

there's a bunch of ships because of the logistical issues,

30:01

this idea like nobody wants to sit around and

30:03

wait for all the soybeans to like fill

30:06

up maybe a quarter or a third full

30:08

vessel, so everyone just races back. Very

30:12

clear example of how messed up the whole situation

30:14

is right now. Yeah, absolutely, And I guess

30:16

it gets back to this idea that no one expected

30:19

a global pandemic in this way

30:22

and people hadn't really been building

30:24

supply chains that would be robust

30:26

enough to take it into account, which is kind of understandable,

30:29

but again, you wonder how much

30:31

that's going to change. Absolutely, we'll

30:34

see. We'll get him back on in a couple of years. Yes,

30:37

Okay, let's leave it there, let's save

30:39

it there. This has been another episode

30:42

of the All Thoughts podcast. I'm Tracy Alloway.

30:44

You can follow me on Twitter at Tracy

30:46

Alloway, and I'm Joe Wisntal.

30:49

You can follow me on Twitter at

30:51

the Stalwart and check out our guest Mark Levinson's

30:54

book The Box and the sequel

30:56

Outside the Box, and be

30:58

sure to follow a producer, Laura Carlson. She's

31:01

at Laura M. Carlson. Follow

31:03

the Bloomberg head of podcast, Francesco

31:05

Levi at Francesca Today, and

31:07

check out all of our podcasts at Bloomberg Onto

31:10

the handle ad Podcasts. Thanks

31:12

for listening.

Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

- Official Episode Pageomny.fm

- Download Audio Filehttps://chtbl.com/track/5899E/podtrac.com/pts/redirect.mp3/traffic.omny.fm/d/clips/e73c998e-6e60-432f-8610-ae210140c5b1/8a94442e-5a74-4fa2-8b8d-ae27003a8d6b/6bd59940-9cf7-40e9-97e7-ae2700445c38/audio.mp3?utm_source=Podcast&in_playlist=982f5071-765c-403d-969d-ae27003a8d83

Episode Tags

Claim and edit this page to your liking.

Unlock more with Podchaser Pro

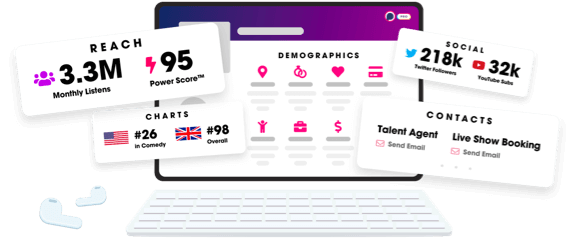

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us