Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:01

Welcome to Jewelry Making Tips with Metals mith

0:04

Society the ultimate podcast for anyone

0:06

passionate about the art of jewelry making

0:08

. I'm your host , Corkie Bolton . Metals

0:10

mith Society is a community on Instagram

0:12

that has over 240,000

0:15

individuals , from professional jewelers

0:17

to small business artisans , hobbyists

0:19

, students and even those curious looky-loos

0:22

eager to learn about jewelry making . Together

0:25

we share tips , kindness and support

0:27

. In this podcast , I will

0:29

discuss tips from the Instagram page

0:31

, provide deeper insights , address

0:33

questions and share bonus tips that

0:35

often surface in the comments section . So

0:38

, whether you've been making jewelry for a while

0:40

or you're just starting your jewelry making journey

0:42

, this podcast is your go-to

0:44

resource for all the jewelry making

0:47

tips . So grab your tools , dust

0:49

off your workbench and join me In

0:54

today's episode . I'm excited to talk

0:56

about gold . Now , if

0:58

you're someone that's been working in silver and

1:00

you're interested in working in gold , but perhaps

1:03

you're a little nervous due to the high cost

1:05

, hopefully this episode will

1:07

help you feel a little bit more comfortable

1:09

with getting started . Before

1:12

we jump into today's episode , I want to tell you about

1:14

my favorite work pants . They're

1:16

made by Dovetail Workwear . These

1:19

pants are not only cute and comfortable , but

1:21

they're super durable , perfect for working in the

1:23

jewelry studio , and Dovetail

1:25

is offering our community $10 off

1:27

your order with code METALSMITHSOCIETY

1:30

. So head over to dovetailworkwear . com/

1:33

METALSMITHSOCIETY and you can save 10%

1:35

off your first pair of work pants

1:37

. I want to begin today's episode

1:40

by letting you know I'm not a master

1:42

goldsmith and I'm totally cool

1:44

admitting that . When I went

1:46

to college for jewelry making

1:48

back in the early 2000s , I

1:50

was on a budget , so

1:53

my experience working in gold

1:55

was fairly limited . And then over the

1:57

years , as I developed my own

1:59

jewelry line , corky bolt and jewelry , due

2:01

to the expenses of the materials

2:04

I was working primarily in silver

2:06

for many years , but I would dabble

2:08

in some 14K and some

2:10

customs . And over the

2:12

years , as I've been studying engraving

2:15

and diamond setting , I've

2:17

become way more comfortable working

2:20

in gold . I was also fortunate

2:22

enough to be able to attend Metalsmiths's

2:25

in Florence this past October Shoutouts

2:28

to Monica . This trip to Italy

2:30

involved me working with a master

2:32

Florentine goldsmith for a week , and

2:35

that was truly amazing

2:37

. Recently I

2:39

made a pretty big decision for my business . I

2:41

decided that I was going to work exclusively

2:44

in gold . If you want to check out my

2:46

work , I will put a link to my website

2:48

in the show notes corkie bolton jewelry . com

2:51

and to touch upon

2:53

that briefly , there is

2:55

more profit in gold

2:57

jewelry and , as someone who

2:59

dedicates most of their time to Metalsmith

3:02

society , this podcast

3:04

and helping others learn about jewelry

3:06

making , my time at the bench is limited , and

3:09

so , if I'm only going to make a few

3:11

pieces of jewelry a month , it makes sense

3:13

for me to work in gold , and so I

3:15

wanted to pass on

3:17

some of the things that I've learned , hopefully

3:20

help some of you take the next steps

3:22

to working in gold , if that's what you're interested

3:24

in . So let's get started

3:26

. I'm going to be talking today

3:28

about 18 carat yellow gold

3:31

and 14 carat yellow gold , and

3:33

that's because these are the metals that I

3:35

use . Golds come in a

3:37

rainbow of alloys and

3:40

red golds and yellow golds

3:42

and a bunch of other alloys that

3:44

you can imagine , but pretty

3:46

common to work in 18

3:48

carat or 14 carat yellow . So

3:50

, to define them , 18 carat

3:52

gold contains 75%

3:54

gold , while 14 carat

3:56

gold contains 58.3%

3:59

gold . Now , because that 14

4:01

carat contains a higher percentage of alloyed

4:03

metals like copper , it provides

4:05

more durability and resistance to wear

4:07

and tear , but it's also a little

4:10

less yellow in its color . I

4:13

buy my gold primarily from

4:15

Stuller and Rio Grande , and

4:17

when it comes to buying it , it's a very

4:20

similar experience to silver , except for the

4:22

cost , of course , but you can buy

4:24

it in sheet form , tube , wire

4:27

, decorative wire . So

4:29

really anything that you can

4:31

purchase for silver you can typically

4:33

also find in gold . The

4:35

other thing you need to purchase when

4:38

you start to work in gold is

4:40

gold solder . Now , gold solder

4:42

comes in two forms there's plum

4:45

solder and there's repair solder . Plum

4:47

solder is what you're gonna wanna purchase when

4:50

you're fabricating . It's

4:52

equivalent to the carat value of

4:54

the gold you're working in . So , for example , the 14

4:56

carat plum has that 58.3%

4:59

pure gold in its formulation

5:01

. The repair solder is

5:03

really only gonna be for if

5:05

you're reattaching a prong or you're sizing

5:07

a ring , and I , quite

5:10

frankly , don't use it . It's gonna

5:12

look more white and

5:15

have a decreased carat value . So

5:17

you're definitely gonna wanna purchase the plum . Now

5:20

, when it comes to the

5:22

actual , which solder do I

5:24

purchase ? You use the same

5:26

step down soldering procedure as you

5:29

would in silver , Meaning your first

5:31

seam you should start with a hard solder

5:33

and then subsequent seams you could

5:35

go to medium . I personally

5:38

don't tend to use the easy yellow

5:40

gold solder because I noticed that it

5:42

does have a slightly more

5:44

white color and appearance , which

5:47

will stand out in my solder seam . Next

5:50

we can talk about oxidation and the difference

5:52

between gold and silver . Most

5:54

gold alloys don't oxidize

5:56

as much as silver when they're soldered

5:59

or annealed properly , so that actually

6:01

makes soldering gold kind of easier . The

6:04

oxides that do form on the surface will generally

6:06

come off in your pickle and

6:08

you can lightly buff them off as well . Let's

6:11

talk about fluxes . To

6:14

protect your gold alloys . You wanna

6:16

use a barrier flux ? Barrier

6:18

flux can be made by mixing

6:20

50-50 boric acid

6:22

with methyl alcohol , or you

6:24

can buy a commercial one like fire

6:26

scoff or supernil . Now

6:29

that's any time you're heating the metal . So

6:31

even when you're annealing , it doesn't hurt to

6:33

coat it with a barrier

6:35

flux . You

6:38

will also need to use a flow flux

6:40

when you're soldering . That could

6:42

be handy flux or

6:44

mighty flux . Before we talk

6:46

a little bit more about soldering gold , I

6:48

want to touch back on annealing . Annealing

6:51

is essentially the same as when you're annealing your

6:53

silver , but with yellow gold you're going

6:55

to bring the metal to more of a visible

6:58

cherry red and you want to make sure that

7:00

you anneal nice and evenly

7:02

. When it comes to the equipment

7:04

that you're going to use to solder gold . It's going

7:06

to be the same as your silver . However

7:09

, a lot of goldsmiths recommend working

7:11

with a dual gas torch because

7:13

the dual gas torch systems

7:16

have smaller , hotter flames

7:18

. When it comes to your soldering surface

7:21

, you just want to make sure , if you work both in silver

7:23

and gold , that your surfaces are clean

7:25

. You don't want a rogue chip of silver

7:27

solder to end up splattering onto

7:29

your gold piece as an example . That's

7:31

very annoying to remove . The

7:33

same rules apply when soldering

7:36

gold as to soldering silver

7:38

. You want your seam to be nice

7:40

and tight . One little difference

7:43

is , after you do your barrier flux

7:45

, you dip it in your boric

7:47

acid , methyl alcohol mix or one

7:50

of those commercial ones . You are

7:52

going to apply that paste flux

7:54

or mighty flux more

7:56

on the actual seam itself . You

7:58

are going to concentrate your flame

8:01

directly onto the seam that you're soldering

8:03

. When working in gold , just keep your

8:05

torch flame there , paying attention

8:08

, watching the metal for

8:10

any colors that it's changing . Then , when you

8:12

see that solder start to flow , just

8:14

gently pull that flame back . Your

8:17

experience soldering your gold

8:19

is going to be very similar to your silver

8:21

. I think you've got this

8:23

. You're going to pickle as you normally

8:25

would . Now we can move

8:27

on to talking about other aspects of working

8:30

in gold . When

8:32

you're , let's say , sawing and filing

8:34

gold , one hot tip is

8:37

you want to make sure that you collect every

8:40

single piece of dust , because

8:42

the gold is substantially more valuable

8:45

than the silver . I mean , we should all be collecting

8:47

all of our dust anyhow , but when it comes

8:49

to working in gold , one tip that I picked

8:51

up when I was at Metalsmith's in Florence

8:54

is putting a piece of tissue

8:56

paper in your bench drawer and that

8:58

allows every single piece of dust

9:00

to get collected so that you can later recycle

9:03

it within your own studio or send it to

9:05

a refiner . The designing

9:08

aspect of working in gold you

9:10

want to design with your budget in mind

9:12

. In silver , pieces

9:15

can be a little bit thicker . You're

9:17

not going to feel that as much in your wallet

9:20

. But when it comes to the gold , you can

9:22

save money just by determining the

9:24

thinnest gauge you can get away with . That will

9:26

still give you durability . Of course

9:28

, fabrication and forming with

9:30

gold is the same as working in silver . You

9:32

just want to pay attention to when your gold needs

9:35

annealing . You know , go back and

9:37

anneal it . Get it to that nice cherry

9:39

red , make sure it's nice and even and

9:42

polishing . Now a

9:44

tip I would recommend is keeping separate

9:46

bits and polishing buffs for your

9:48

gold work , because little flecks of metal

9:50

get embedded in there . So if a

9:53

buff , for example , had a lot of silver embedded

9:55

on it and then you used it on your gold pieces

9:57

, there could be some cross contamination . So

9:59

once you've decided this is going to be a gold

10:01

buff , take a Sharpie and write gold on

10:04

it , and that way you can keep that

10:06

separate . If you want

10:08

to get started working in gold but don't

10:10

have a ton of money to invest , I

10:12

have two different suggestions . One

10:14

is you can start to add little gold

10:16

components to your silver pieces . This

10:19

can provide some beautiful contrast

10:21

and provide greater

10:23

value to your work without totally

10:25

breaking the bank . Another

10:27

way you can do that is you can have gold

10:30

bezels around your stone but

10:32

have the back plate be silver . This

10:35

wouldn't be jewelry making tips with Corkie Bolton

10:37

if I didn't share about a tip that was shared

10:39

by our community and talk about it a

10:41

little bit more in depth . Back

10:43

in 2019 , Susan Fawman shared

10:45

a tip about soldering a gold

10:47

bezel to a silver back plate and

10:50

one of the main things that is

10:52

shown in this tip is a

10:54

setup which allows you to heat

10:57

the piece from the bottom , focusing

10:59

your heat on the silver back plate so

11:02

as not to melt the gold bezel . I

11:04

have to say that one of the top comments

11:06

is super helpful . It talks

11:08

about using potentially

11:11

18K or 22K

11:13

for the bezel because they are

11:15

much easier to set

11:17

than 14K , and I can

11:19

attest to this personally . And it's

11:21

also mentioned that you might want to end

11:24

up using silver medium

11:26

solder to solder the back

11:28

plate to the bezel . You'll want to be

11:30

mindful to not use an excess of solder

11:33

in general , because you don't want the

11:35

silver solder to go up onto the gold bezel

11:37

, but I think if you're heating it from the back

11:39

plate and you're pulling that

11:41

solder down around

11:43

the bezel , you shouldn't have a problem , and

11:45

I think this is great advice . I

11:47

hope today's episode about gold was helpful

11:50

to you and if you have more information

11:52

on working in gold and want to submit a tip , I

11:54

would love if you emailed it to me over at

11:56

tips at metalsmithsocietycom

11:58

. I'll add all this info in today's

12:01

show notes . I so appreciate you joining

12:03

me and I'll see you next time .

From The Podcast

Jewelry Making Tips with Metalsmith Society

Metalsmith Society is a community on Instagram where jewelers share jewelry making tips. On this podcast Metalsmith Society founder and author Corkie Bolton discusses tips from the Instagram page, provider deeper insights, answers questions, and highlights bonus content often shared by community members in the comment section.Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

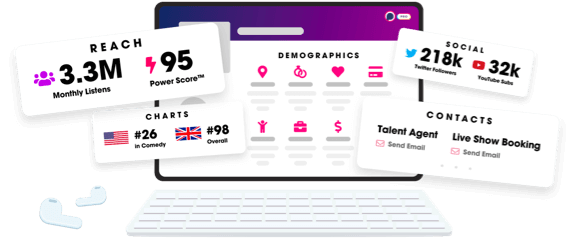

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us