Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:02

This is MIT Technology

0:04

Review.

0:11

From the cornfields of Iowa

0:13

to outer space, scientists are

0:15

building a world where plants and machines

0:17

communicate their needs with us and

0:20

each other in real time.

0:21

Are you ready? I'm

0:24

ready. Okay.

0:28

We're inside an experimental tractor on a test

0:30

farm that belongs to John Deere. So

0:33

we're sitting in a 8RX tractor, 410 horsepower.

0:38

This machine we're in is loaded with

0:40

tech. It has self-driving capability.

0:42

Joe Leifer is the senior product

0:45

manager of Autonomy. This machine

0:47

also has the capability to run full infield

0:49

autonomy. Just through the click of a

0:52

button here on this lever, right, I can change

0:54

ultimately the ground speed that we're running at.

0:56

It can run in straight rows or curved

0:58

ones, stay within the boundaries of a field,

1:01

and knows where it should place seats. So

1:03

you've got a fair number of sensors,

1:05

cameras. Absolutely, yeah. It's

1:07

equipped with six stereo camera pairs, three

1:10

on the front of the tractor, three around the back of the

1:12

cab. We have two NVIDIA

1:14

Jetson GPUs that are classifying

1:17

the world around us as we run in full autonomy

1:19

mode. So we just came to a stop,

1:21

and I'm going to power down the tractor here now.

1:29

In some ways, AI

1:30

has arrived at scale on the farm. A

1:33

majority of farmers now use sensors and

1:35

digital technologies that collect data,

1:37

and most tools that analyze that data also

1:40

use AI. But it's still early

1:42

days for other forms, including machine

1:45

vision.

1:46

I imagine a world within the next 10

1:48

years where all of these vehicles

1:51

literally have eyes and maybe

1:53

ears. Those eyes and ears,

1:55

those cameras, those sensors

1:58

are powered by machine learning.

3:57

years.

4:01

It's looking for is the machine

4:03

being a little bit too rough on the inside and

4:05

damaging the kernels. And if it is,

4:07

it begins to make adjustments to its mechanical

4:09

systems. And that's what you'll see back

4:11

here. All these mechanisms are meant to just

4:14

distribute all of that residue

4:16

in an even fashion because another

4:18

job of the combine is to get the ground ready

4:21

for next year. So by evenly distributing

4:23

all the residue, that becomes essentially

4:26

fertilizer for next year's crop.

4:28

Not all of this is done without the vehicle

4:31

ever stopping. And then this big tube,

4:33

this big auger above us, folds

4:35

out basically 90 degrees

4:38

perpendicular to the vehicle. And

4:40

then a tractor pulls up next to it with

4:42

another wagon. And then the grain

4:44

that is stored here is transported from

4:47

the machine through that auger to another vehicle

4:49

pulling a wagon. Looks like

4:51

cameras or sensors up on the arm as

4:53

well. Oh yes.

4:54

One of the pain points of farmers in the past

4:56

was from the cab of this vehicle,

4:59

from the operator station of this vehicle, it's

5:01

sometimes hard to see because the

5:03

tractor may be far away and it's dusty. So

5:05

we've built a machine vision system that helps

5:08

aim

5:09

where that auger dumps the corn.

5:12

So shall we hop on? Please. Let's

5:14

do it. All right. But it's more

5:17

of a climb than a hop. This machine towers over the both

5:19

of us and the latter feels at least

5:21

a few stories tall. And

5:24

why don't I let you jump in the driver's seat?

5:26

Ooh. Thank you.

5:29

We are sitting now in the cab,

5:31

the operator station. This vehicle

5:34

has 17,000 parts and all of those 17,000

5:36

parts have to work in synchrony

5:38

to essentially

5:42

create what we refer to as a factory on wheels.

5:44

Up inside the combine, I'm able to get a

5:47

better sense of how it works. He

5:49

describes how AI talks to mechanical

5:51

systems in real time to make

5:53

sure the harvest, in this case corn kernels,

5:56

isn't damaged. It's also recording

5:58

the crops quality and yield.

6:00

and it provides farmers with a report card,

6:02

so to speak, called a yield map that

6:05

allows them to assess their performance.

6:07

In the 90s, we talked about one meter

6:09

accuracy. In the 2000s, we would talk

6:12

a few inches. We

6:14

are now at a point where the accuracy of

6:17

our GPS solutions is

6:19

less than one inch, 99% of the time.

6:22

Which matters when you're placing

6:24

something as small as a seed. It matters a

6:26

ton. And actually, if you put

6:29

two seeds

6:30

next to each other, but you

6:32

put them too close to each other, they

6:35

begin to compete for nutrients right away.

6:38

If you space them apart just enough,

6:40

then each one kind of gets their own little ground

6:42

and they grow the most healthy.

6:47

A

6:47

common misperception of farmers is that

6:49

they reject new technology or their

6:52

late adopters. But he says that's far

6:54

from true. After all, farmers

6:56

accepted self-driving technology much

6:58

earlier than the rest of us. But they

7:00

do have what he calls a show-me culture.

7:03

They need to know these tools work and will

7:05

work for them on their land and

7:07

for their crops.

7:10

Let's say there's a farmer that farms

7:13

a thousand acres just to make it a round number. What

7:16

you'll see farmers do is test

7:19

out technologies in small portions

7:21

of their farms. So they'll say, hey, I'm gonna take this small

7:24

field that I have and try this

7:26

out for this year and see if it scales. They

7:28

don't just do that with equipment. They do that also

7:30

with seeds and with chemicals and

7:33

even new agronomic practices. So

7:35

they wanna understand how that

7:37

a new practice or a new technology would scale

7:39

across their operation. He

7:42

believes AI on the farm through

7:44

the lens of data analytics has arrived

7:46

at scale. But

7:48

we're still just getting started with machine

7:50

vision and other forms of AI.

7:53

Right now, the machine

7:56

reactively makes decisions based

7:59

on what it injects.

7:59

and it optimizes itself based

8:02

on what's inside of it. As we look toward the

8:04

future, with more machine vision capabilities,

8:07

the plan is to begin to look ahead of the machine

8:09

with cameras and be able to predict

8:11

what's ahead of it. So you can actually,

8:14

for example, measure the height of the

8:16

crop ahead of the machine, and the machine

8:18

can almost begin to configure itself

8:21

proactively.

8:22

Another way to do this is through satellites.

8:25

That information

8:28

can be then transferred to the machine via

8:30

the operations center, and now the machine

8:32

has knowledge of what that satellite

8:34

saw, and again, can begin to proactively

8:37

configure itself before it actually

8:39

gets to the crop. We believe that

8:42

persistent and reliable connectivity

8:44

is critical to agriculture. It's not just moving

8:46

data off the vehicle, it allows them to

8:48

have access to data that could be moved

8:51

from other places into the vehicle so that they

8:53

become more intelligent in real time.

8:54

Right, so that if you have multiple pieces of equipment,

8:57

they can essentially talk to each other. Exactly, exactly.

9:03

After the break, plants that have been genetically

9:06

modified to communicate their needs by

9:08

giving off new forms of light that can be

9:10

seen from outer space. You

9:15

can find links to our reporting in the show notes,

9:17

and you can support our journalism by going to

9:19

techreview.com slash subscribe.

9:23

We'll be back right after this. We're

9:30

mining soils in a rate

9:31

that's never been seen before. Those soils took thousands of years to develop, and

9:34

they might not be usable in 30 years,

9:37

and

9:37

people do not understand that. So we gotta do something, and

9:40

it's likely technology and the win-win that's

9:42

gonna save it, right? You have to make farmers more productive,

9:45

more profitable, more sustainable. You

9:48

can't take anything from the soil and

9:50

just throw it away. So we have to do something. We

9:52

have to do something about it. We have to do something

9:54

about it. We

9:55

have to do something about it. We have to do something about

9:57

it. develop

10:00

essentially complicated solutions that give them an

10:02

easy work around. I'm

10:05

Shelly Aranov, I'm the CEO and founder

10:07

of InnerPlant. We

10:10

create crops that can communicate what they need. So

10:12

let's start at the beginning, actually. We use 250

10:15

billion worth of chemicals every year, fertilizers,

10:18

pesticides. At least 30 percent of those

10:20

are misapplied, overapplied. At

10:22

the same time, we lose 20 percent of potential yields

10:25

to pathogens. So we have an inefficient system.

10:27

And the reason it happens is because farming is really

10:29

large. Right. An average farm is probably

10:31

the size of San Francisco. And

10:34

it's impossible to find problems at the right time. So

10:36

what farmers do is they hedge their bets, they

10:38

apply chemicals in advance on entire fields, and

10:41

the data clearly shows that that doesn't give you better

10:43

results. It just gives you more chemicals. So

10:46

what we do is we enable crops

10:48

to tell the farmers what they need.

10:50

This is achieved by genetically engineering

10:53

plants to give clear signals about what's

10:55

wrong with them. So it starts with the plant

10:57

itself. Plants already

10:59

react natively to stress. So

11:02

people think that plants are just stuck

11:04

and do nothing. They're super active in their environment

11:07

because they're stuck and they can't move. So,

11:09

for example, if a plant is eaten by insects,

11:12

it will actually start producing a new compound in

11:14

its leaves to make it taste bad. Or if

11:16

it doesn't have enough nitrogen, it's going to start mobilizing

11:18

its roots to be able to capture more nitrogen

11:21

from the soil. All these things happen

11:23

very early on and they're different reactions.

11:26

And we know them very well

11:27

because people have been studying them for a long time. But

11:29

they're all on the biological level, so you can't see

11:32

them. What we do is we code the plants

11:34

as they're reacting to that native stress. They're going

11:36

to start producing a new protein that signals

11:39

optically from the leaves.

11:40

There is a problem. I'm attacked by insects. I

11:42

have fungal pressure. I need more water. And

11:45

then we use sunlight, optical

11:48

equipment and algorithms to be able to

11:50

see those signals from anywhere from satellite imagery

11:52

and as close as, you know, a tractor sensor

11:54

in the field.

11:55

And this is how it works. What

11:57

we do is we go in. take

12:00

that piece of DNA and

12:02

we add something to it. We add the fluorescent

12:04

protein. And then what happens is that

12:07

when the plant starts activating that piece of DNA,

12:09

it's going to start producing the new fluorescent protein

12:11

that we taught them how to make. So that's really it. And

12:14

then it's embedded in the plants. So in

12:16

the next generation, they already have this line

12:18

of code. And they just know that when

12:21

they're responding to stress, they're going to start producing this

12:23

new protein. And

12:25

also, when the stress goes away, the protein

12:27

stops,

12:28

which means you have a signal that's on and off and

12:30

you know when problems are resolved.

12:32

What she's talking about is called solar-induced

12:35

fluorescence. It was discovered about

12:37

two centuries ago by a Scottish preacher

12:40

who figured out that when sunlight hits a green

12:42

alcoholic extract of laurel leaves, it

12:45

brings out a bright red light.

12:47

It's part of the photosynthesis process, but

12:50

not something the human eye can usually

12:52

see without help.

12:53

And the reason that's important is because if you just need

12:55

the sunlight, then you can do it from satellite

12:58

imagery. If you need another light source,

13:00

then you're going to have to be closer to the ground

13:02

and it's not scalable. And if you want to cover

13:04

oceans and the entire globe and large agriculture

13:08

land, you need that.

13:09

Before she got into the agricultural business,

13:12

she was in the food business.

13:13

An Israeli-style hummus brand in the Bay Area. And

13:16

at the peak of that, we're selling at about 300 stores. And

13:19

then I had my first daughter, and I thought,

13:21

I want to do more with life. I want to

13:24

make an impact. I want to do something that matters. I

13:26

really want to work with agriculture. I love food,

13:28

but I wanted to go back to where things start and

13:31

where a lot of impact could be done.

13:34

Do you want to see the demo? What you'll see,

13:36

if you put on the glasses.

13:40

And I'm putting on the

13:42

headphones. Feels like sunglasses

13:44

I'm putting on here. Oh, you kind of are. So

13:47

basically, what you'll see is we have two kind

13:49

of plants here. These are the regular plants,

13:51

and these are the sensor plants. Oh, wow. Exactly.

13:54

So they really glow. And here, if

13:56

you think about it, the laser and

13:58

the color.

15:38

This

16:00

one has the problem and I can treat just

16:02

in the places where I have the problem

16:05

and skip the guys that

16:07

do not.

16:08

First, he needs to understand the

16:11

way a plant responds to problems. One

16:13

way to do this is by grinding up infected

16:15

plants and comparing their gene expression

16:17

levels to healthy plants,

16:19

as the stressed plants will have turned on

16:21

a bunch of genes that help combat the

16:23

problem.

16:24

And once they know what those genes are,

16:27

they can add their color signal onto that process.

16:30

Yeah, go ahead, go in here. There's

16:33

no pathogens or anything in this one. At least we try

16:35

to keep the pathogens down. There are no

16:37

intentional pathogens in this growth chamber.

16:40

So we have tomatoes, rice

16:42

and soybeans in here right now. So

16:45

we're developing sensors for all of

16:47

these. If they come in here, we grow them in

16:49

here, we do the tests in the lab, and

16:51

then the best performing ones go out into

16:53

the field.

16:57

So that's sort of dirty. So that's

16:59

where we grow the plants in the soil. This is

17:01

where we grow the plants in tissue culture. So

17:03

this is more, well, called sterile,

17:06

but it's a cleaner environment. So here's

17:09

where they do the actual integration

17:12

of the genes into the plant. And

17:16

so we need to keep these guys sterile because they grow in

17:18

these tissue culture environments until

17:21

they're big enough to be moved over

17:23

into soil.

17:29

They are generating the plants. They

17:31

start from like little tiny clusters of cells

17:33

and then through different manipulations

17:36

of media. So I have this little cup here

17:38

with plants that they

17:40

grow up. Some of the plants that are

17:43

non-edited or non-changed

17:45

or transgenic, they turn white. They

17:48

don't live, but the ones that are starting to turn green, those are the

17:50

ones that will make it through. So they're in these little

17:52

sterile cups. So all this stuff in here is sterile. We

17:54

don't like to have to get the soil in here, not

17:57

until we can move across the way. And then

17:59

we take

17:59

them across the hall. and then we put them in dirt and then

18:01

eventually take them out to the greenhouse where we can collect seeds

18:04

and then in the next generation we can start

18:06

doing our

18:06

tests.

18:11

We do two detections currently,

18:14

so two different colors, and then we can do up to five.

18:17

Once again, Shelly Aronoff.

18:19

And the idea is to get to the point where we can tell farmers

18:21

everything they need in one seed. So

18:24

fungal, insect pressure, nitrogen,

18:26

phosphorus, potassium. And

18:29

the plan is to do this at scale. The

18:31

technology is embedded in the seeds, right? When the farmers

18:34

plant seeds, they're harvesting data and

18:36

they don't need to do anything else. It's just a line of code

18:38

in the seeds. So every single plant in

18:40

the field is emitting this information. It's

18:42

a living sensor. And then the idea

18:44

is first, salad imagery, because we want to make

18:47

sure that we can cover the globe really cost effectively.

18:49

And we're talking two and a half acre pixel

18:51

size. So we can look really, really small and

18:54

start seeing an infestation in the early days, for

18:56

example, if it's fungi.

18:58

So this is the starting point. We call that the scouting

19:00

tool.

19:00

But then once you get into the field, right, we're talking about

19:03

the OEMs and the tractors, then

19:05

you have another opportunity because you already know

19:07

you have a problem, but you have equipment

19:09

now that can literally look at every individual plant

19:12

and give it just what it needs.

19:15

Right? So in the really a few years into

19:17

the future, we can go into the field

19:19

and scan every plant knowing, for example,

19:21

there's a nitrogen stress somewhere,

19:24

but then still look at every individual plant and only

19:26

give the plants that need nitrogen, nitrogen

19:28

and the plants that are healthy for whatever reasons, those

19:31

can just be left alone. And

19:33

that will be, I believe, the most efficient

19:36

way we'll ever farm.

19:43

This mini series on satellites and farming

19:45

was reported and produced by me, Anthony

19:48

Green and Emma Silikens. It was edited

19:50

by Matt Hounen and our mix engineer is

19:52

Garrett Lang with original music by

19:55

Garrett Lang and Jacob Gorski. Thanks

19:58

for listening. I'm Jennifer Strong. This

20:05

is MIT Technology Review.

From The Podcast

In Machines We Trust

Host Jennifer Strong thoughtfully examines the far-reaching impact of artificial intelligence on our daily lives. Produced by MIT Technology Review, the podcast explores the rise of AI through the voices of people reckoning with the power of the technology, and by taking listeners up close with the inventors and founders whose ambitions are fueling the development of new forms of AI.Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

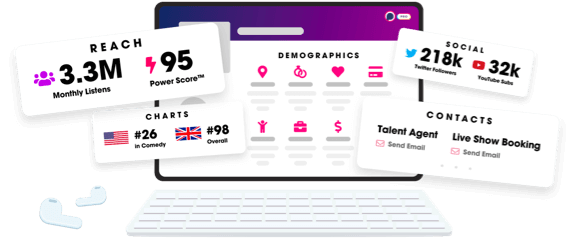

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us